Flexible anchor rod

An anchor rod and flexible technology, applied in the installation of anchor rods, mining equipment, earth-moving drilling, etc., can solve the problems of high cost, inability to tighten nuts, low compressive strength, etc., and achieve convenient installation and construction, small exposed length, and rod body. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

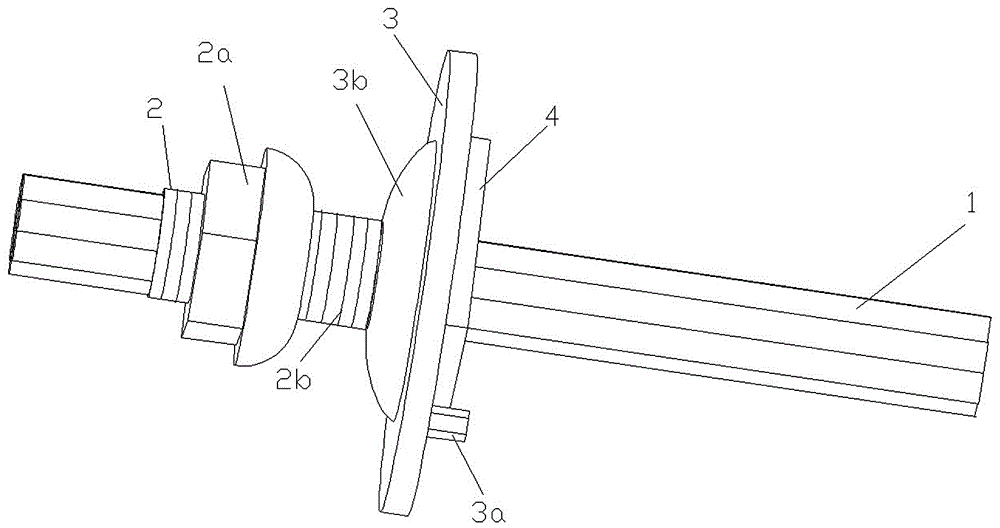

[0016] Such as figure 1 , 2 As shown, a flexible anchor rod is characterized in that: it includes a steel strand 1, on the steel strand 1, the sleeve 2 is fixed on the steel strand 1 by hydraulic pressing with an extrusion spring not shown in the figure. 1 on. The extruded spring is a steel cylindrical spring with a triangular cross-section.

[0017] Thread 2b is provided on the outer wall of the casing 2, and a spherical crown self-aligning nut 2a corresponding to the thread is sleeved on the casing 2, and a combination of ordinary nuts and spherical washers can also be used to replace the spherical crown self-aligning nut 2a .

[0018] A tray 3 is provided, and an upwardly protruding circular arch 3b is arranged on the tray 3. A through hole corresponding to the sleeve pipe 2 is provided at the center of the circular arch 3b. On the lower surface of the tray 3, there is also a vertical There is a columnar pin 3a.

[0019] The tray 3 is threaded on the steel strand 1 on ...

Embodiment 2

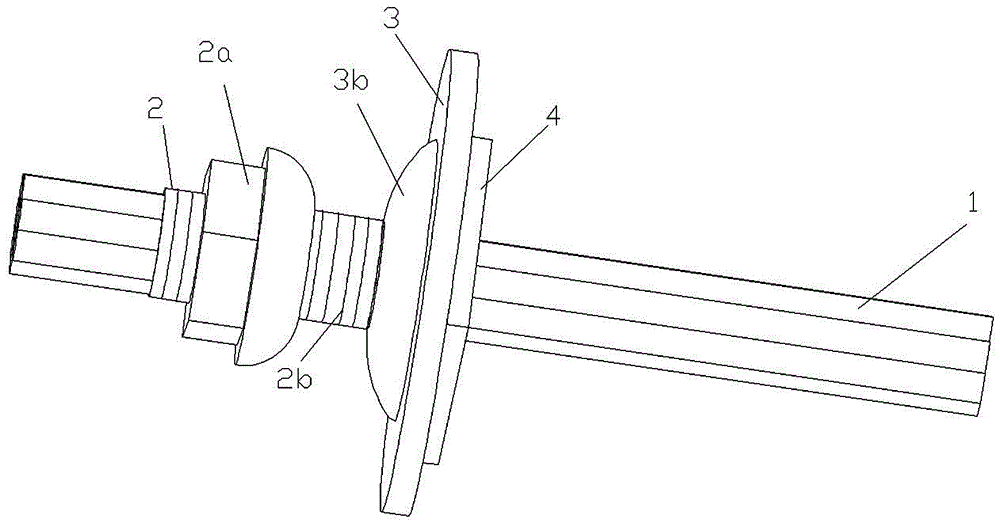

[0026] Such as figure 2 , 3 As shown, a flexible anchor rod is characterized in that: it includes a steel strand 1, on the steel strand 1, the sleeve 2 is fixed on the steel strand 1 by hydraulic pressing with an extrusion spring not shown in the figure. 1 on. The extruded spring is a steel cylindrical spring with a triangular cross-section.

[0027] Thread 2b is provided on the outer wall of the casing 2, and a spherical crown self-aligning nut 2a corresponding to the thread is sleeved on the casing 2, and a combination of ordinary nuts and spherical washers can also be used to replace the spherical crown self-aligning nut 2a .

[0028] A tray 3 is provided, and an upwardly protruding circular arch 3b is provided on the tray 3, and a through hole corresponding to the sleeve 2 is provided at the center of the circular arch 3b.

[0029] The tray 3 is threaded on the steel strand 1 on the spherical side of the spherical crown self-aligning nut 2a, so that the top end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com