Coordination deformation support system suitable for soft-rock large-deformation tunnel, and support method of support system

A large deformation and tunnel technology, applied in the coordinated deformation support system and its support field, can solve the problems of limited deformation capacity, increased engineering cost, initial support rupture, etc., to reduce requirements, save engineering cost, and have good integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

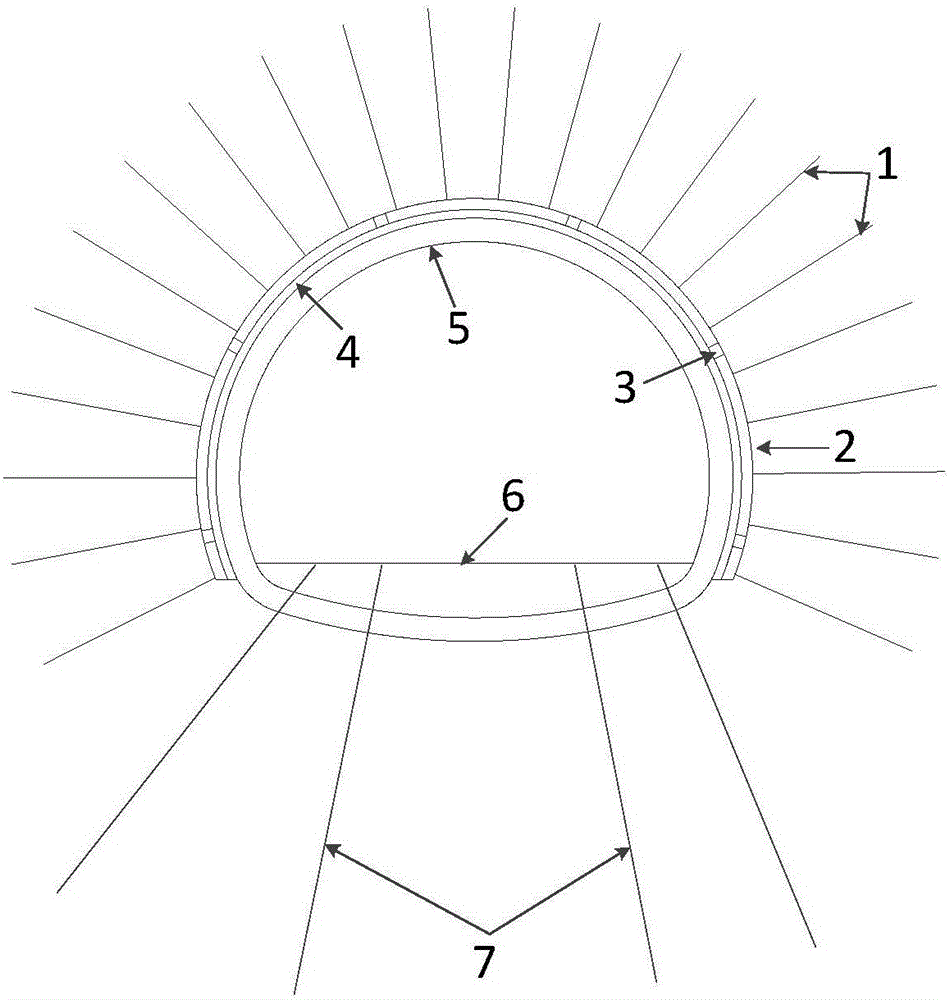

[0044] A support system suitable for soft rock tunnels such as figure 1 As shown, it includes an anchor rod 1, a primary lining (that is, the first protective layer) composed of a concrete sprayed layer 2 and a compressible pad 3, a foam concrete filling layer 4, a secondary lining 5 and an inverted arch 6.

[0045] Wherein, the bolt 1 goes deep into the stable rock mass, the first protective layer is closely attached to the inner wall of the surrounding rock, the inner side of the first protective layer is provided with a foamed concrete filling layer 4, and the inner side of the foamed concrete filled layer 4 is provided with a secondary lining 5.

[0046]The foam concrete filling layer 4 can absorb the long-term deformation of the surrounding rock, reduce the deformation pressure of the secondary lining caused by the long-term deformation of the surrounding rock, and ensure the long-term stability of the secondary lining. The foamed concrete filling layer 4 and the first pr...

Embodiment 2

[0067] The formula of the thickener added in the foam concrete is: silica fume: 60 parts; bentonite: 70 parts; xanthan gum: 1 part. Pour into a container and stir until smooth. When the thickener is in use, the weight of the thickener accounts for 8% of the weight of the cement in the foam concrete.

Embodiment 3

[0069] The formula of the thickener added in the foam concrete is: silica fume: 100 parts; bentonite: 40 parts; polyacrylamide: 0.3 parts. Pour into a container and stir until smooth. When the thickener is in use, it is added according to the weight of the thickener accounting for 10% of the weight of the cement in the foam concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com