Magnetic coupling feeding based circularly polarized antenna

A circularly polarized antenna and magnetic coupling technology, applied in the direction of antenna, electrical components, radiating element structure, etc., can solve the problem of increasing the size of the antenna, the difficulty of getting favored by the helical antenna, and the low polarization sensitivity of the target signal of the circularly polarized antenna. problem, to achieve the effect of excellent circular polarization performance and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in combination with specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

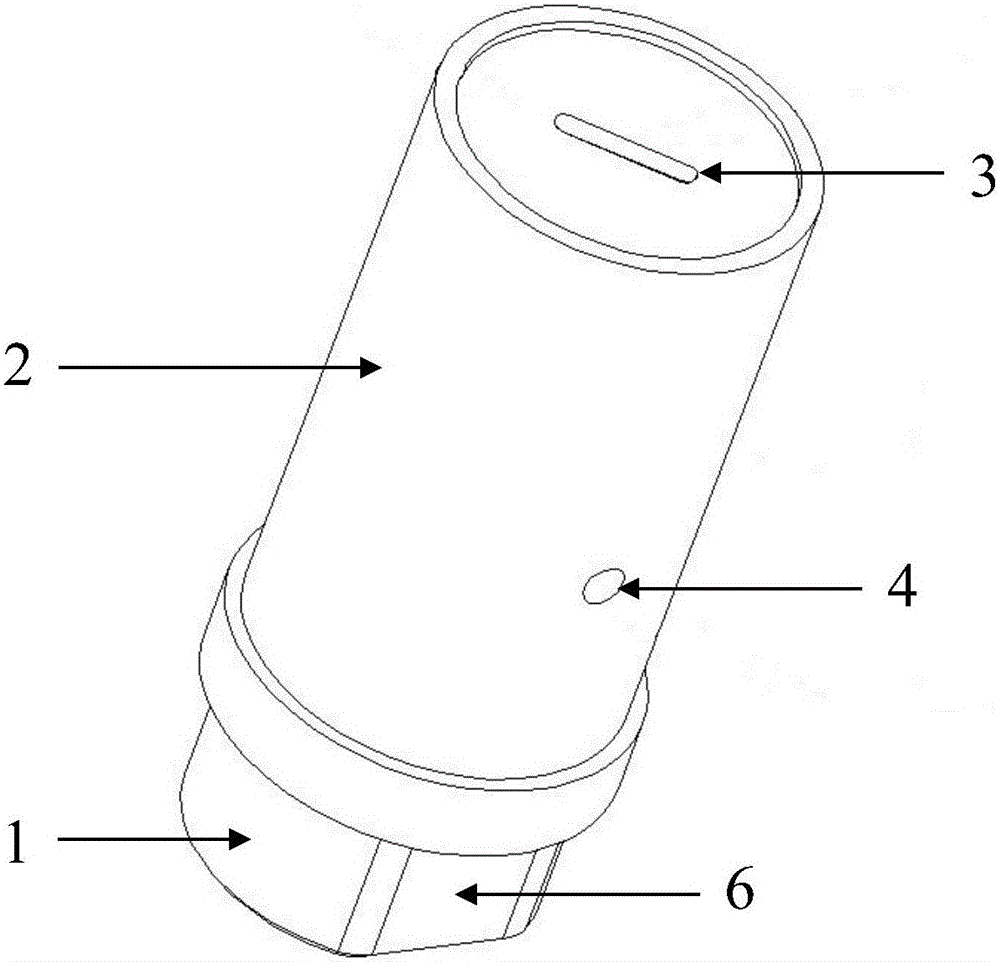

