A water tank drainage device utilizing pressure difference for drainage

A technology of drainage device and pressure difference, which is applied to water supply devices, flushing equipment with water tanks, flushing toilets, etc., can solve the problem that the force value of pulling and sealing the water plate needs to be large, the number of times of use of the power supply battery is shortened, and it is not conducive to practical use. and other problems, to achieve the effect of good siphon effect, simple structure and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

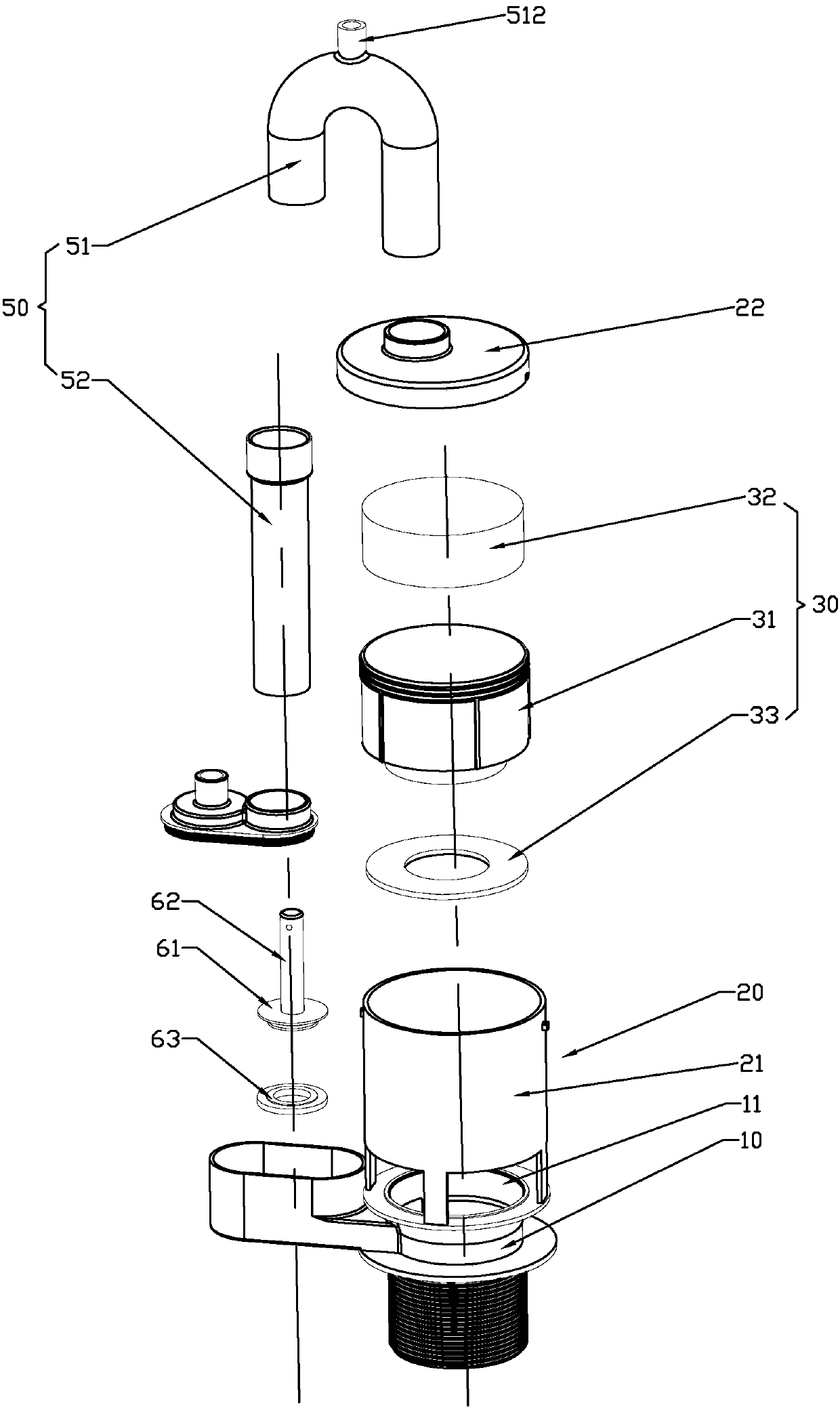

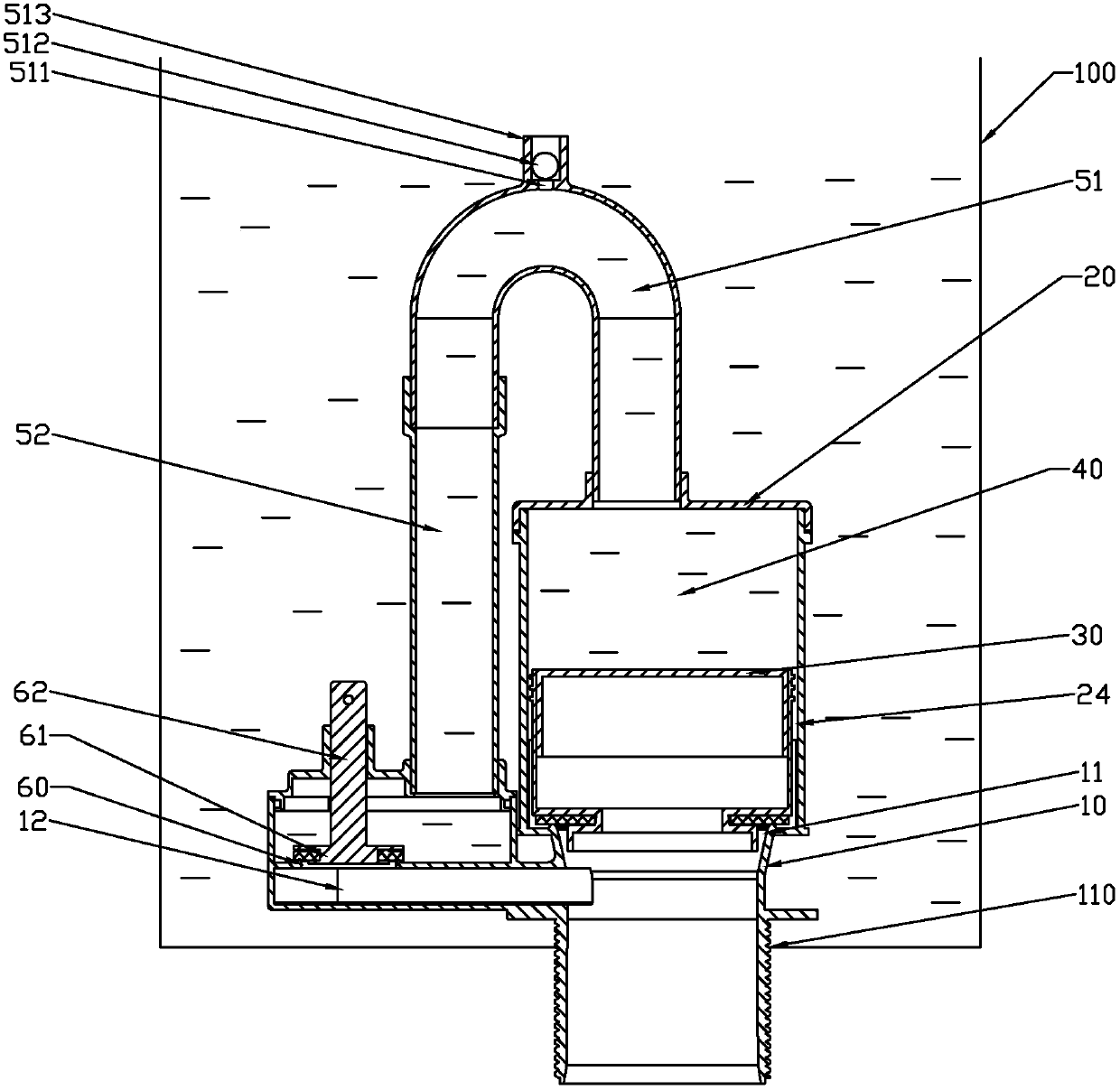

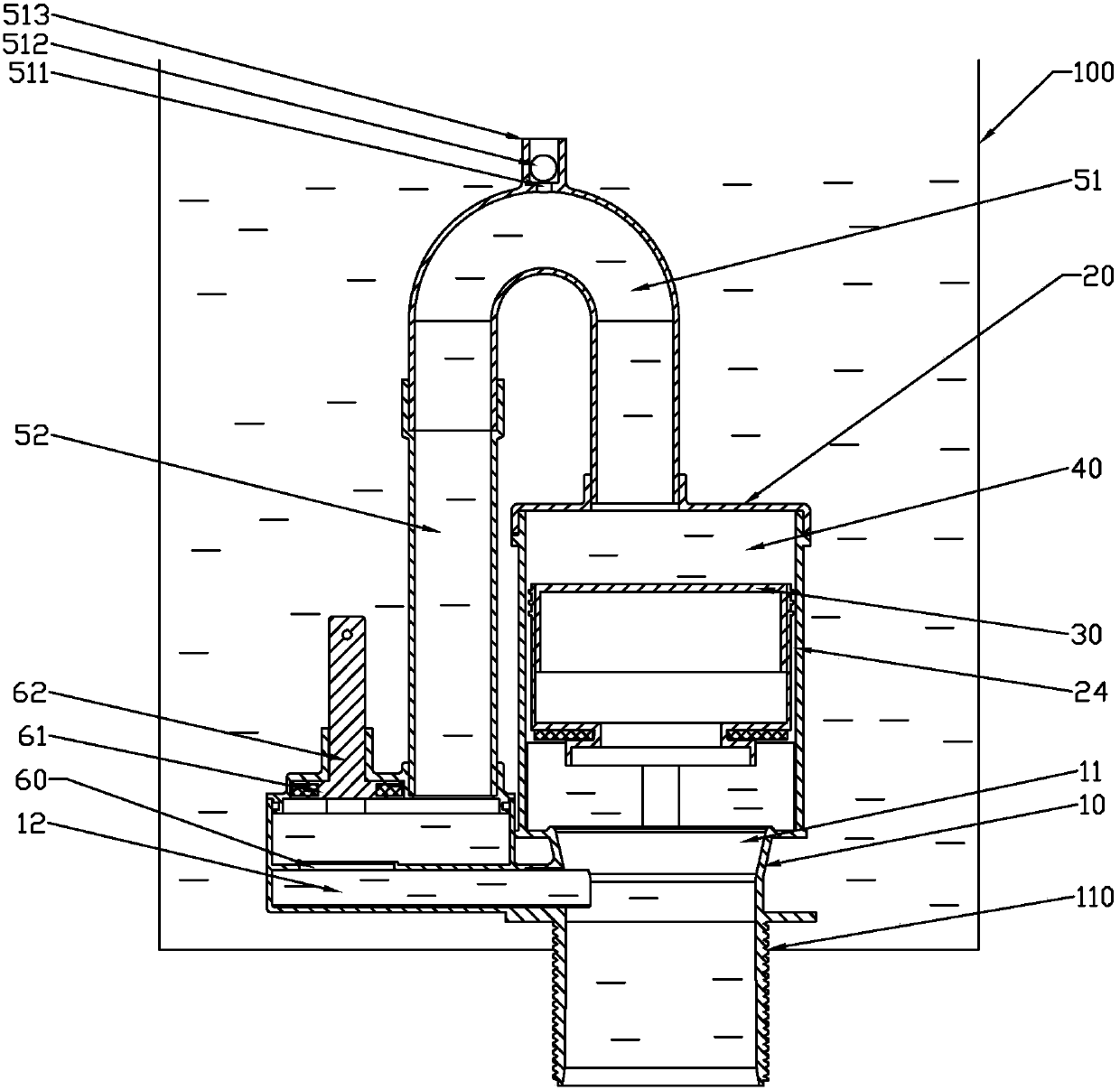

[0046] The first embodiment: (the pumping mechanism is a siphon assembly, and the siphon trigger assembly is manually controlled)

[0047] Such as Figure 1-3As shown, a water tank drainage device utilizing pressure difference in this embodiment includes a base 10, a casing 20, a floating body 30 and a pumping mechanism. The base 10 is fixed at the mounting hole 110 of the bottom wall of the water tank 100, and the drain 11 is provided on the base 10, which is also equivalent to that the drain 11 is arranged