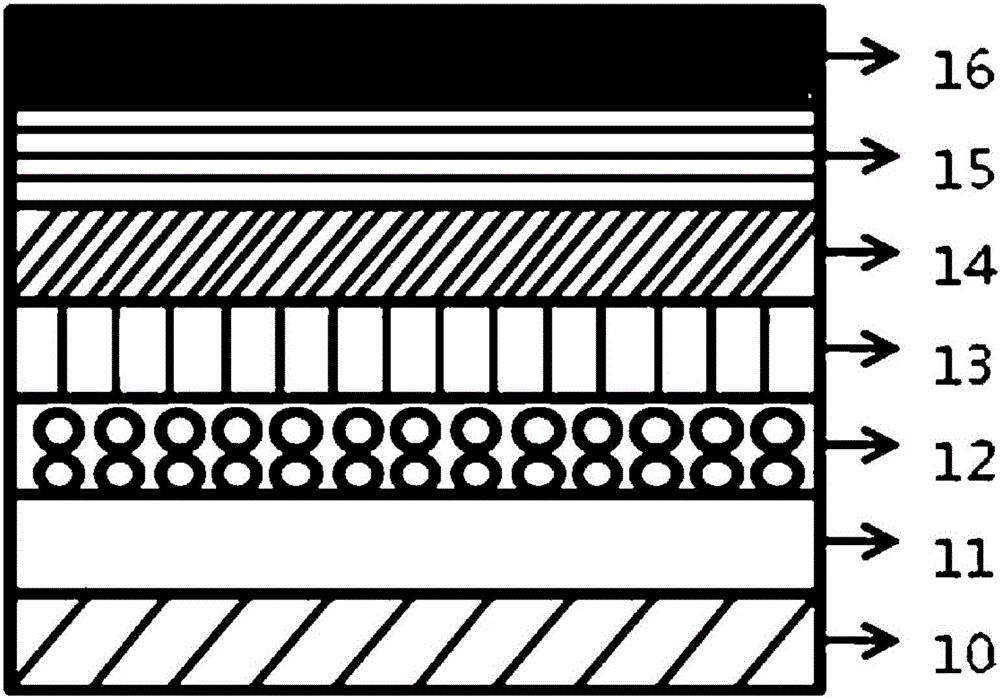

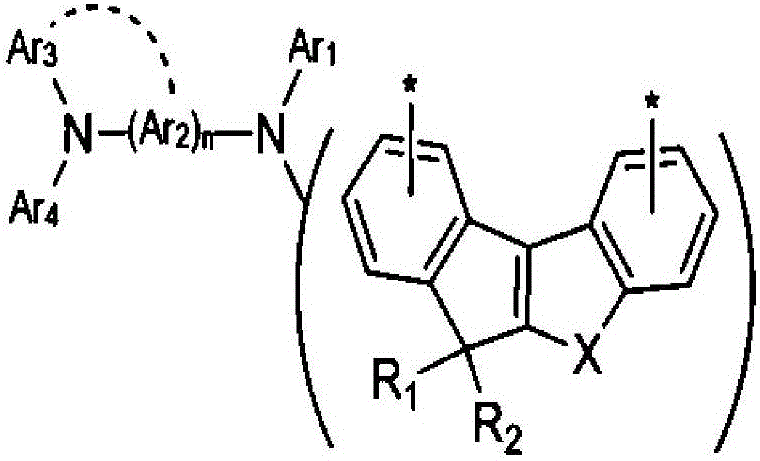

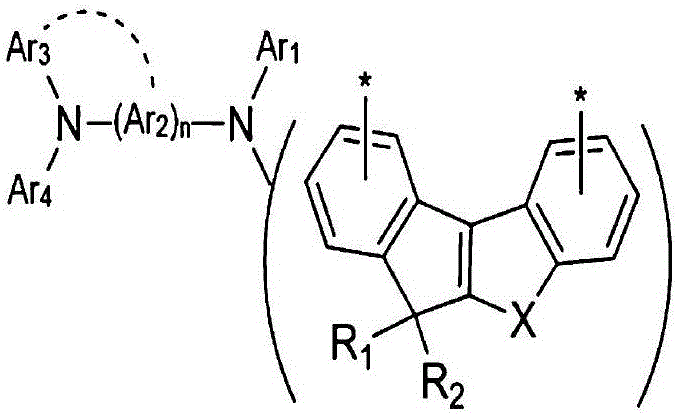

Novel hole injection and hole transport compound and organic light-emitting element comprising same

A technology of hole transport and hole injection, which is applied in the direction of household components, electrical components, luminescent materials, etc., can solve the problems of low efficiency, high driving voltage, short life, etc., and achieve excellent hole transport characteristics, high efficiency, excellent The effect of low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] Embodiment 1: the synthesis of compound 1

[0165]

[0166]

[0167] 20.0g of 4-bromo-N,N-diphenylaniline, 20.36g of bis(pinacolate) diboron, 0.2g of Pd(dppf)Cl 2 18.1 g of KOAc was dissolved in 400 ml of toluene, and stirred under reflux. The reaction was confirmed by TLC, and water was added, and then the reaction was terminated. The organic layer was extracted with EA, filtered under reduced pressure, and purified on a column to obtain 19.5 g of intermediate OP1 (yield 85%).

[0168] In a round bottom flask, 4.0 g of the above intermediate 1A-1, 3.7 g of OP1 were dissolved in 70 ml of toluene, and 12 ml of K 2 CO 3 (2M) and 0.3g of Pd(PPh 3 ) 4 , and then reflux stirring. The reaction was confirmed by TLC, and water was added, and then the reaction was terminated. The organic layer was extracted with EA, filtered under reduced pressure, and purified on a column to obtain 2.0 g of compound 1 (yield 72%).

[0169] m / z: 644.28 (100.0%), 645.29 (51.3%), 646...

Embodiment 2

[0170] Embodiment 2: the synthesis of compound 2

[0171]

[0172] Compound 2 was synthesized by the same method as Compound 1 except that Intermediate 2A-1 was used instead of Intermediate 1A-1 (yield 64%).

[0173] m / z: 694.30 (100.0%), 695.30 (56.4%), 696.31 (15.2%), 697.31 (2.8%)

Embodiment 3

[0174] Embodiment 3: the synthesis of compound 3

[0175]

[0176] Using N-(4-bromophenyl)-N-phenylnaphthalene-1-amine instead of 4-bromo-N,N-diphenylaniline for the reaction, synthesized by the same method as OP1 OP2 (60% yield).

[0177] Compound 3 was synthesized by the same method as Compound 1 except that Intermediate 2A-1 and OP2 were reacted (yield 68%).

[0178] m / z: 744.31 (100.0%), 745.32 (60.0%), 746.32 (17.9%), 747.32 (3.6%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com