Screw iron chip separation device for thread rolling machine

A separation device and thread rolling machine technology, applied in the field of machinery, can solve the problems that the separation device can only be applied to screws of a certain diameter, the gap between the conveying cylinder and the conveying worm cannot be adjusted, and the screws are mixed with iron filings and cooling oil, etc. To achieve the effect of simple structure, convenient operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

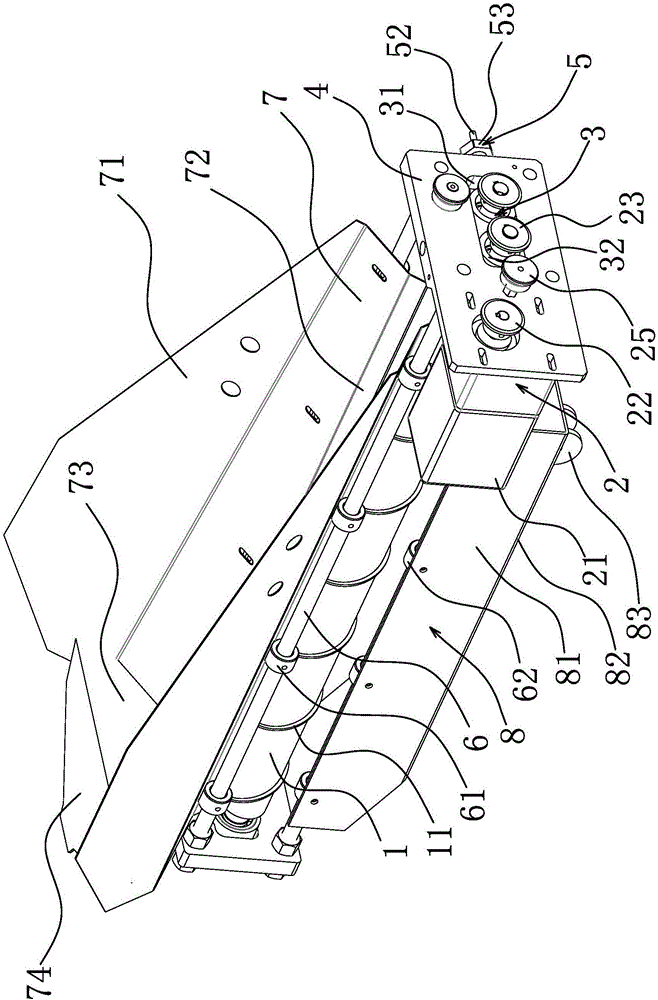

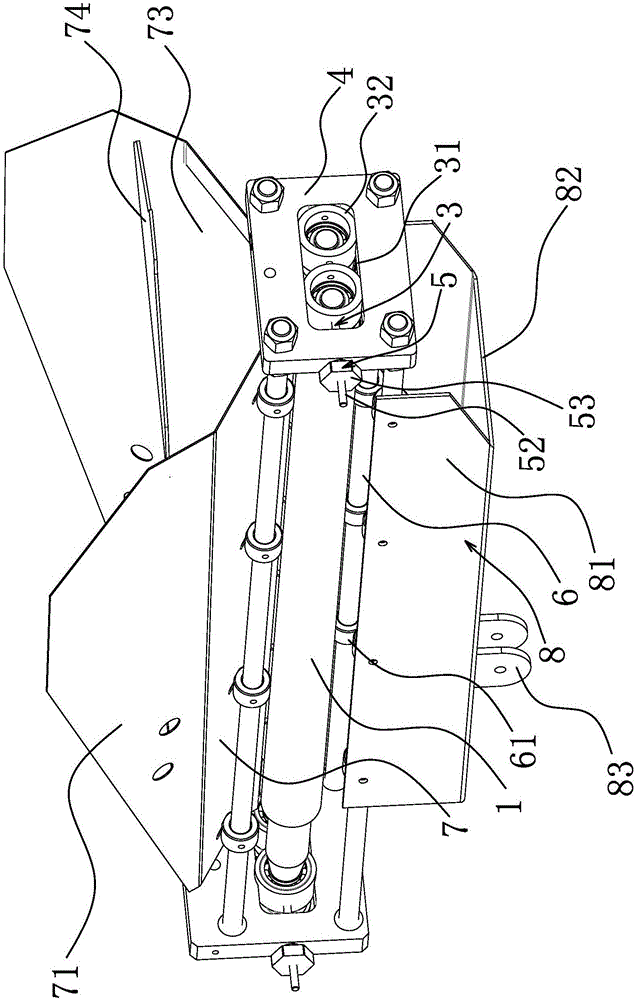

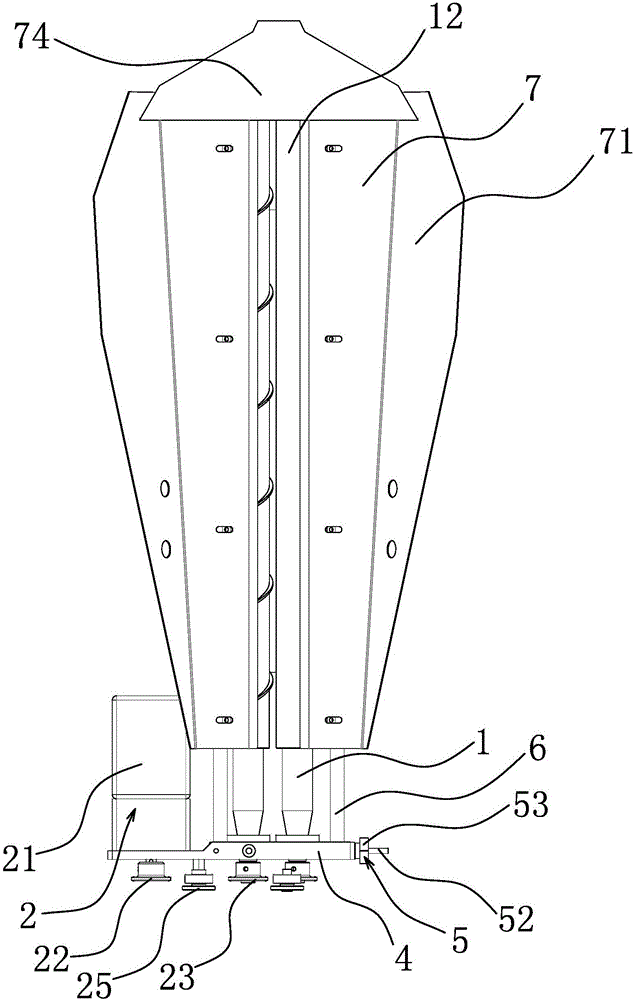

[0021] Such as Figure 1 to Figure 3 As shown, the screw chip separation device for thread rolling machine includes at least two conveying rods 1 corresponding to each other and arranged in parallel, at least one of the two conveying rods 1 has spirally distributed and self The spiral ribs 11 extending from one end of the conveying rod 1 to the other end form a gap 12 for the passage of iron filings between two adjacent conveying rods 1, and the conveying rods 1 are connected with a wire that enables the two adjacent conveying rods 1 to synchronize And the conveying driving mechanism 2 that rotates in the same direction in the circumferential direction is provided with a gap adjustment structure 3 between two adjacent conveying rods 1 that can make one of the two conveying rods 1 approach or move away from the remaining one so as to adjust the size of the gap 12 . Preferably, there are two conveying rods 1 , and the spiral rib 11 is arranged on one of the two conveying rods 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com