Physical quantity sensor, manufacturing method thereof, electronic equipment, and movable body

A technology of a physical quantity sensor and a manufacturing method, which is applied in the direction of measuring instrument components, manufacturing microstructure devices, microelectronic microstructure devices, etc., and can solve problems such as inability to fully protect the cover part and the base body, peeling of the cover body, distortion of the base body and the cover body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, the embodiment described below is not an aspect which unduly limits the content of this invention described in a claim. In addition, not all the configurations described below are essential configuration requirements of the present invention.

[0057] 1. Physical quantity sensor

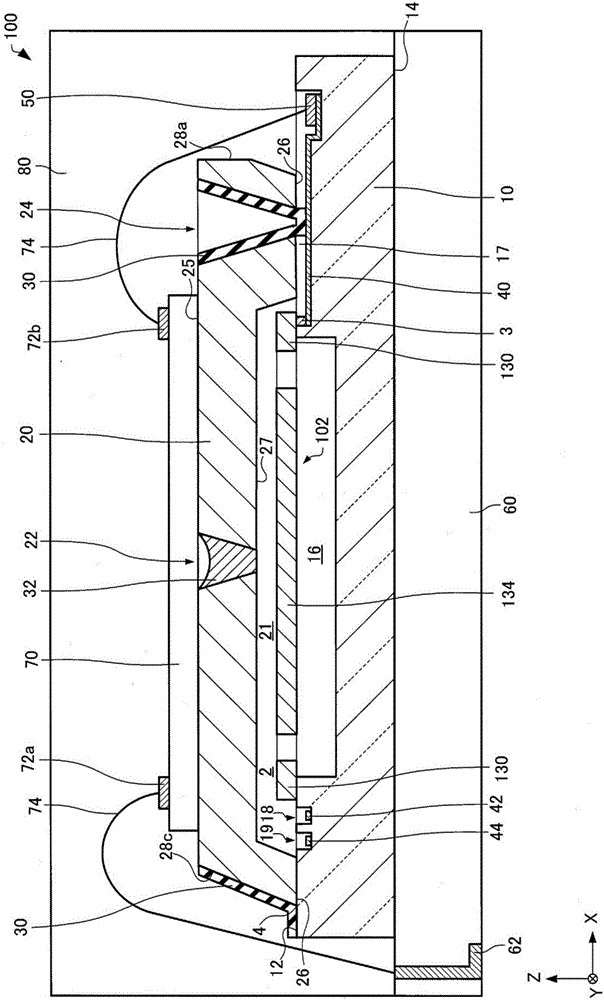

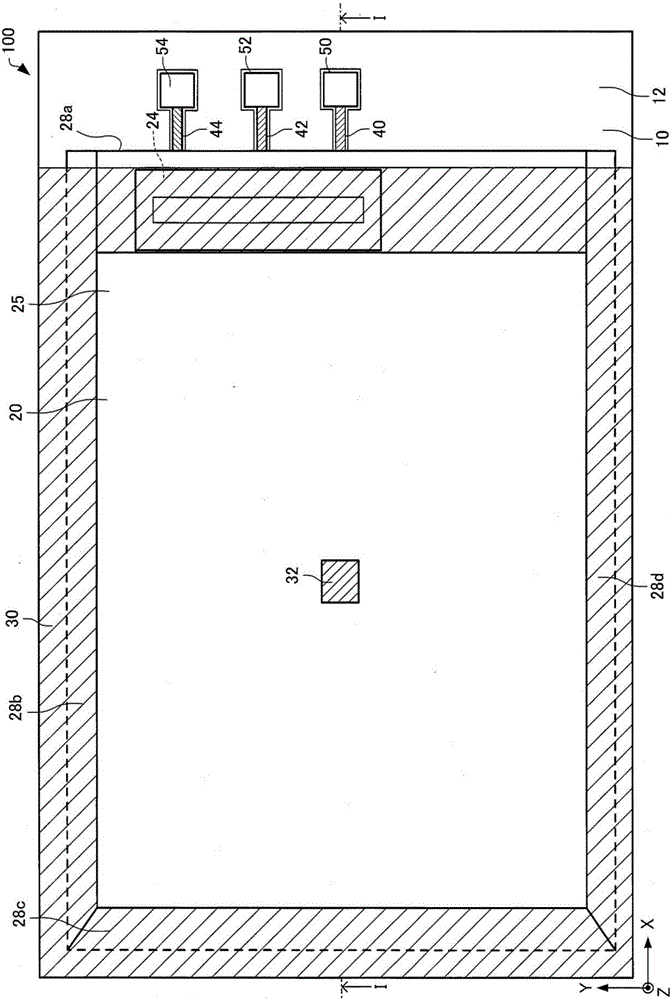

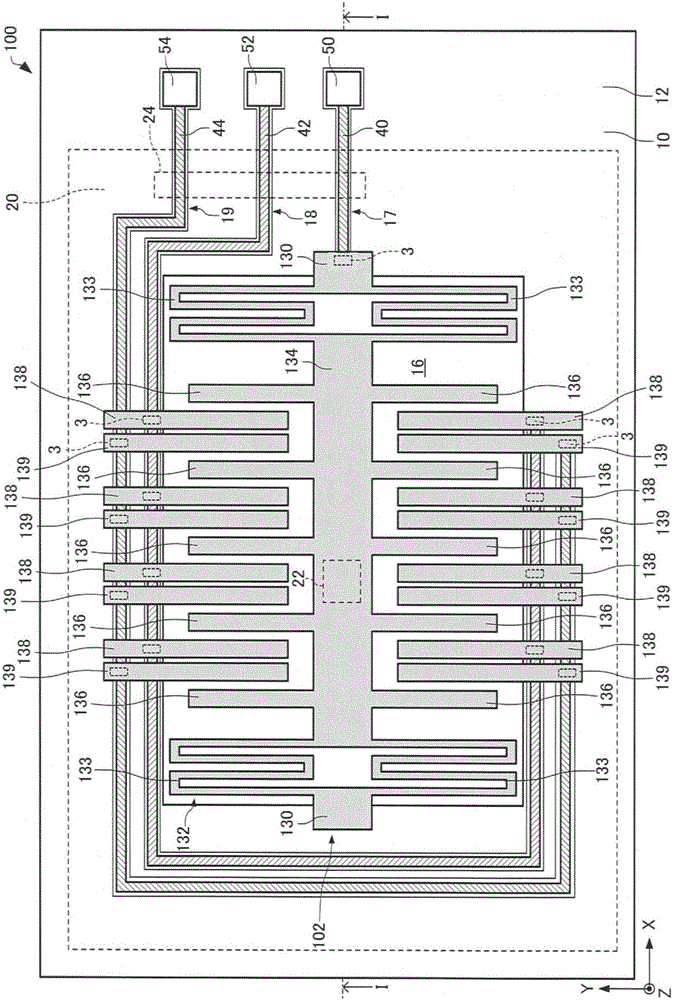

[0058] First, a physical quantity sensor according to the present embodiment will be described with reference to the drawings. figure 1 It is a cross-sectional view schematically showing the physical quantity sensor 100 according to this embodiment. figure 2 and image 3 It is a top view schematically showing the physical quantity sensor 100 according to this embodiment. in addition, figure 1 for figure 2 and image 3 Sectional view of the I-I line. In addition, in Figure 1 ~ Figure 3 In , the X axis, the Y axis, and the Z axis are shown as three mutual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com