LED drive device and control circuit and control method of LED drive device

A technology of LED drive and control circuit, applied in lighting devices, electric light sources, electrical components, etc., can solve the problems of high cost and complicated control, and achieve the effect of high power factor, good input voltage linearity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

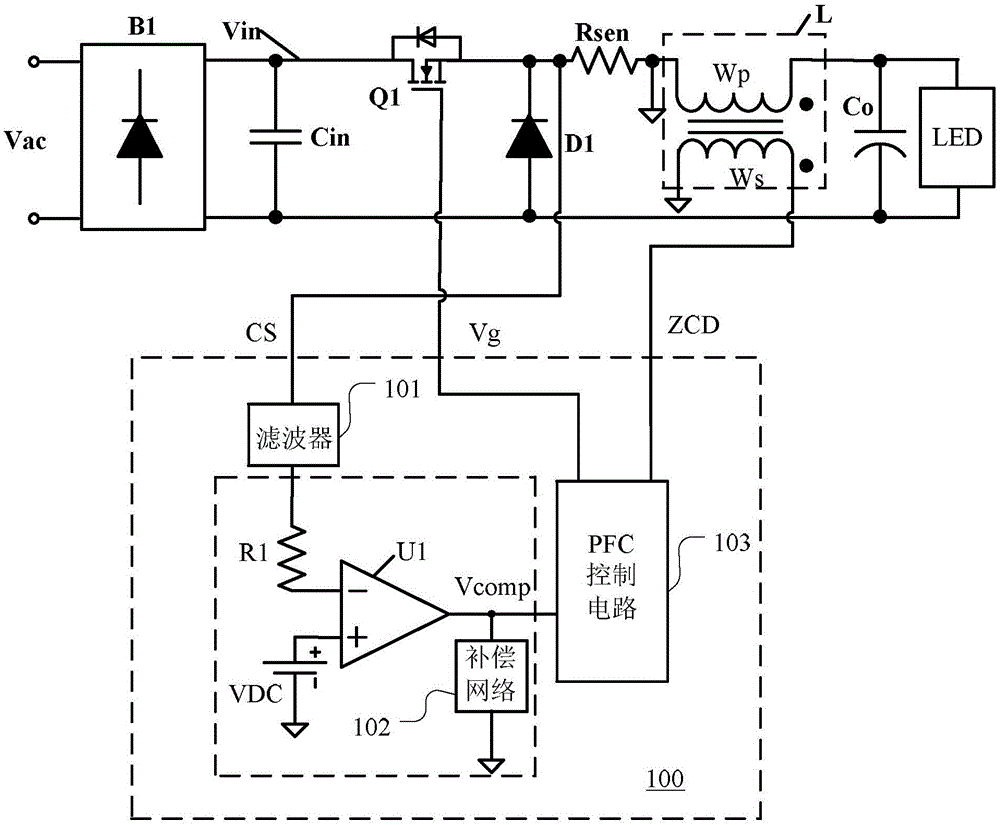

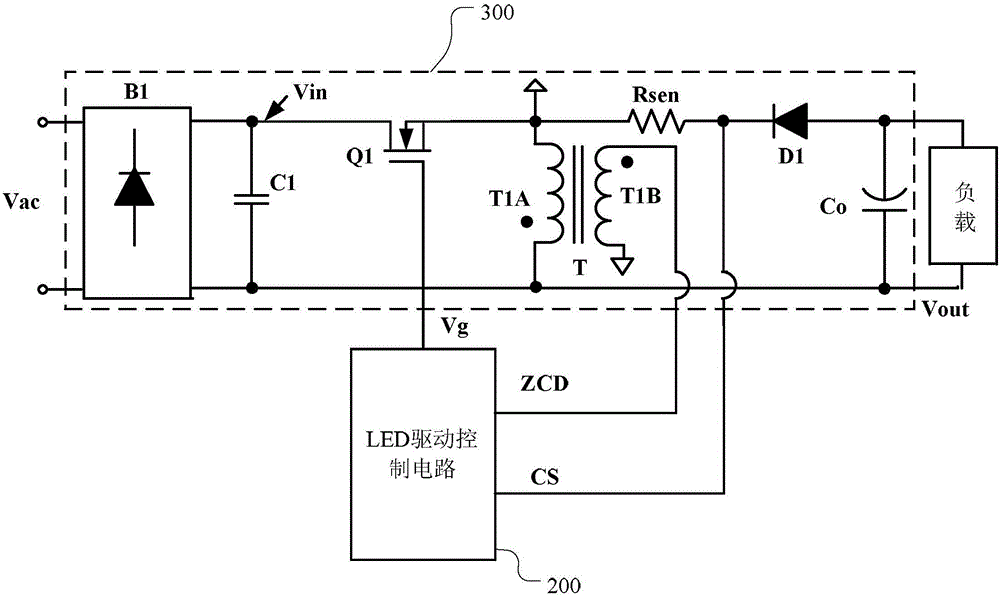

[0038] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

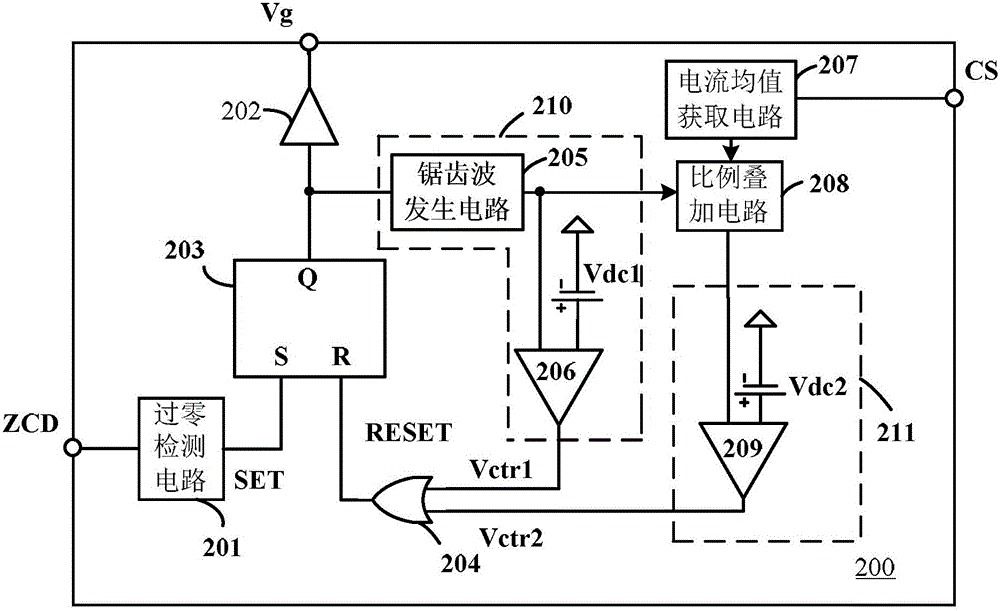

[0040] refer to figure 2 According to the embodiment of the present invention, the LED drive control circuit 200 includes a current average acquisition circuit 207, a proportional superposition circuit 208, a conduction time control circuit 210, a comparison circuit 211, an OR gate 204, an RS trigger circuit 203, a switch drive circuit 202, an overlay Zero detection circuit 201. The LED driving control circuit 200 may have a separate reference ground.

[0041] The on-time control circuit 210 includes a sawtooth wave generating circuit 205 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com