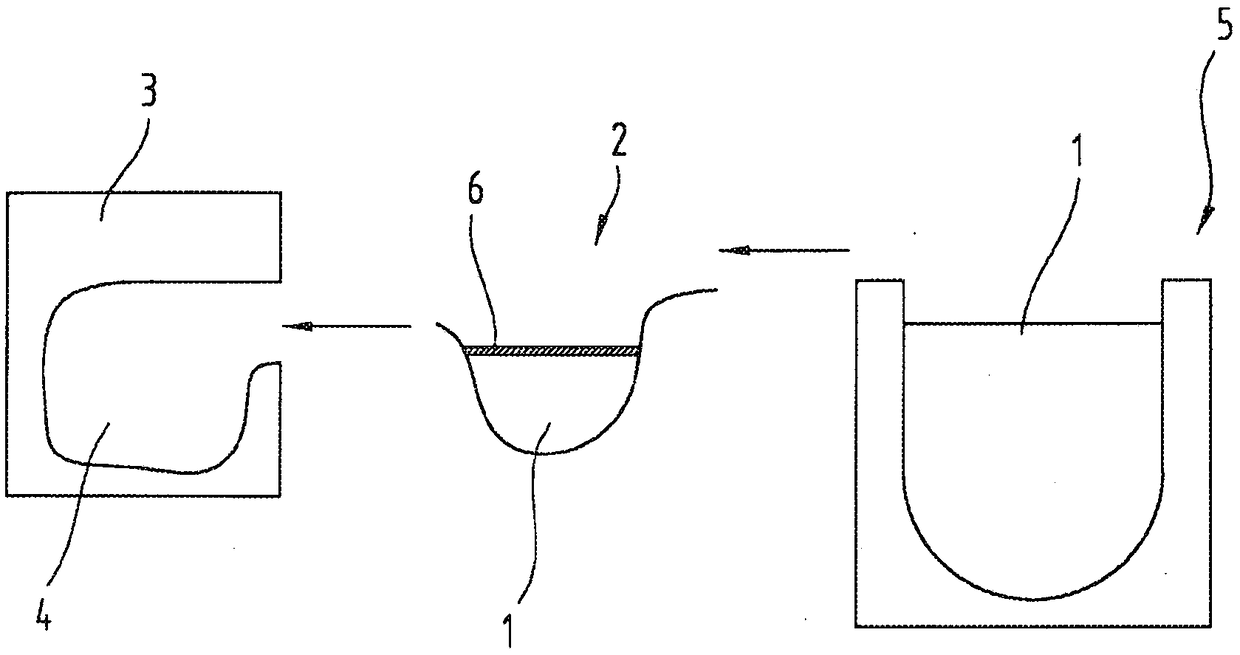

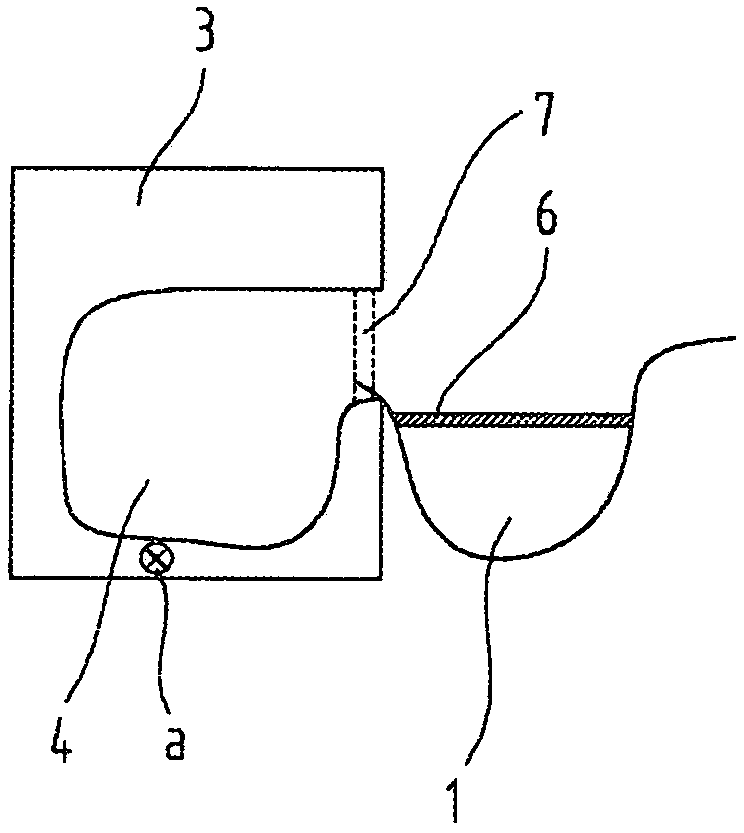

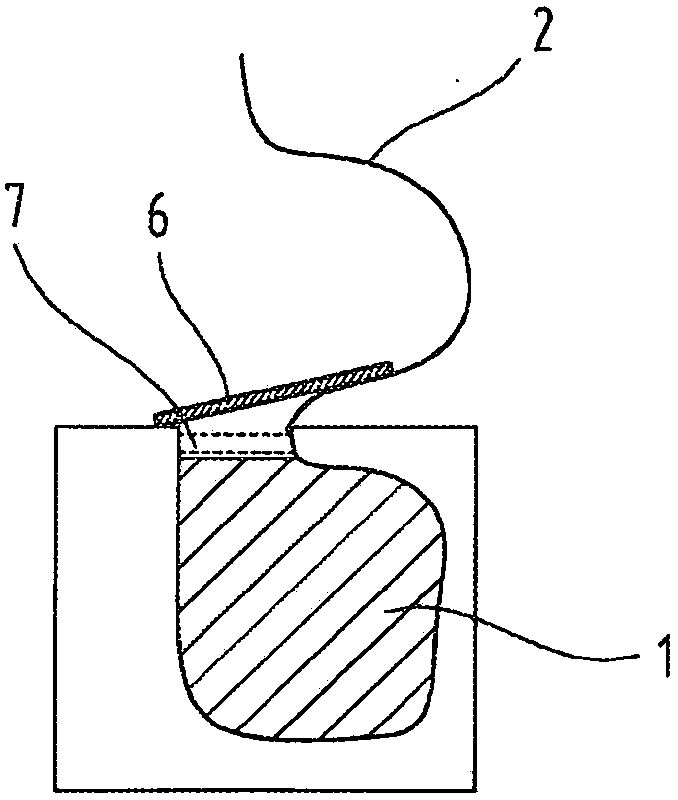

method for pouring castings

一种铸件、铸模的技术,应用在搬运铸型的设备、铸造车间、铸造设备等方向,能够解决损害铸件组织结构等问题,达到避免不均匀性、高质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As an introduction, it should first be explained that in the various embodiments described differently, the same components are provided with the same reference numerals or the same component names, and the disclosure content contained in the entire description can be transferred to the design according to the meaning. On the same part with the same reference number or the same component name. Furthermore, the orientation descriptions selected in the specification, such as up, down, sideways, etc., are relative to the direct description and the accompanying drawings, and these orientation descriptions can be transferred to the new direction according to the meaning when the orientation changes. orientation.

[0035] The exemplary embodiments show possible implementation variants of the solution according to the invention, and it should be pointed out here that the invention is not restricted to the specifically illustrated implementation variants of the invention, but r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com