Pre-shaping device before printing of wood-grained paper, and pre-shaping method thereof

A wood-grain paper, pre-shaped technology, used in printing, printing presses, general parts of printing machinery, etc., can solve the problem of reduced slip and stress dispersion, reduced paper flexibility and folding endurance, moisture content wood grain The problem of large impact on paper can achieve the same shrinkage ratio, reduce joint waste, and facilitate subsequent printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

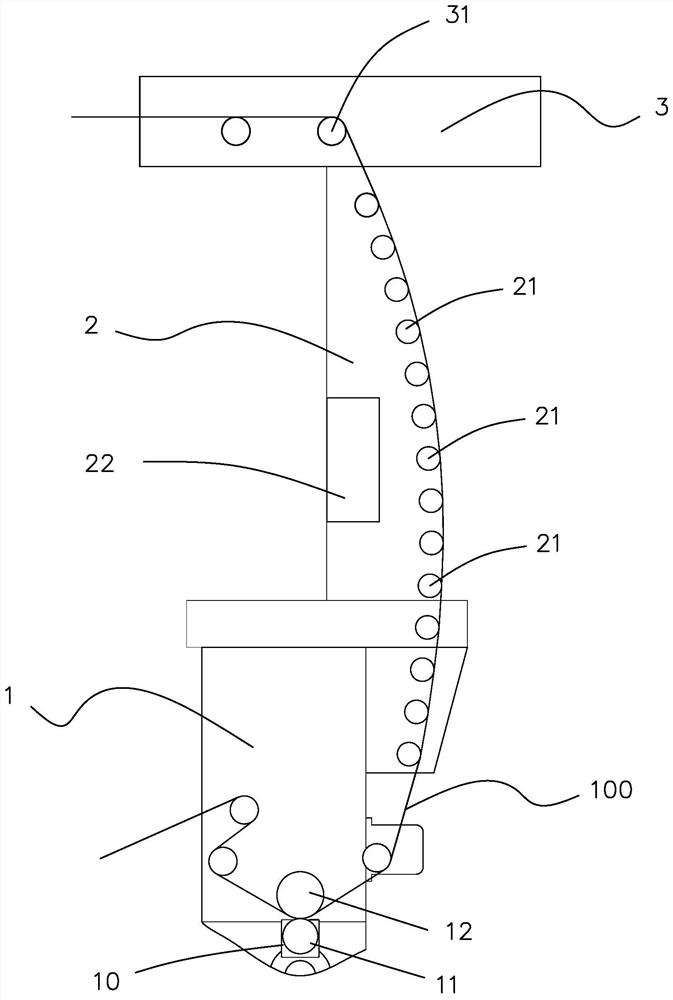

[0025] A paper pre-printing device for wood-grain paper, including a printing wallboard 1 for increasing the moisture content of the wood-grain paper and a bellows wallboard 2 for drying the wood-grain paper after the moisture content is increased, and the printing wallboard The bottom of the board 1 is provided with a water tank 10 for storing water, and the water tank 10 is provided with an embossing steel roller 11 for transferring water to the wood grain paper. The embossing rubber roller 12 on the steel roller 11, the bellows wallboard 2 are provided with several bellows guide rollers 21 for the wood grain paper to be conveyed and a drying machine for drying the wood grain paper conveyed on the bellows guide rollers 21. Component 22.

[0026] In order to quickly reduce the temperature of the dried wood grain paper, the above-mentioned pre-printing device for wood grain paper also includes a cooling wallboard 3, and the cooling wallboard 3 is provided with a device for coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com