Guiding structure for assembling spray filling bottles

A guiding structure and bottle filling technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to assemble spray components, easy bending of straws, and inability to assemble spray filling bottles, so as to reduce interference, The effect of reducing error rate and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

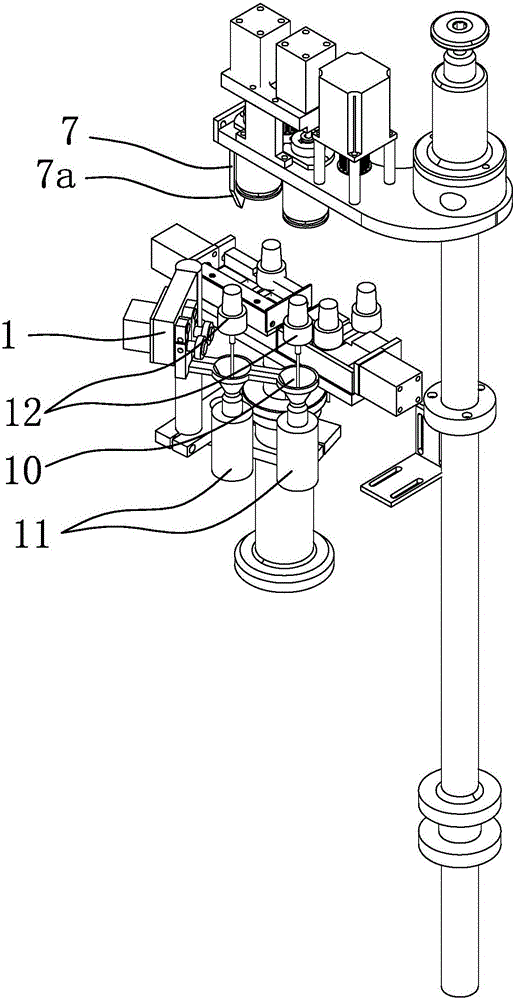

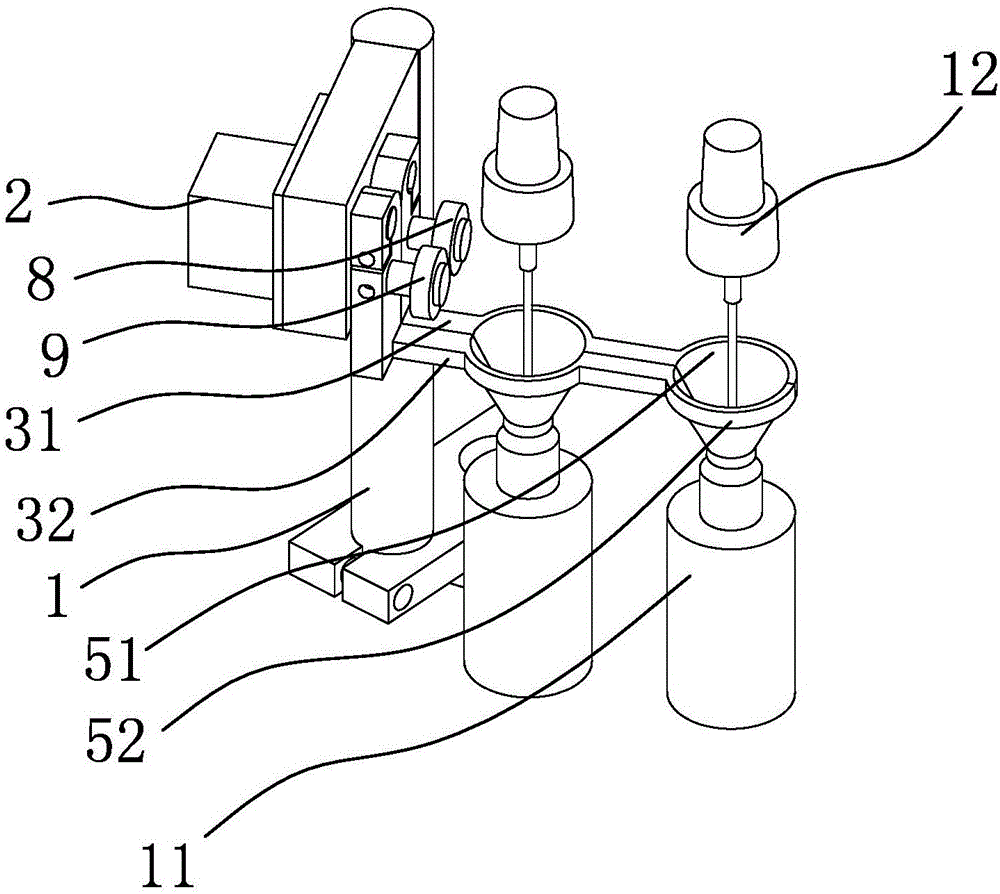

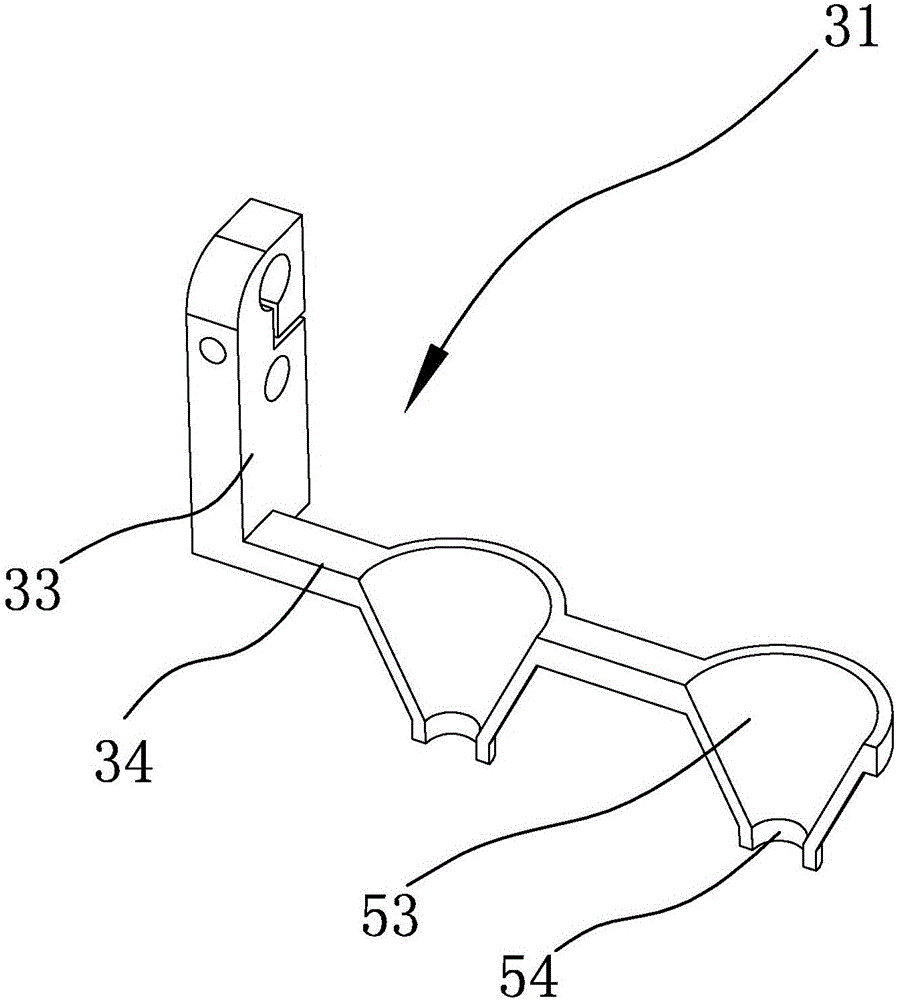

[0023] When the aerosol filling bottle is assembled, the spray assembly 12 needs to be installed at the mouth of the bottle body 11, and the suction pipe in the spray assembly 12 needs to be inserted into the bottle body 11. This assembly guide structure is used to guide the suction pipe, so that It can enter into the bottle body 11 smoothly. Such as figure 1 and figure 2 As shown, the assembly guide structure of the aerosol filling bottle includes a mounting base 1, a clamping cylinder 2 is fixed on the mounting base 1, and the output shaft of the clamping cylinder 2 is respectively connected with clamping arms 31 that can move closer together. With clamping arm two 32, clamping arm one 31 is provided with semi-bowl-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com