Engine block of a diesel engine with integrated cylinder head, and casting method

一种发动机缸体、柴油发动机的技术,应用在机的发动机缸体领域,能够解决损毁、耗费时间、构型受限等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

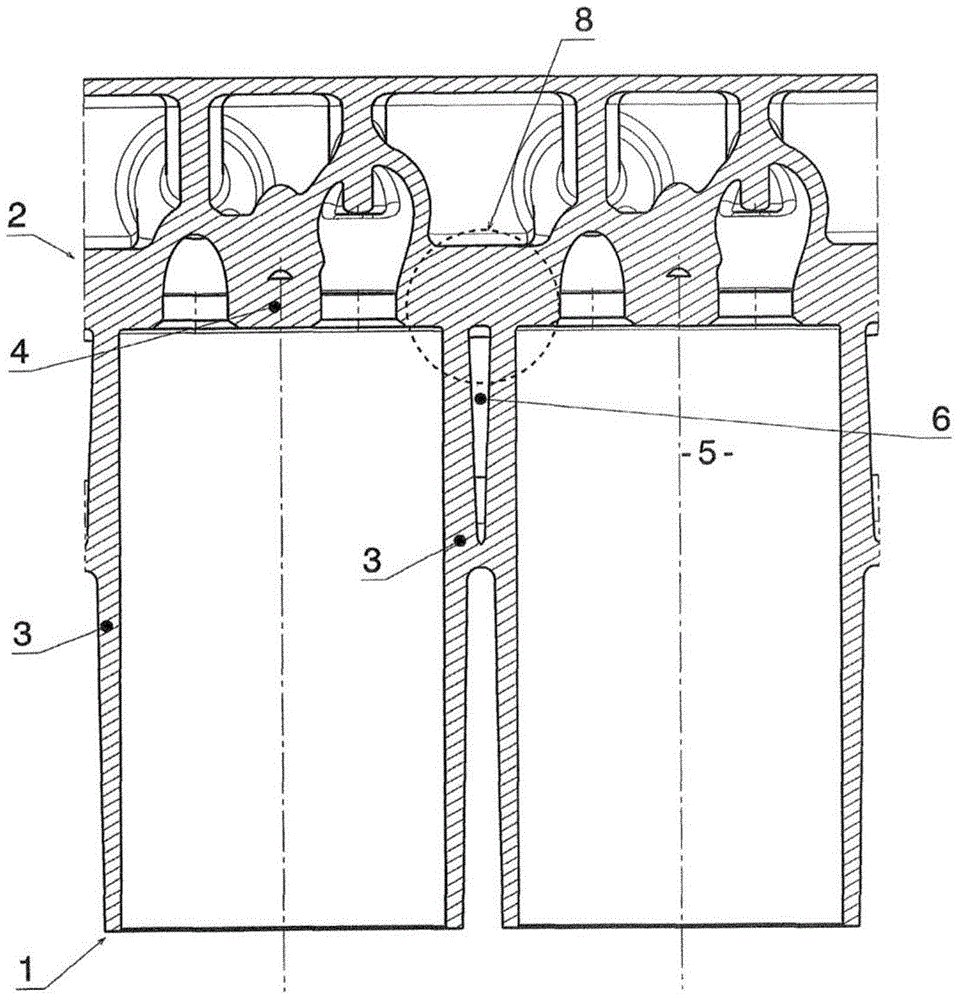

[0025] Referring to Fig. 1, the problem to be solved by the present invention is first described according to the prior art. An engine block 1 with in-line cylinders is integrally cast with a cover portion 2 . The cylinder wall 3 surrounds the combustion chamber 5 and is completely surrounded on all sides by cooling chambers which are circulated by a cooling fluid, usually water. In the casting mold, the cooling chamber is realized by the sand core. They are formed in specific moulds. In order to enable the core to be pulled out from the mold intact, a certain angle of forging slope is required, and the thinner (more brittle) the core, the larger the angle of the forging slope. The cores are especially thinner in the gap 6 between the cylinder walls 3 of adjacent cylinders. Due to the swaging inclination, the thickness of the gap 6 increases continuously from bottom to top up to the cylinder head 4 and the thickness of the cylinder wall 3 decreases continuously. As a resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com