A steel bar measuring and positioning device and its construction method

A technology for positioning devices and steel bars, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems such as inaccurate positioning of steel bars, and achieve low production costs, strong applicability, and a wide range of operating and user groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

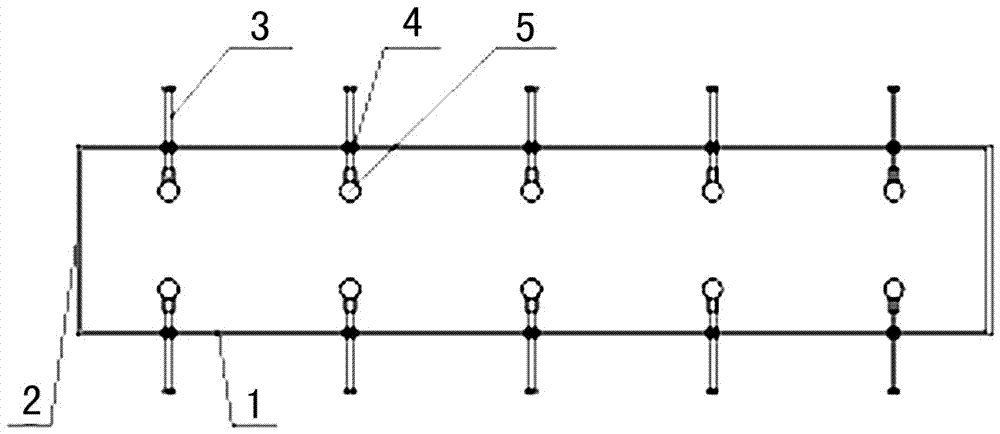

[0041] Embodiment one sees Figure 1 to Figure 8 As shown, the steel bar measuring and positioning device is used in the steel bar positioning construction of the wall.

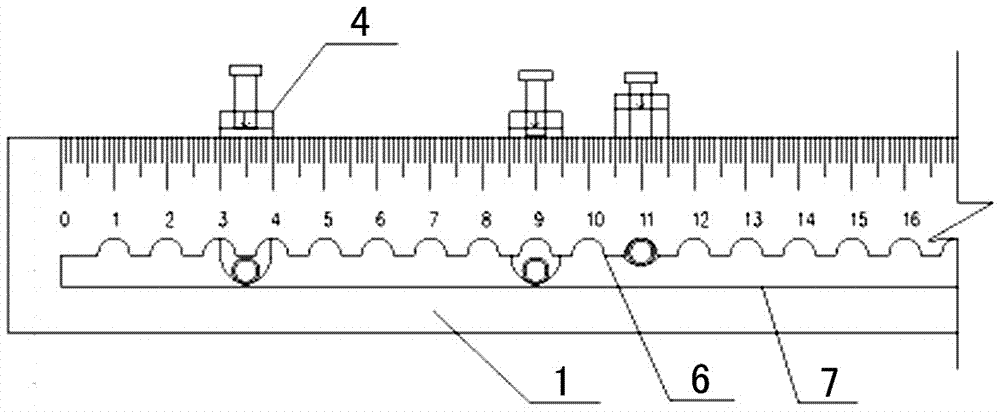

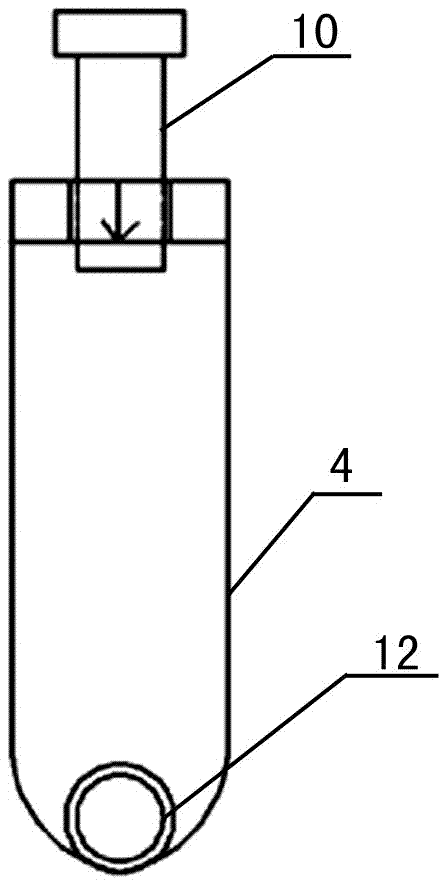

[0042] A steel bar measurement and positioning device, the positioning device is a rectangular frame formed by alternately connecting and enclosing two long-direction positioning rulers 1 and two short-direction positioning rulers 2 in sequence, and the long-direction positioning ruler 1 and the short-direction positioning ruler The ruler 2 is made of light and high-strength steel, and the long-direction positioning ruler 1 and the short-direction positioning ruler 2 are perpendicular to the same plane; wherein the long-direction positioning ruler 1 is movably connected with a mobile clip 4, and the moving The lower end of the clip 4 is horizontally connected with a positioning screw 3 , and the end of the positioning screw 3 is located in a rectangular frame and is connected with a positioning tube 5 .

[0...

Embodiment 2

[0057] Embodiment two see Figure 9 As shown, the difference from the first embodiment is that the steel bar measurement and positioning device is used in the steel bar positioning construction of the prefabricated column. Since the four sides of the prefabricated column have steel bars, the positioning device is sequentially connected by four longitudinal positioning rulers 1 The enclosed rectangular frame does not need to use the short positioning ruler 2, and a positioning rope is flexibly connected between the long positioning rulers on the opposite side, see Figure 2 to Figure 6 As shown, the structure of the longitudinal positioning ruler 1 and its connection relationship with the moving clip 4, the positioning screw 3, the positioning tube 5 and other components are the same as those in the first embodiment.

[0058] The working process of embodiment two is as follows:

[0059] Step 1: According to the diameter and quantity of steel bars at each measurement position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com