Hotin-place recycling engine for pavement

A locomotive and geothermal technology, which is applied in the field of road repair, can solve the problems of inconvenient small projects, regenerative trains and hot repair machines are not suitable, and hot repair machines can only repair small pits and grooves, so as to save space and heat Easy temperature control and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

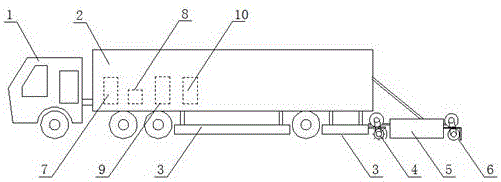

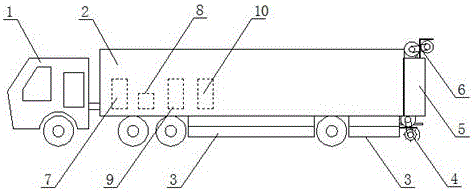

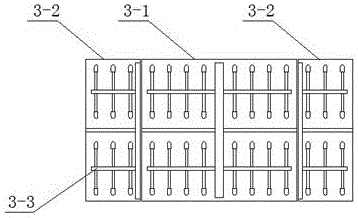

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] A locomotive for in-situ hot regeneration of road surfaces, comprising a tractor 1, a carriage 2, a road surface preheating system, a thermal milling device 4, an aggregate mixing system 5, and a material distribution leveling and paving system 6. An engine is installed in the tractor to drive the whole locomotive. The compartment 2 is connected to the rear of the tractor 1, and the compartment 2 is used to carry other equipment. The road surface preheating system is installed at the bottom of the compartment 2, the thermal milling device 4 is installed at the bottom of the compartment 2 and behind the road surface preheating system, the aggregate mixing system 5 and the distribution paving system are respectively installed behind the thermal milling device 4 in sequence department.

[0028] The compartment 2 also contains a generator set 8, a distribution box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com