Device and method for testing rock fracture seepage parameters under high temperature and high pressure conditions

A rock fracture, high temperature and high pressure technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not testing the heat transfer efficiency, not being able to test the permeability of non-filled fractures, and not being able to achieve accurate fractures Control and other issues, to achieve the effect of precise and meticulous test methods, prevention of cracking, and reliable test support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

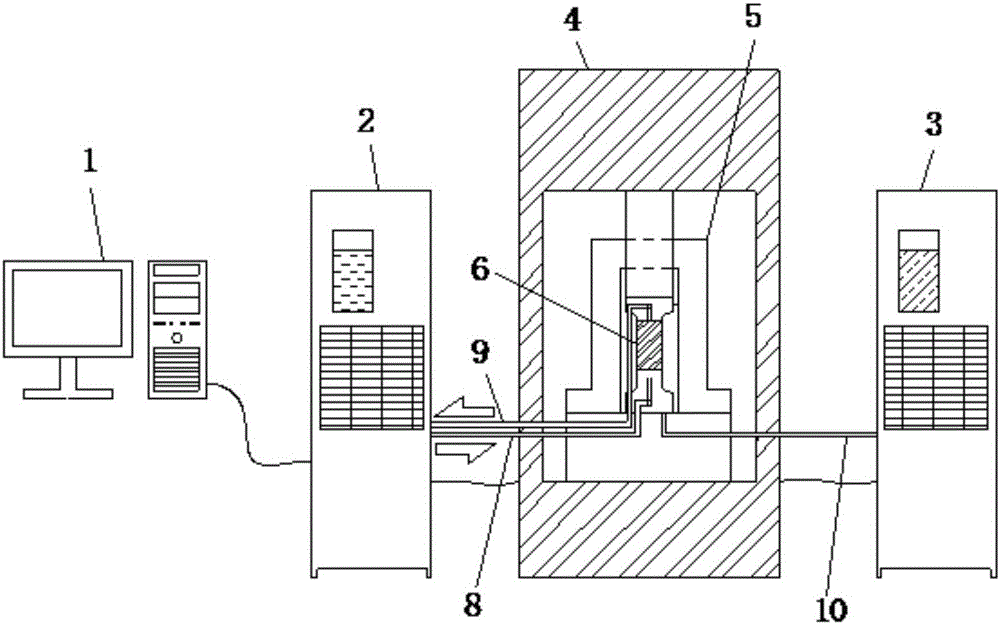

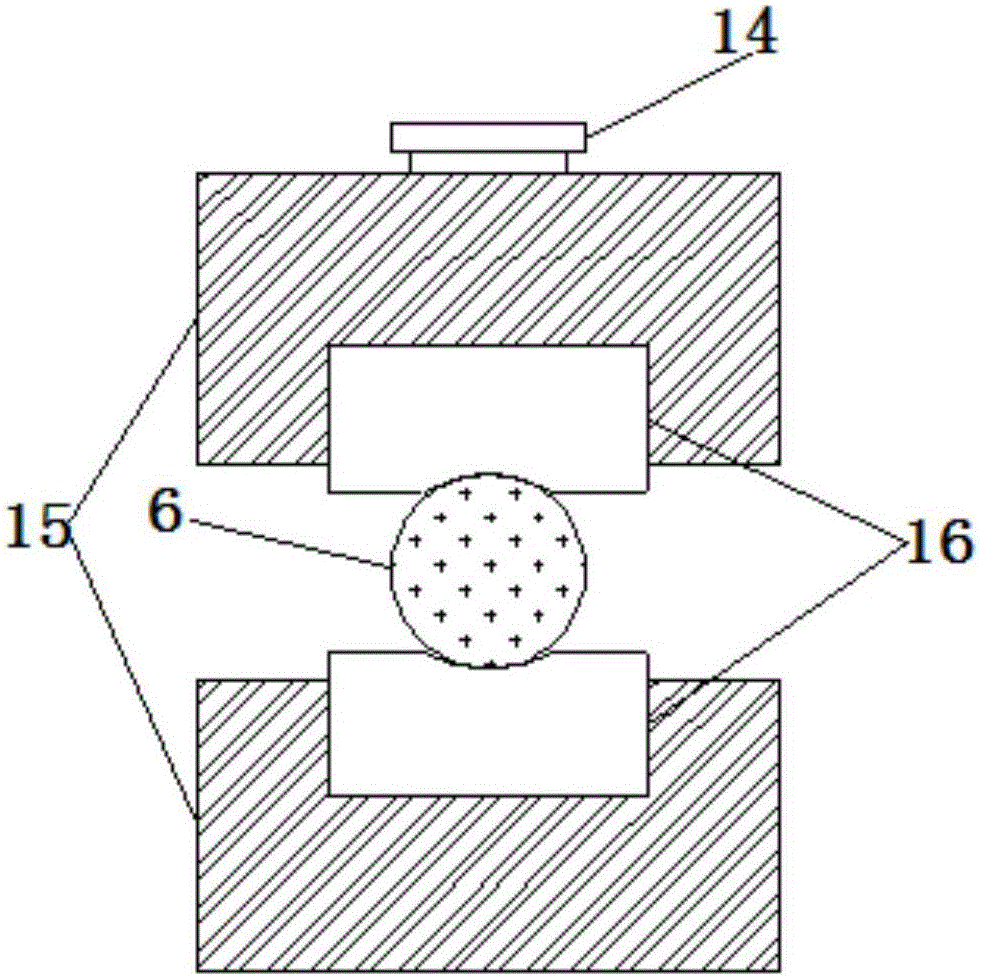

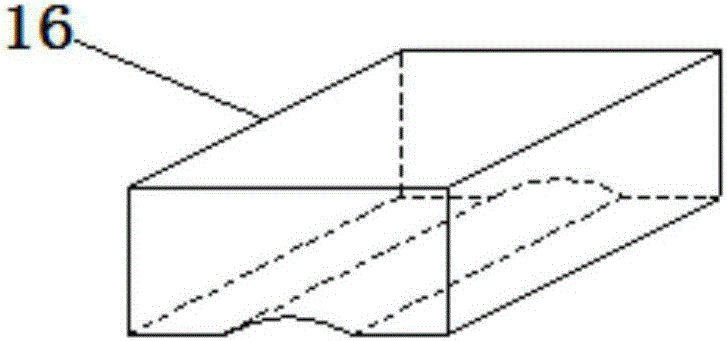

[0027] The structure of the rock fracture seepage parameter testing device provided in this embodiment is as follows: figure 1 As shown, at least including testing machine frame 4, testing machine triaxial cylinder 5 and indenter system are installed in described testing machine frame 4, and indenter system is made up of upper indenter 7 and lower indenter 11, is the sample of cylindrical shape 6 is placed between the upper pressing head 7 and the lower pressing head 11, its structure is as follows Figure 4 shown. The joints between the upper indenter, the lower indenter and the sample are sealed with latex film. The cracks of the sample are fixed with transparent glue to resist the confining pressure. The outer part of the sample is wrapped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com