on the bottom wall of the water tank 100, or the base 10 may not be provided. , and the water outlet 11 is directly arranged on the bottom wall of the water tank 100 . The shell 20 is a hollow structure with an open bottom and is firmly connected with the base 10. In this embodiment, the shell 20 and the base 10 are integrally formed to achieve fixed fit. The bottom opening of the shell 20 is connected to the water outlet 11 and the inner cavity of the water tank They ar...

no. 2 example

[0055] Second embodiment: (the pumping mechanism is a siphon assembly, and the electric control chain moves to drive the siphon trigger assembly)

[0056] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that this embodiment controls the movement of the chain 64 through the electric drive mechanism to drive the movement of the valve plate 61, specifically, the valve plate 61 cooperates with one end of the chain 64 through the connecting rod 62 , the other end of the chain 64 is coordinated with an electric drive mechanism, the electric drive mechanism can be a motor, the electric control structure is simple and feasible, and it is convenient to use. Of course, here, the manual drive mechanism can also be selected to pull the chain 64, and the rest of the undescribed structures and The working principle is consistent with that of the first embodiment, and will not be repeated here.

no. 3 example

[0057] The third embodiment: (the pumping mechanism is a siphon assembly, and the movement of the float is electrically controlled to drive the siphon trigger assembly)

[0058] Such as Figure 5 and Figure 6 As shown, the difference between this embodiment and the first embodiment is that in this embodiment, the valve plate 61 is linked with a float 65 through a connecting rod 62, and the float 65 is fixed upward with a pressing rod 66, which is pressed down when an electric drive mechanism is closed. Press the rod 66 to sink the float 65 and drive the valve plate 61 to seal the flow port 60 through the connecting rod 62. When the electric drive mechanism is opened, release the pressure rod 66 to make the float 65 float up and drive the valve plate 61 to open through the connecting rod 62 The flow port 60, the electric drive mechanism can be a motor, the electric control structure is simple and feasible, and it is convenient to use.

[0059] The rest of the undescribed str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com