Machining tool and machining method of steering knuckle bearing hole

A steering knuckle and bearing hole technology, which is applied in the field of auto parts processing, can solve problems such as high cost, low production efficiency, and inconvenient clamping of the steering knuckle, and achieve the effects of improving efficiency, saving time, and reducing the number of clamping times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

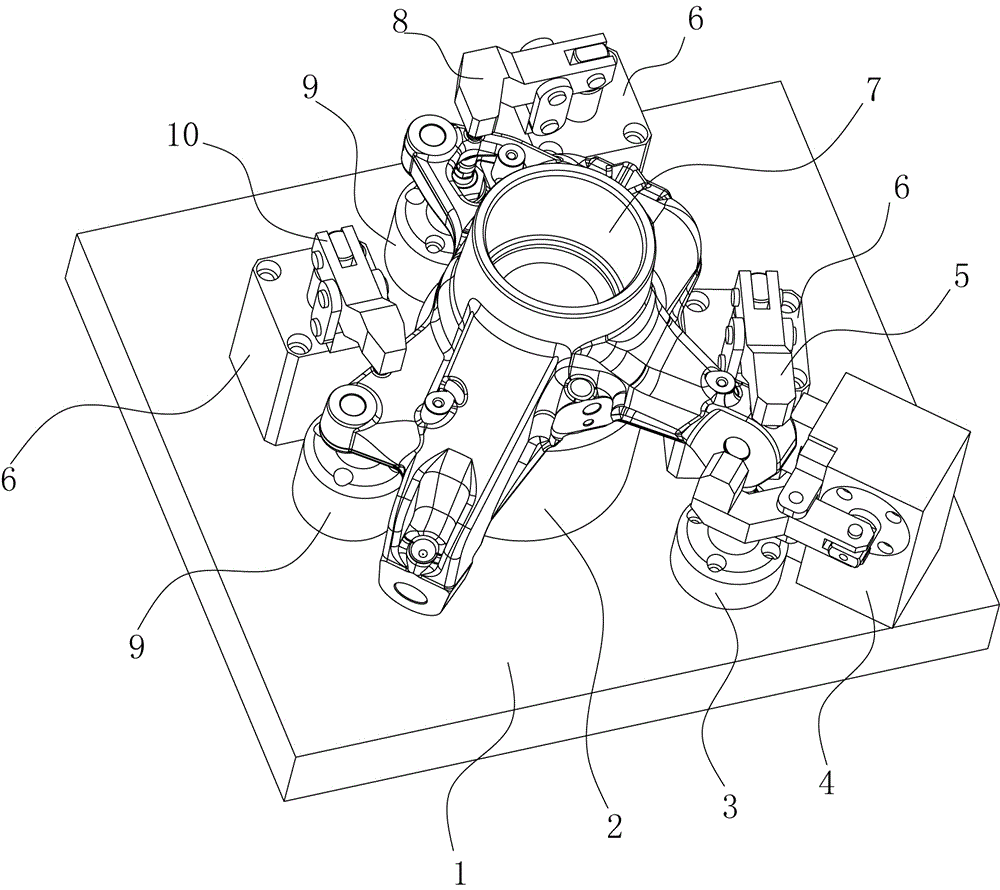

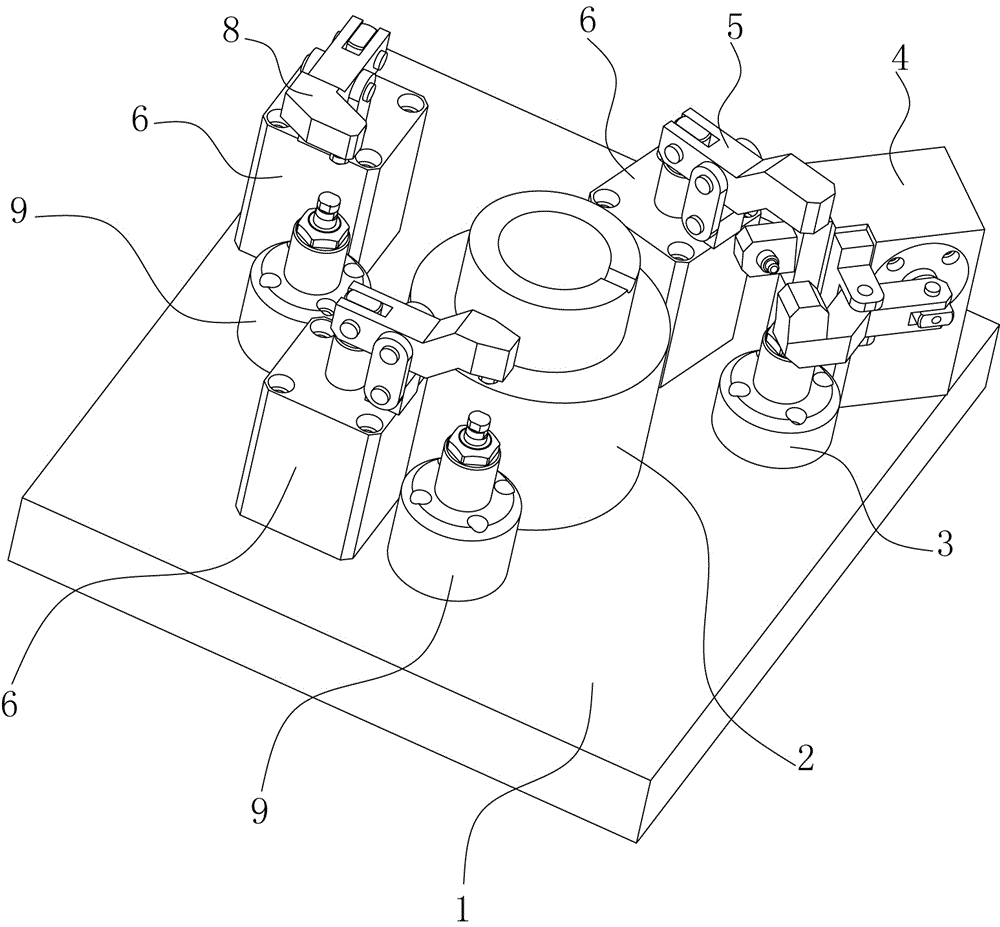

[0040] like figure 1 As shown, a tooling for processing steering knuckle bearing holes, the tooling includes a fixture, and the fixture includes a base plate 1, a positioning shaft 2, a support member, a circumferential positioning clamping device 4, an auxiliary pressing device and a pressing device.

