A kind of mobile intelligent mechanical arm and its working method

A technology for robotic arms and staff, applied in the field of manufacturing, can solve the problems of increased maintenance costs, a lot of manpower and material resources, and high prices for enterprises, so as to solve the problem of movement and handling, facilitate handling and movement, and ensure achievability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

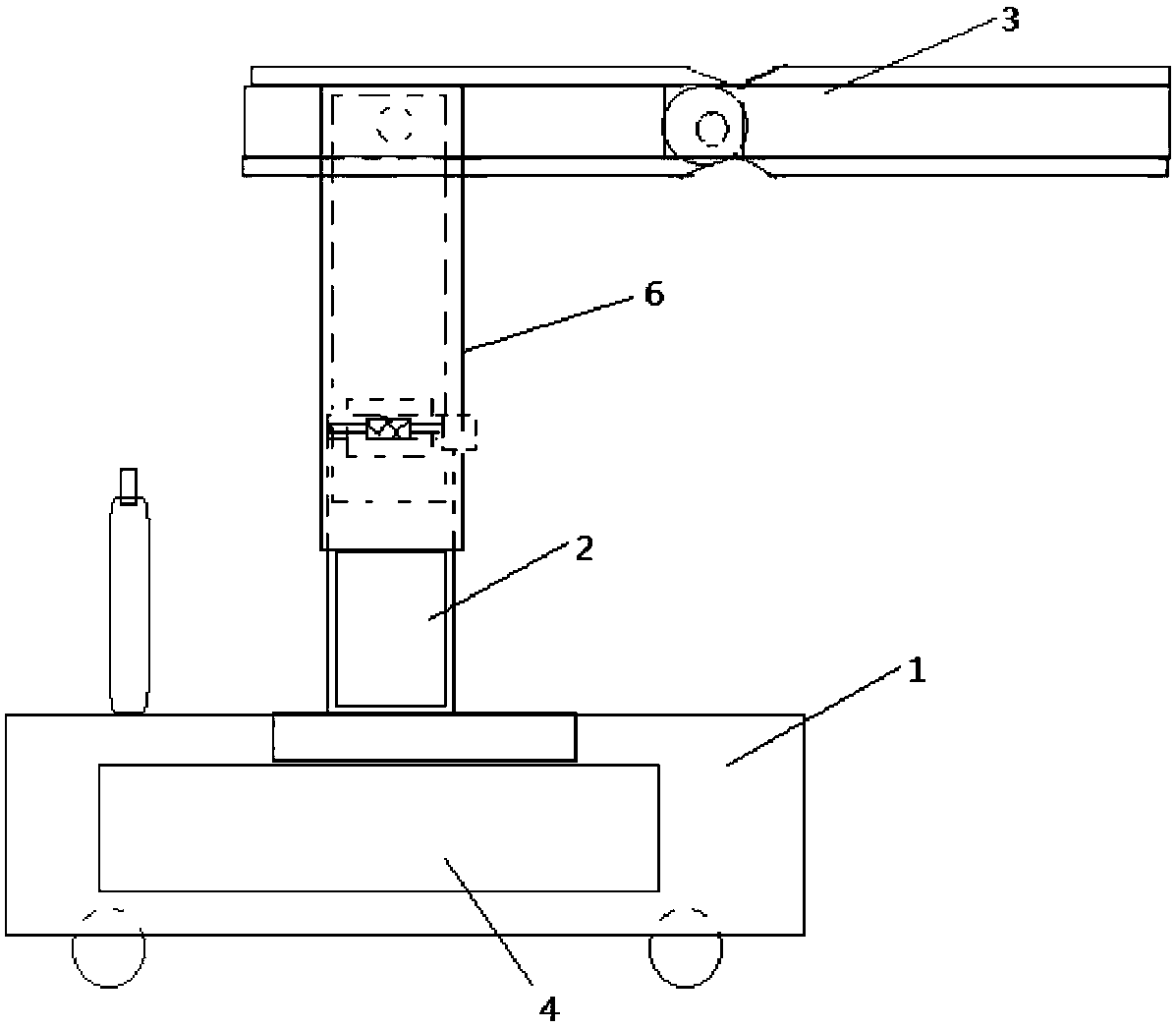

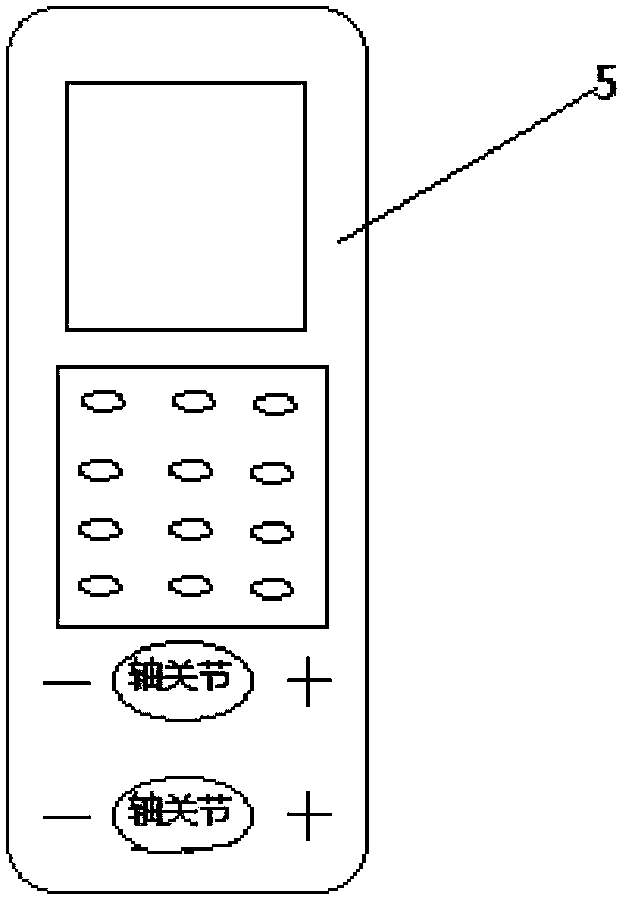

[0040] As shown in the figure, an intelligent mechanical arm that is easy to move includes: a base 1, a column 2, a shaft joint 3, a control device 4 and a remote control 5, wherein a storage box 6 is provided on one side of the column 2 , the control device 4 is provided with a drive control module, an execution control module, a telescopic control module, an alarm control module, a remote control control module and a central control module;

[0041] The relationship between the above components is as follows:

[0042] The column 2 is arranged on the base 1, the shaft joint 3 is connected with the column 2, and the shaft joints 3 are rotatably connected in pairs, and the connection between the two shaft joints 3 is provided with telescopic control mechanism, the control device 4 is set in the base 1, the remote controller 5 is connected to the control device 4 through wireless communication; the drive control module is connected to the base 1, and the execution control module...

Embodiment 2

[0049] The structure of the manipulator in the working method of the mobile intelligent manipulator described in this embodiment is the same as that in the first embodiment.

[0050] like figure 1 and figure 2 An intelligent mechanical arm that is easy to move is shown, including: a base 1, a column 2, a shaft joint 3, a control device 4 and a remote controller 5, wherein a storage box 6 is provided on one side of the column 2, and the The control device 4 described above is provided with a drive control module, an execution control module, a telescopic control module, an alarm control module, a remote controller control module and a central control module;

[0051] The relationship between the above components is as follows:

[0052] The column 2 is arranged on the base 1, the shaft joint 3 is connected with the column 2, and the shaft joints 3 are rotatably connected in pairs, and the connection between the two shaft joints 3 is provided with telescopic control mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com