Casing with automatic opening and closing water-cooling system

A water-cooling system, automatic opening and closing technology, applied in the direction of casing/cover/support, electromechanical device, electric component, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

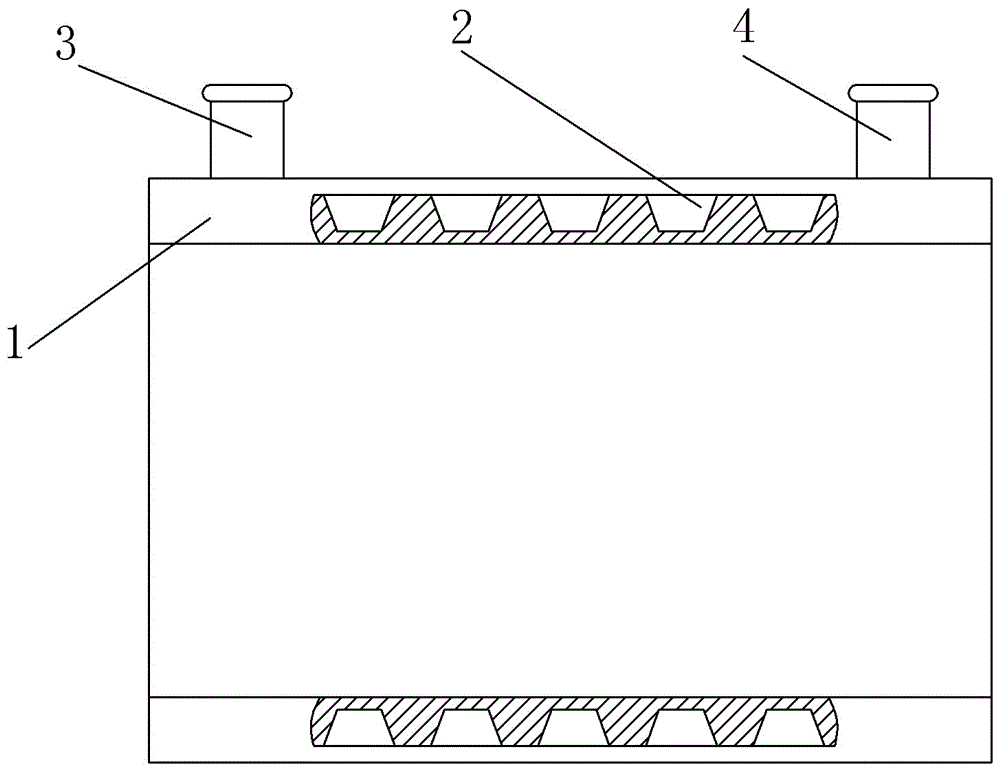

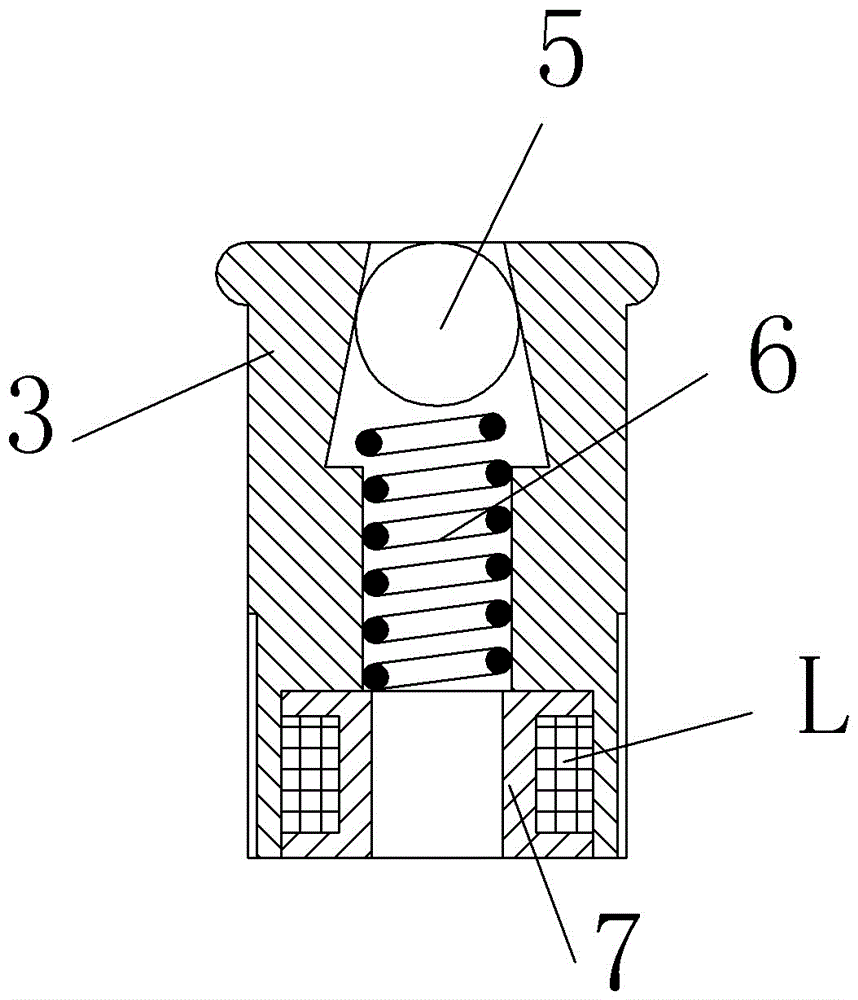

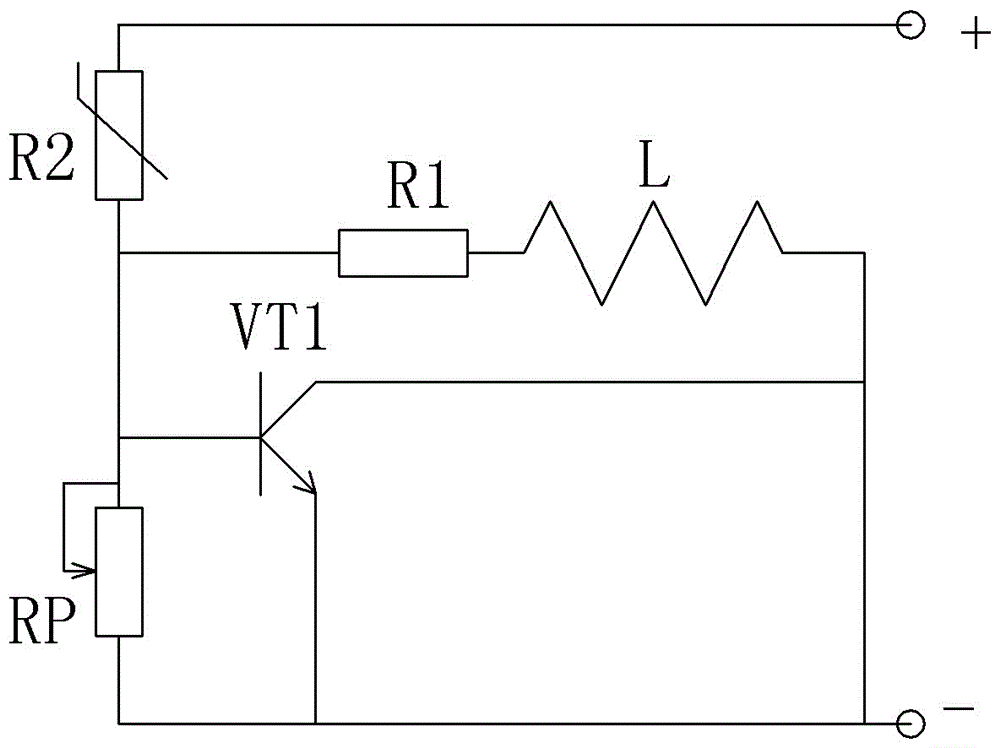

[0022] The reference signs in the accompanying drawings of the specification include: casing body 1, spiral water channel 2, water inlet pipe 3, water outlet pipe 4, steel ball 5, compression spring 6, electromagnetic block 7, DC excitation coil L, current limiting resistor R1, negative Temperature coefficient thermistor R2, adjustable resistor RP, triode VT1.

[0023] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a casing with an automatic opening and closing water cooling system, including a casing body 1, and a spiral water channel 2 is opened on the casing body 1, and the spiral water channel 2 is a spiral water channel 2 with a tapered structure, wherein the spiral water channel 2 has a tapered structure The big end is close to the outer wall of the casing body 1, and the small end of the tapered structure of the spiral water channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com