Chain sheet clamping device and chain sheet machining equipment provided with same

A technology of processing equipment and chain pieces, which is applied in the field of clamping devices for clamping chain pieces and chain piece processing equipment, can solve the problems of high structural symmetry accuracy, reducing processing production efficiency, and affecting processing production efficiency, etc., to achieve improvement Effects of processing productivity, improving processing productivity, and reducing moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

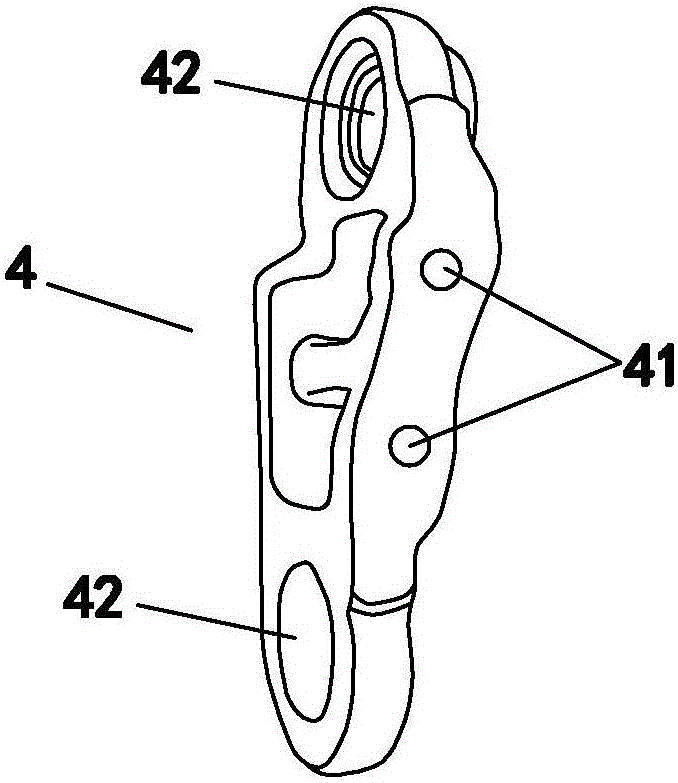

[0040] The structure of the chain sheet 4 involved in the present invention is as figure 2Shown is the chain plate body of the arc type at both ends, on which there are bolt holes 41 and pin holes 42, such as Figure 4 Shown in is the schematic diagram of the structure of the chain piece 4 constituting the chain link.

