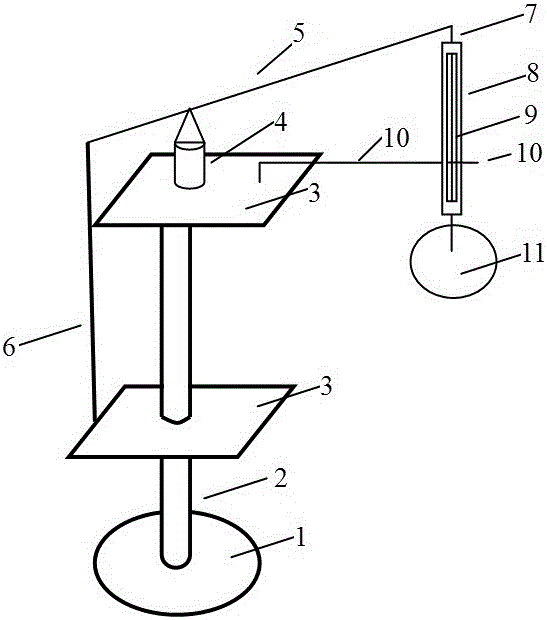

Method for measuring Young's modulus of metal wire by lever weighting

A Young's modulus, wire technology, applied in the field of physical parameter measurement, can solve problems such as difficulty in accuracy, measurement error, inability to approach the wire and fixture fixing points, etc., to reduce adjustment steps, save costs, and reduce quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A support rod 2 is fixed on a base 1, and a platform 3 is respectively fixed on the middle and top of the support rod 2 (the middle platform 3 can be replaced with a support rod, and the purpose of the middle platform 3 is to fix one end of the wire 6, which has this function Any device can be used, so cylindrical or cuboid hard rods are acceptable), metal wires generally vibrate when adding or subtracting weights, and the middle platform 3 protrudes 1-2cm to the left relative to the top platform 3, which is conducive to Ensure that the wire is in a vertical state, and ensure that when the wire is shaking, the upper end of the wire will generally not touch the edge of the top platform; a support column 4 is placed on the top platform 3, and there are three omnidirectional rotating wheels at the bottom of the support column 4 ( Not shown in the figure, three points determine a plane, three omnidirectional rotating wheels are a kind of stable structure, omnidirectional rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com