[0041] The bottom plate 1 is a rectangular block, and the center of the bottom plate 1 is provided with a through hole X.

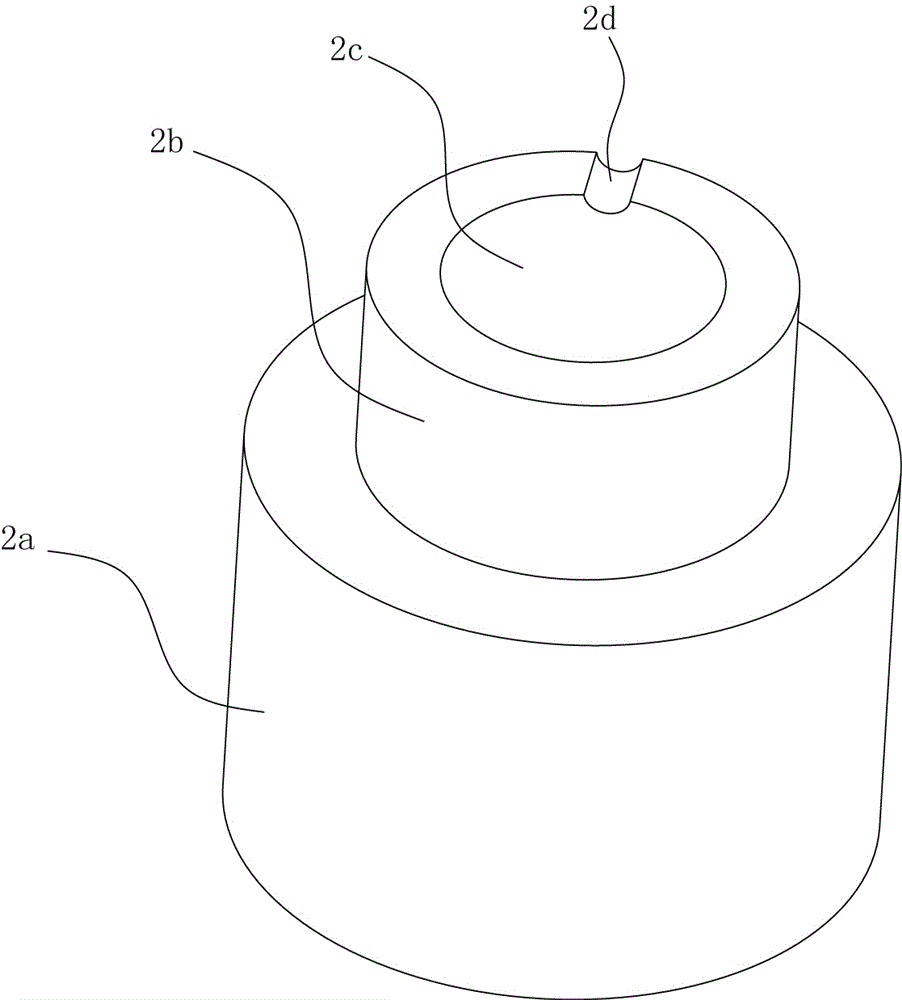

[0042] The positioning shaft 2 is a stepped shaft with two shaft sections, the lower shaft section 2a and the upper shaft section 2b are arranged concentrically, and the upper shaft section 2b matches the cover mounting hole 7h on the steering knuckle 7 to be processed and A through hole D2c is concentrically formed on the top surface thereof.

[0043] The support components include a support cylinder A3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com