Membrane hearth structure of low-speed circulating fluidized bed boiler

A circulating fluidized bed and membrane wall technology, applied in the field of boilers, can solve problems such as damage to the central gas outlet, and achieve the effects of extending service life, safe and reliable water circulation, and solving expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

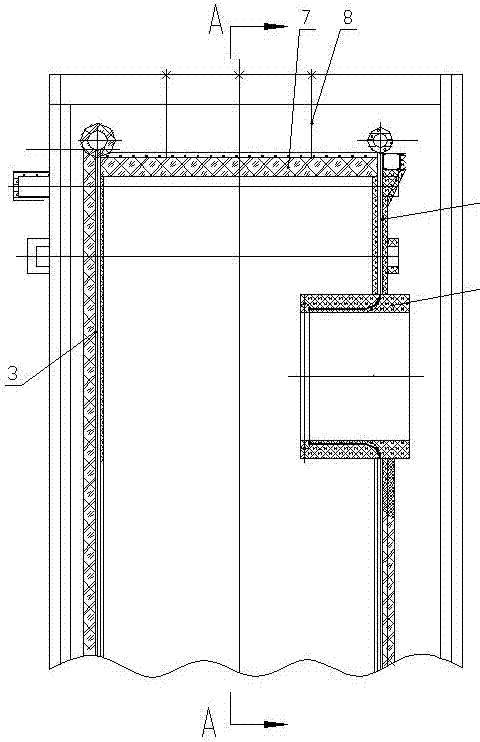

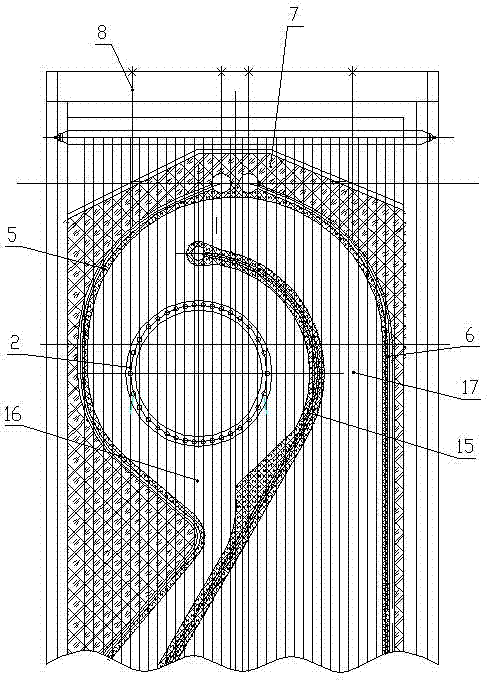

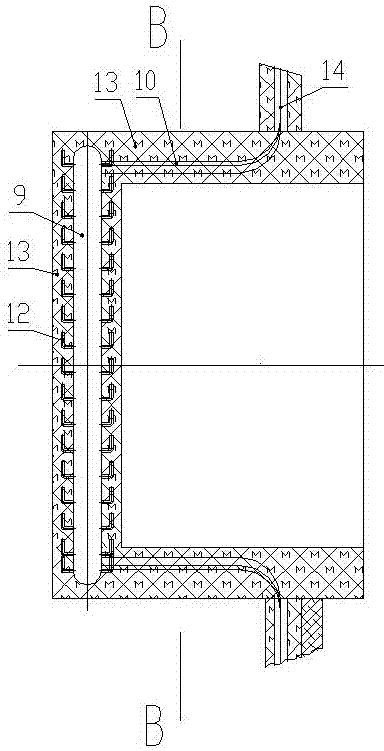

[0020] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the low-speed circulating fluidized bed boiler membrane hearth structure of the present invention includes a horizontal water-cooled separator, a central air outlet tube 2, a front membrane wall 3, a rear membrane wall 4, a left membrane wall 5, and a right membrane wall. The wall 6 and the membrane-type wall 7, the top of the membrane-type wall 7 is suspended in the boiler through the furnace hanging device 8, the center line of the center outlet tube 2 is set horizontally, and the front end of the center outlet tube 2 extends into the horizontal water-cooling separation Inside the device, the front membrane wall 3, the rear membrane wall 4 and the middle membrane wall 7 are all equipped with circulating water pipes 14, and the central air outlet 2 is arranged on the rear membrane wall 4, and the rear end of the central air outlet 2 extends out of the rear membrane wall 4.

[0021] The center outlet tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com