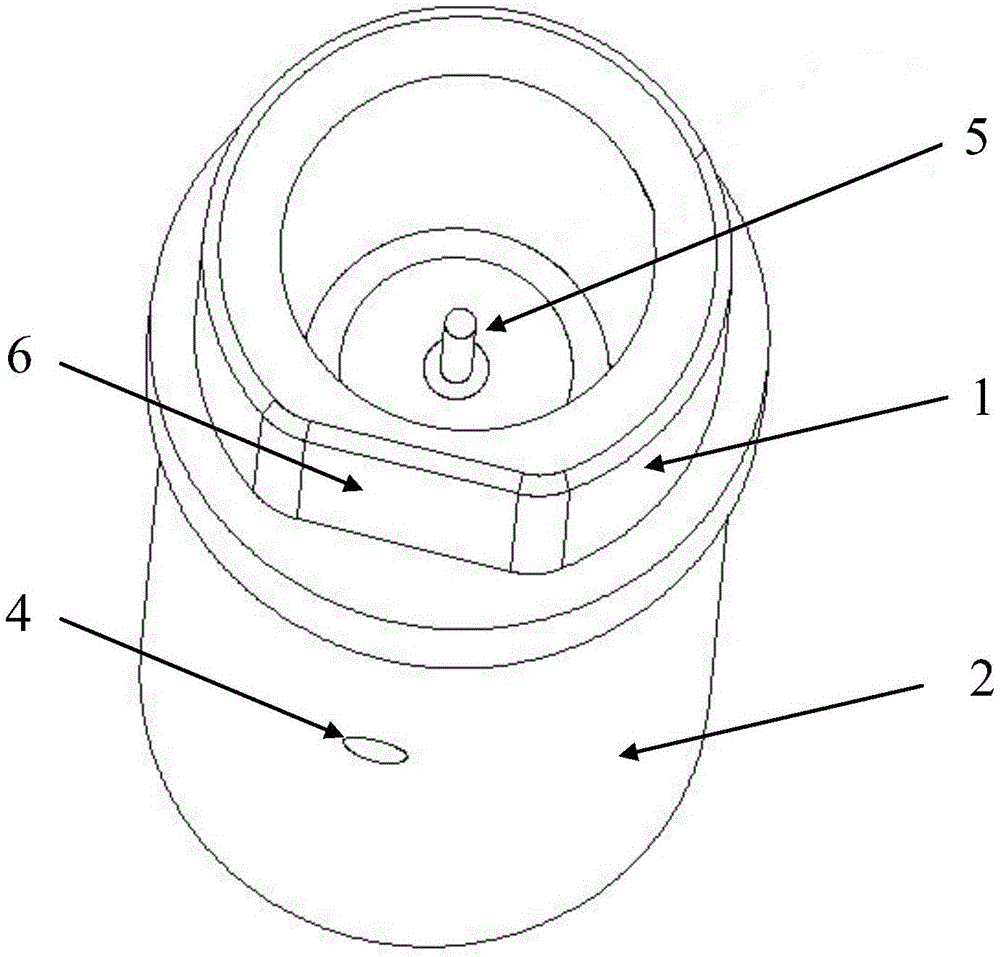

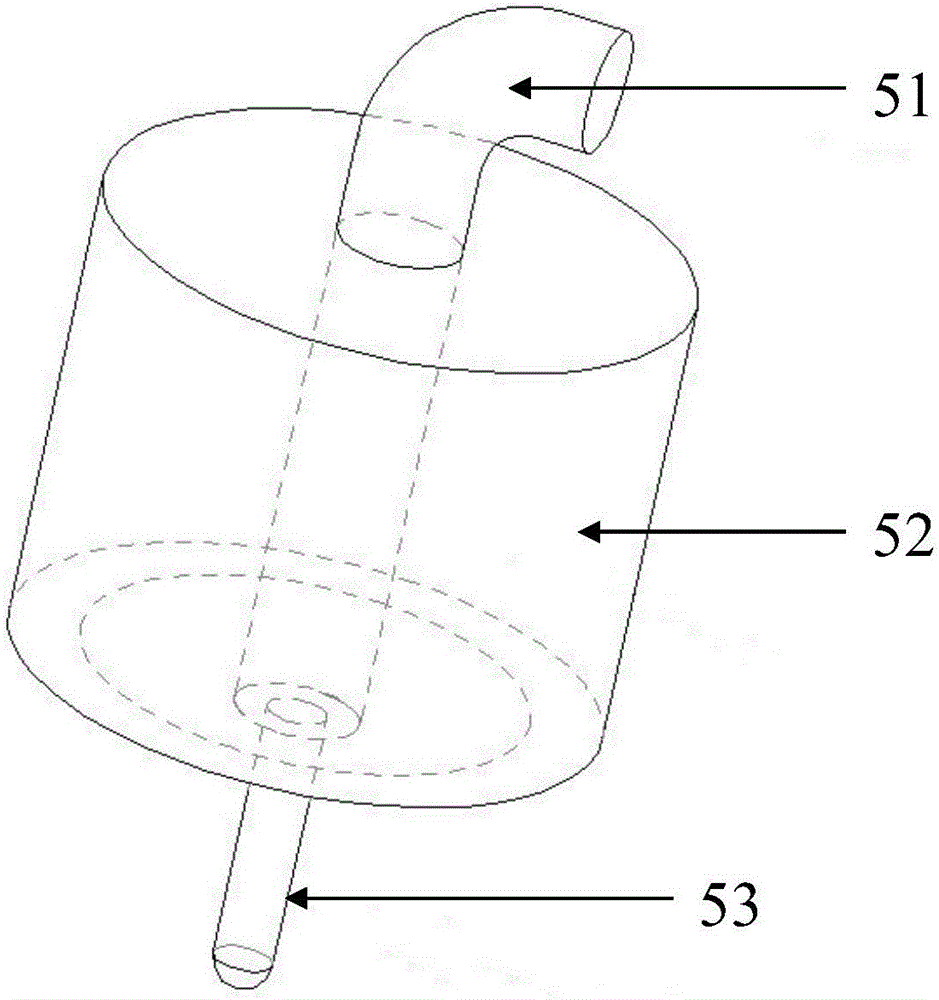

[0031] combine figure 1 , figure 2 , image 3 and Figure 4 The structural representations of the radiating end, feeding end, feeding part and antenna housing of the antenna of the present invention shown respectively; 5 and a polarized metal sheet 3, the feeding part 5 is set in the feed-in end 1 of the antenna case, and the polarized metal sheet 3 is set in the radiating end 2 of the antenna case.

[0032] Wherein, the radiation end 2 of the antenna housing has a rectangular waveguide cavity 22 and a circular waveguide cavity 21 , and the polarized metal sheet 3 is located on the axis of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com