A kind of beneficiation desilicon enrichment method of fine-grained hematite

A hematite and fine-grained technology, which is applied in the field of mineral processing engineering, can solve the problems of small magnetic susceptibility of fine-grained hematite, inability to obtain high-quality iron concentrate, complex process of iron concentrate, etc., to simplify the centrifugal classification process , reduce the cost of beneficiation, and reduce the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

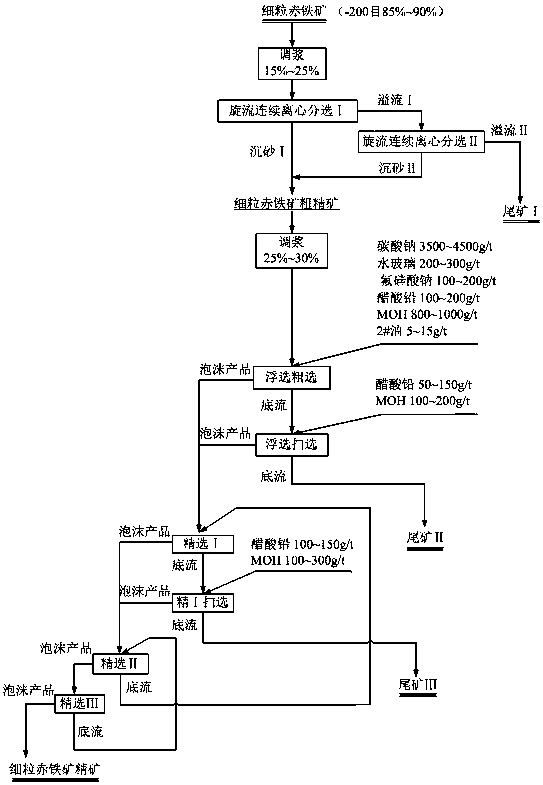

Embodiment 1

[0020] Hematite in Simao area, Yunnan Province contains 36.41% Fe, SiO 2 39.76%, the main metal minerals are hematite, with a small amount of limonite, and the gangue minerals are mainly quartz, sericite, calcite, kaolinite, etc. After the hematite is crushed and screened, the ore is ground to -200 mesh, accounting for 85%, water is added to adjust the slurry concentration to 15%, and the cyclone continuous centrifugal separator is used for two graded desliming operations, and the overflow is used as the tailings I desliming operation. Remove; Slurry the grit obtained after the double classification of the cyclone continuous centrifugal separator, adjust the concentration to 25%; add sodium carbonate 3500g / t, water glass 300g / t, sodium fluorosilicate 200g / t, Lead acetate 100g / t, MOH900g / t, 2 # Oil 5g / t, after fully sizing, carry out flotation roughing; add lead acetate 100g / t, MOH 100g / t to the underflow after roughing, sweep after sizing, and remove the underflow as tailing...

Embodiment 2

[0022] Fine-grained hematite ore sample 1 in Wuding, Yunnan, containing Fe 38.52%, SiO 2 25.97%, the main mineral is hematite and its embedded particle size is fine, containing a small amount of magnetite, pyrite, limonite, etc.; gangue minerals mainly include chlorite, quartz, kaolinite, diabase, clay etc. After the hematite is crushed and screened, the ore is ground to -200 mesh, accounting for 85%, and water is added to adjust the concentration of the slurry to 20%. The cyclone continuous centrifugal separator is used for two graded desliming operations, and the overflow is used as tailings I for desliming. In addition; adjust the grit obtained after the double classification of the cyclone continuous centrifugal separator, adjust the pulp concentration to 25%, add sodium carbonate 4000g / t, water glass 200g / t, sodium fluorosilicate 100g / t in sequence , lead acetate 150g / t, MOH 800g / t, 2 # Oil 10g / t, flotation roughing after pulping; add lead acetate 50g / t, MOH 150g / t to ...

Embodiment 3

[0024] Fine-grained hematite ore sample No. 2 in Wuding, Yunnan, containing Fe 43.52%, SiO 2 27.97%, the main metal minerals in the ore are hematite and its embedded particle size is fine, containing a small amount of magnetite; the gangue minerals are mainly quartz, calcite, etc. After the hematite is crushed and screened, the ore is ground to -200 mesh, accounting for 90%, water is added to adjust the slurry concentration to 25%, and the cyclone continuous centrifugal separator is used for two graded desliming operations, and the overflow is removed as tailings I The grit obtained after the double classification of the cyclone continuous centrifugal separator is adjusted to a slurry, and the concentration is adjusted to 30%, and then the next step of flotation desiliconization operation is carried out; adding sodium carbonate 4500g / t, water glass 250g / t, Sodium fluorosilicate 150g / t, lead acetate 200g / t, MOH1000g / t, 2 # Oil 15g / t, flotation roughing after pulping; add lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com