Method for examining water blocking effect of cracked surrounding rocks of tunnels after grouting

A test method, tunnel technology, applied in measurement devices, suspension and porous material analysis, instruments, etc., can solve problems such as characteristics that cannot reflect stress redistribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

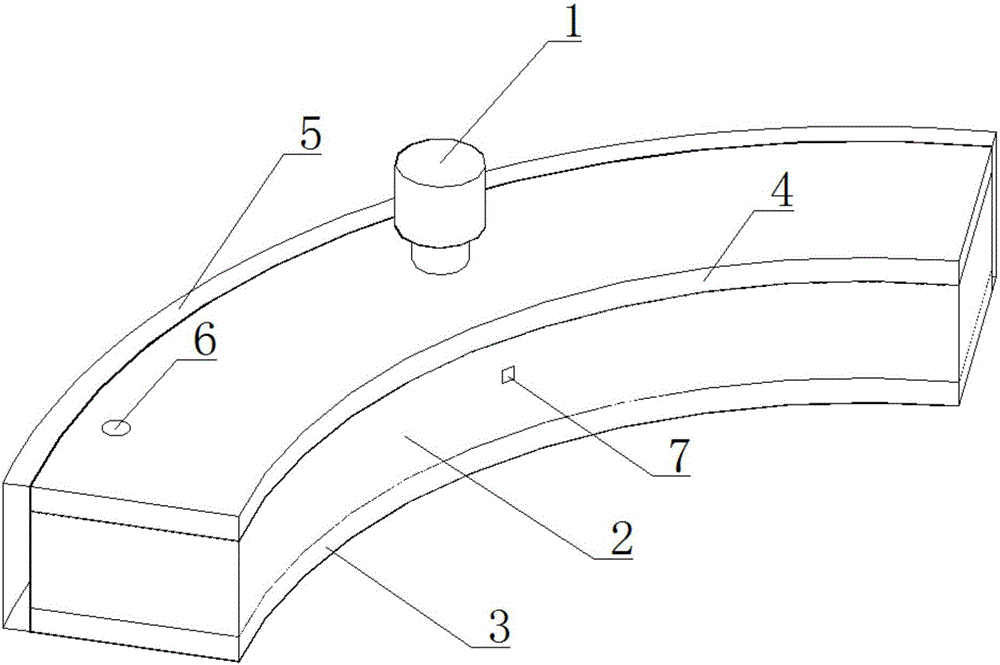

[0035] Example 1, such as Figure 1-4 As shown, a test method for testing the water blocking effect of the tunnel ruptured surrounding rock after grouting includes the following steps:

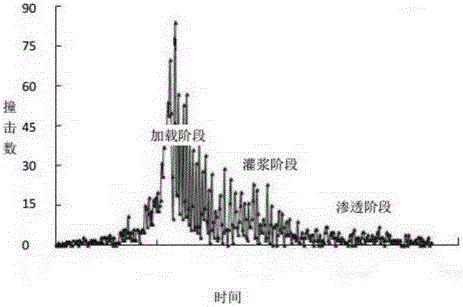

[0036] S1. Carry out circumferential loading on the sample 2 to form cracks on the sample, and record the acoustic emission signal during the loading process;

[0037] S2. Perform pressure grouting on the sample, and record acoustic emission signals during the grouting process;

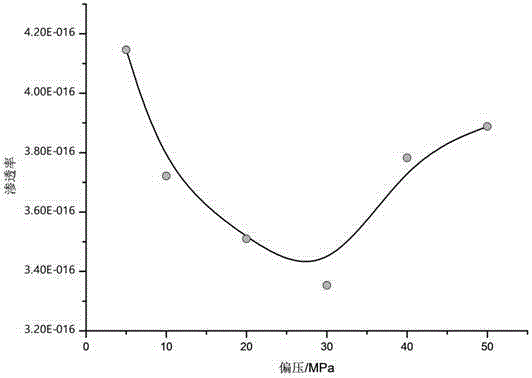

[0038] S3. Carry out a penetration test on the grouting body after the grouting is consolidated, and record the seepage flow and seepage pressure of the loading end face during the test.

Embodiment 2

[0039] Embodiment 2, on the basis of Embodiment 1, step S1 of the present invention comprises the following steps:

[0040] S11. Seal the front and rear sides of the sample 2 with the front sealing plate 4 and the rear sealing plate 3 respectively, the top of the sample 2 is sealed with the upper sealing plate 5, and the bottom is sealed with the lower sealing plate to keep the left and right sides of the sample loaded The end face is not sealed, and the acoustic emission probe 6 is pasted on the front and rear sides and the top and bottom sides of the sample;

[0041] S12. Place the sample in the loading device, and preload the left and right ends and the front and rear sides of the sample;

[0042] S13. Uniformly load the left and right ends and the front and rear sides of the sample at a loading rate of 0.02MPa / s until the given load, and then continue to load the left and right ends of the sample evenly at a loading rate of 0.02MPa / s until the given load is given. Constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com