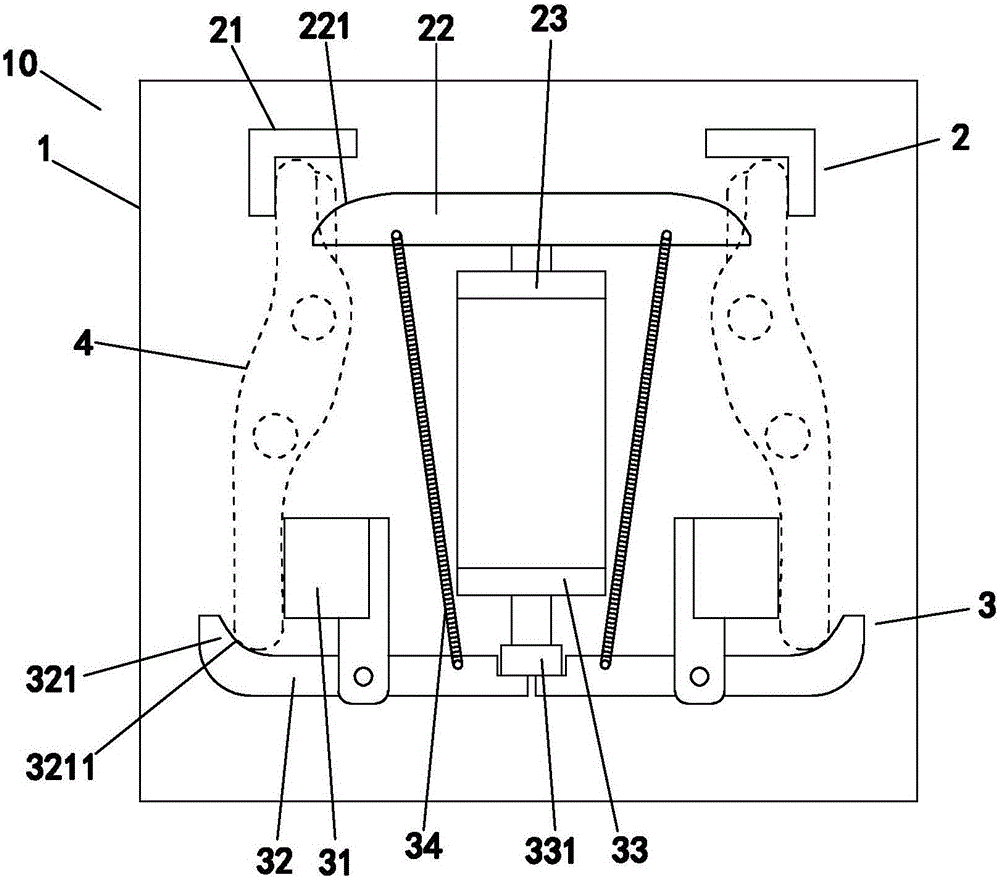

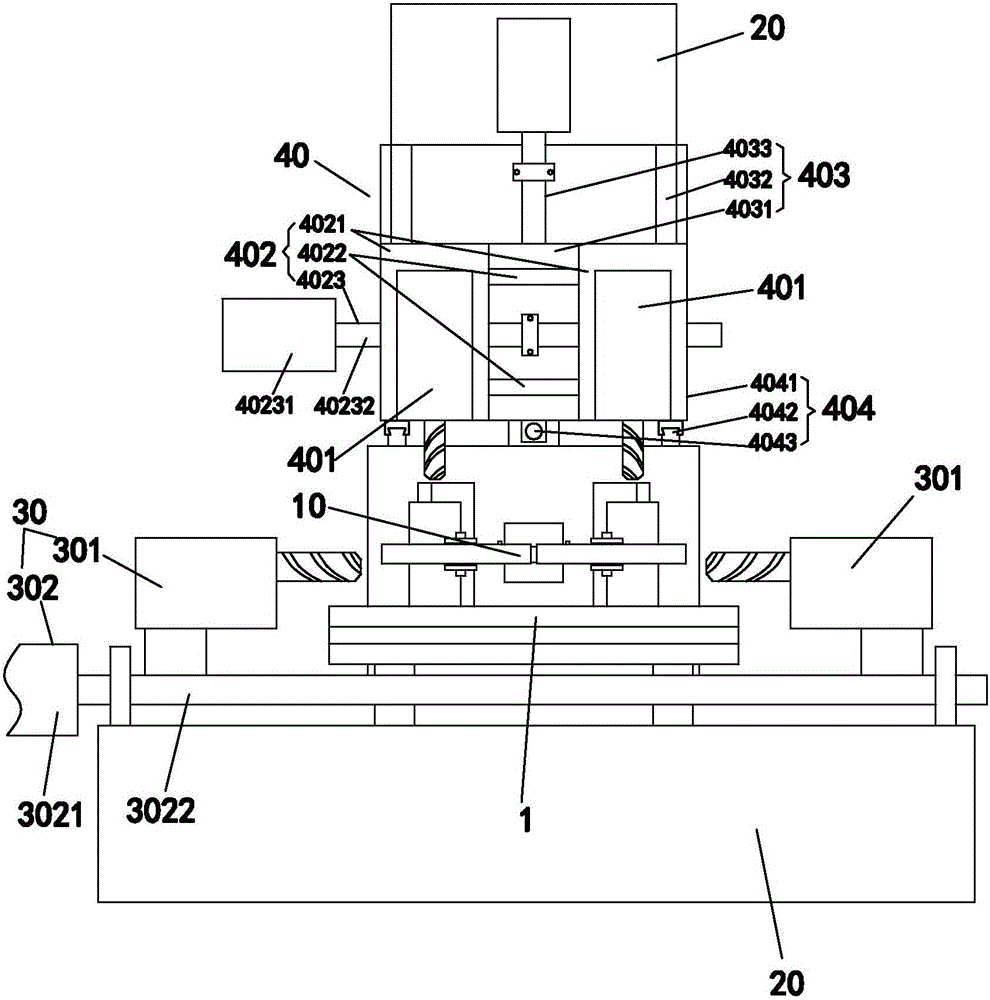

[0041] A chain clamping device 10 disclosed in the present invention is a special clamp for chains, which has the characteristics of accurate positioning base surface, reliable and rapid clamping, such as figure 1 As shown, it includes a mounting base 1, a first-end holding mechanism 2 and a second-end holding mechanism 3; the chain plate clamping device 10 is mainly used in chain plate drilling and boring processing equipment, of course, if the present invention discloses The structure can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com