Method and apparatus for controlling operation velocity of linear servo system of high-precision numerical control machine tool

A technology for controlling linear and CNC machine tools, which is applied in the direction of control systems, vector control systems, and control of electromechanical transmission devices. Effects of coordinate transformation and chattering reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

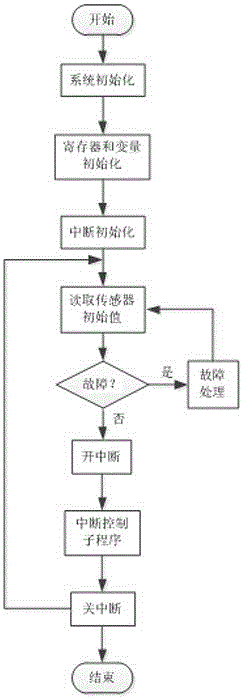

[0046] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

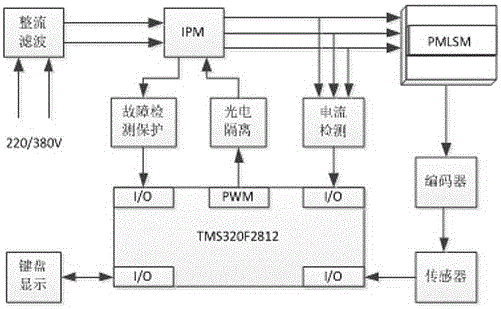

[0047] like figure 1 As shown, the present invention is applied to a control device for the running speed of a linear servo system of a high-precision numerical control machine tool, which includes: a rectification filter module, an IPM intelligent power module, a linear motor (PMLSM), a DSP digital signal processor unit, an A / D module (not marked in the figure), fault detection and protection module, photoelectric isolation module, current detection module, encoder, sensor, keyboard display.

[0048] The rectifier and filter module is connected to the IPM intelligent power module, and the IPM intelligent power module is connected to the linear motor (PMLSM). On the other hand, the current detection module collects the phase current output by the IPM intelligent power module, and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com