Device and method for regulating and controlling electric arc additive performance and forming stability in real time based on molten pool monitoring

A technology of additive forming and real-time control, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of harsh working environment, huge memory for storing pictures, and single viewing angle, so as to improve the quality of printed parts and reduce the burden of storage , Accurate information collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further described in detail below with reference to specific examples.

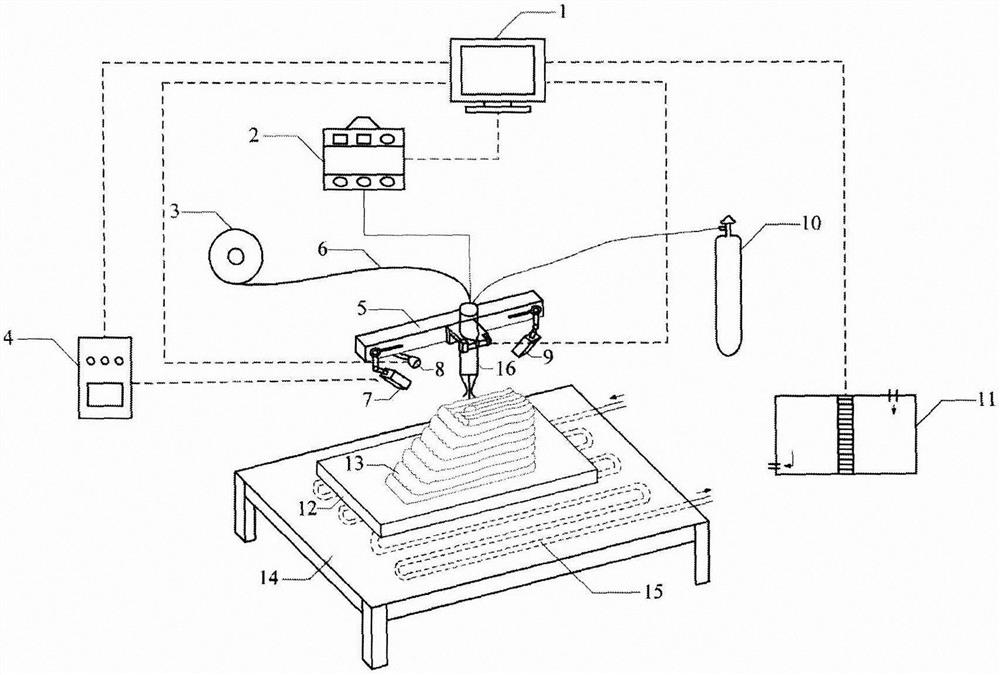

[0047] An example of the present invention provides a device for real-time regulation and control of arc additive forming stability based on molten pool monitoring, as follows figure 1 shown. Using the method of the present invention to print a certain type of variable-section single-wall wall, the details are as follows:

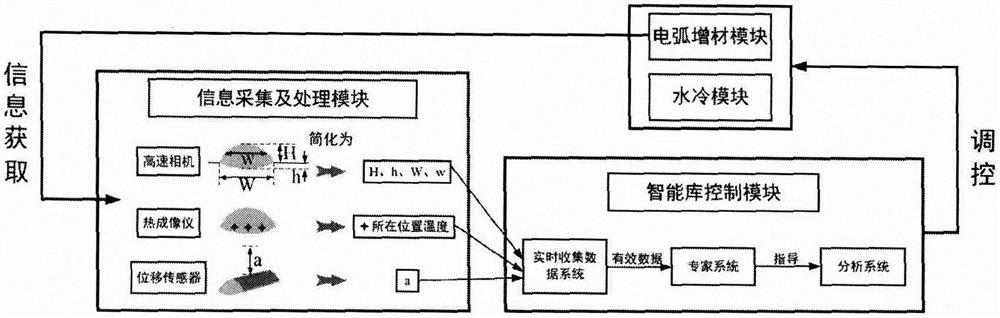

[0048] The invention includes: an arc additive module, an information acquisition and processing module, an intelligent library control module 1 and a water cooling module.

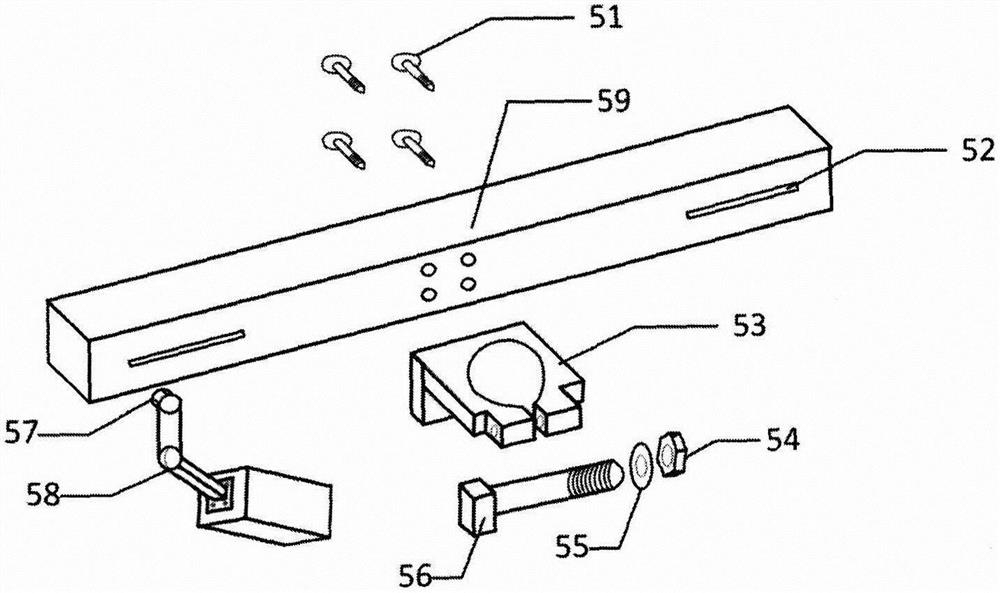

[0049]The arc additive module includes: a welding machine 2, a welding torch 16, a welding wire 6 and a fixture 5;

[0050] The welding torch 16 is used for obeying the instruction of the analysis system, and according to the set path planning and process parameters on the substrate, the welding wire is melted by the arc heat source and printed layer by layer until the sample prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com