High efficiency soya-bean milk making method

A production method and technology for soybean milk, which are applied to dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of affecting the production cycle of soybean milk, small heating power, and slow heating process of soybean milk machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

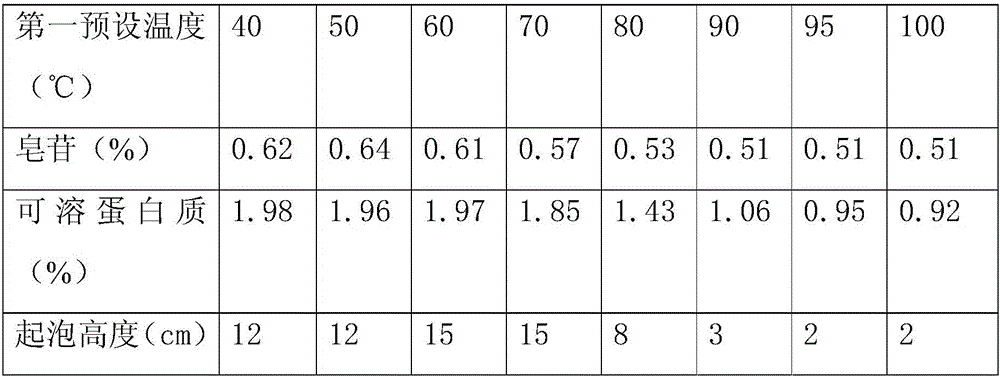

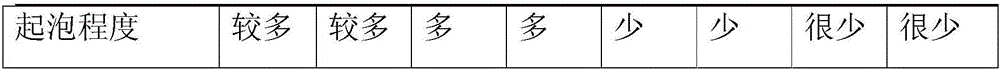

[0017] A high-efficiency soybean milk production method, which provides a motor, a crushing tool, a heating device, an anti-overflow electrode, a control unit, and a cup body. The control unit is electrically connected to the motor, the heating device, and the anti-overflow electrode, and at least includes the following stages:

[0018] (1) Preheating stage: the heating device heats the water and materials in the cup, and when the temperature of the liquid is lower than the first preset temperature, the control unit ignores the overflow signal detected by the anti-overflow electrode;

[0019] (2) Pulverizing stage: the motor drives the pulverizing cutter to rotate and pulverize water and materials to slurry, and enter the next stage;

[0020] (3) Boiling stage: the heating device heats the slurry until it is cooked.

[0021] In this embodiment, in the preheating stage, the heating device heats the water and materials in the cup to the first preset temperature and directly ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com