Spiral separation membrane element

一种分离膜、螺旋型的技术,应用在螺旋型分离膜元件领域,能够解决盐截留率降低、皮层易受到损伤等问题,达到盐截留率降低、耐氧化剂性优异、省略或简化预处理的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] An amine solution was prepared by dissolving 3% by weight of N,N'-dimethyl-m-phenylenediamine, 0.15% by weight of sodium lauryl sulfate, 2.5% by weight of triethylamine, and 5% by weight of camphorsulfonic acid in ethylene glycol. . In addition, 0.2% by weight of trimesoyl chloride and 0.4% by weight of isophthaloyl chloride were dissolved in Exxsol D30 (manufactured by Exxon Mobil, distillation range 130 to 160°C, boiling point 148°C) to prepare an acid chloride solution. And, the amine solution covering layer is formed by applying the amine solution on the porous support and removing excess amine solution. Next, an acid chloride solution is applied to the surface of the amine solution coating layer. Afterwards, the excess solution was removed, and further kept in a hot air dryer at 100° C. for 5 minutes to form a skin layer containing a polyamide-based resin on the porous support, thereby producing a composite semipermeable membrane.

[0063] Using the detection uni...

Embodiment 2~7、 comparative example 1 and 2

[0066] Except using the composite semipermeable membrane produced in Example 1, and using the permeation-side channel material of the warp-knitted fabric having the porosity described in Table 1, the permeation flux and Salt rejection.

[0067] Reference example 1~3

[0068] A composite semipermeable membrane was produced in the same manner as in Example 1, except that 3% by weight of m-phenylenediamine was used instead of 3% by weight of N,N'-dimethyl-m-phenylenediamine in Example 1. In addition, the permeation flux and salt rejection were measured in the same manner as in Example 1, except that the prepared composite semipermeable membrane was used as the permeation-side channel material of the warp-knitted fabric having the porosity described in Table 1. Rate.

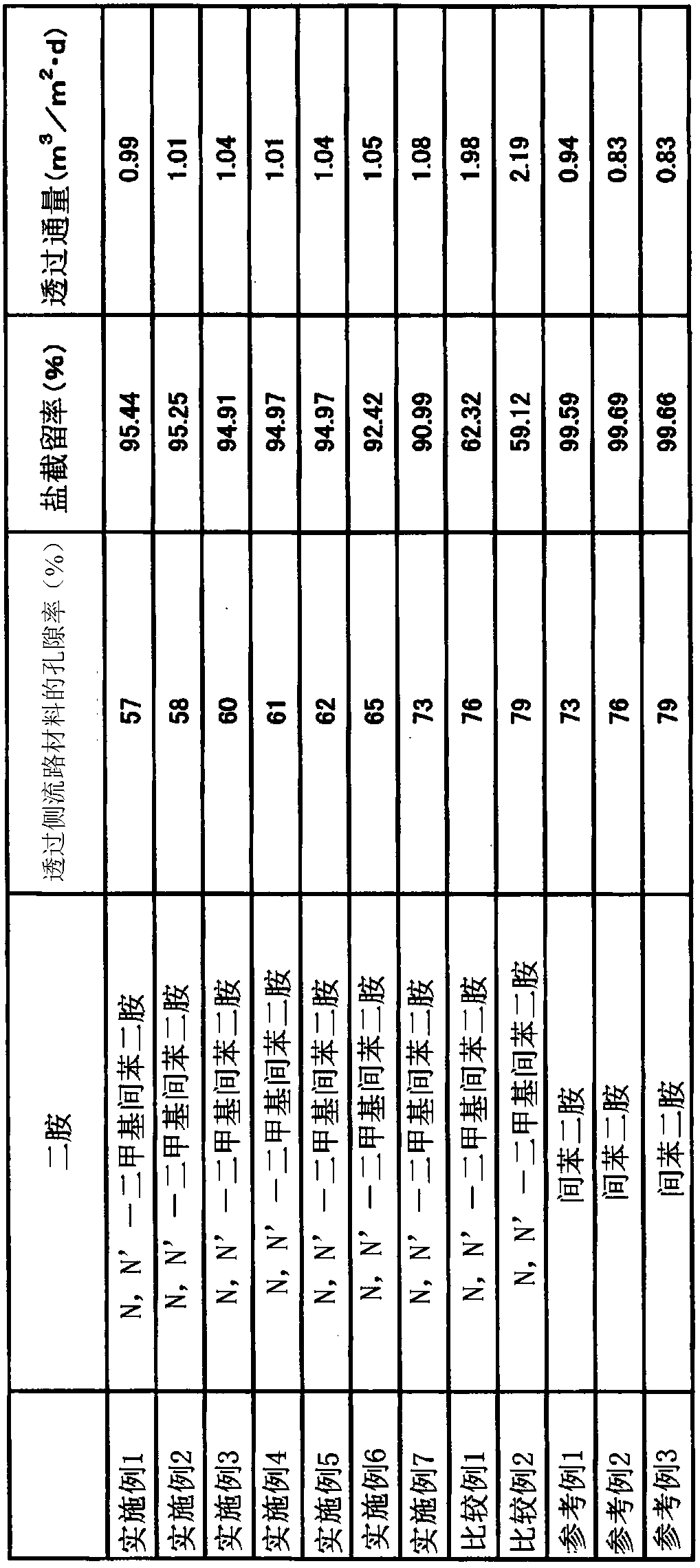

[0069] [Table 1]

[0070]

[0071] As can be seen from Table 1, the composite semipermeable membranes of Examples 1 to 7 prepared using N,N'-dimethyl-m-phenylenediamine as the polyfunctional amine component ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com