Gating system of injection mold

A pouring system and injection mold technology, applied in the field of injection mold design and manufacturing, can solve problems such as difficulty in ensuring product quality, waste in the production process, uneven glue feeding, etc., to solve injection problems, reduce material loss, and solve product surface shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

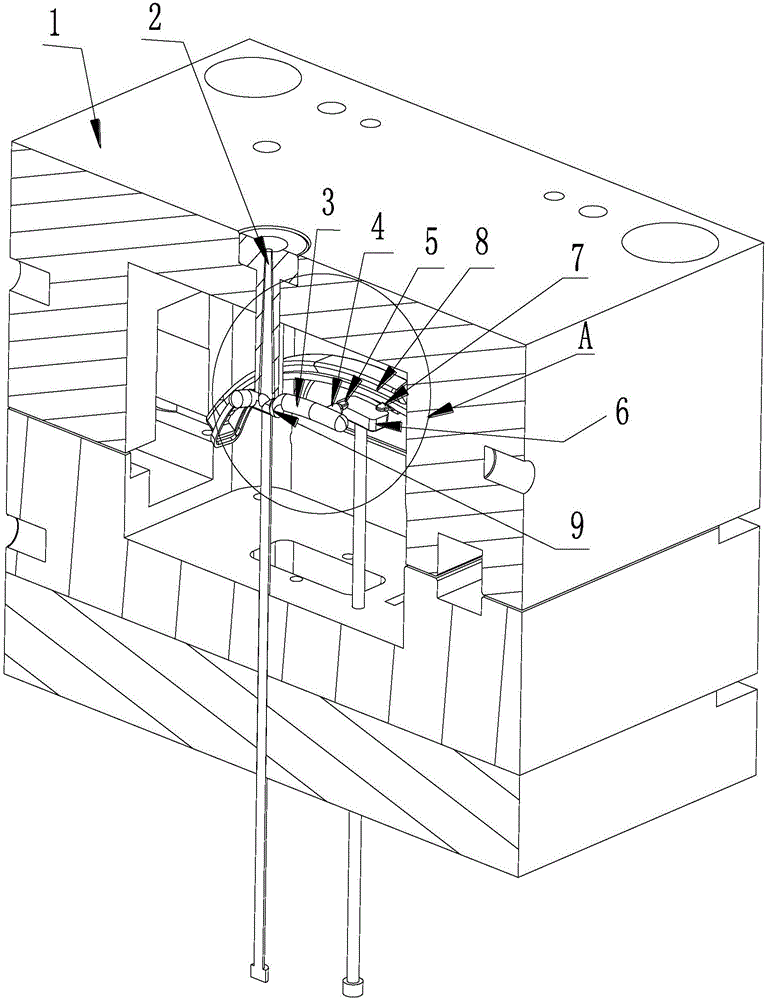

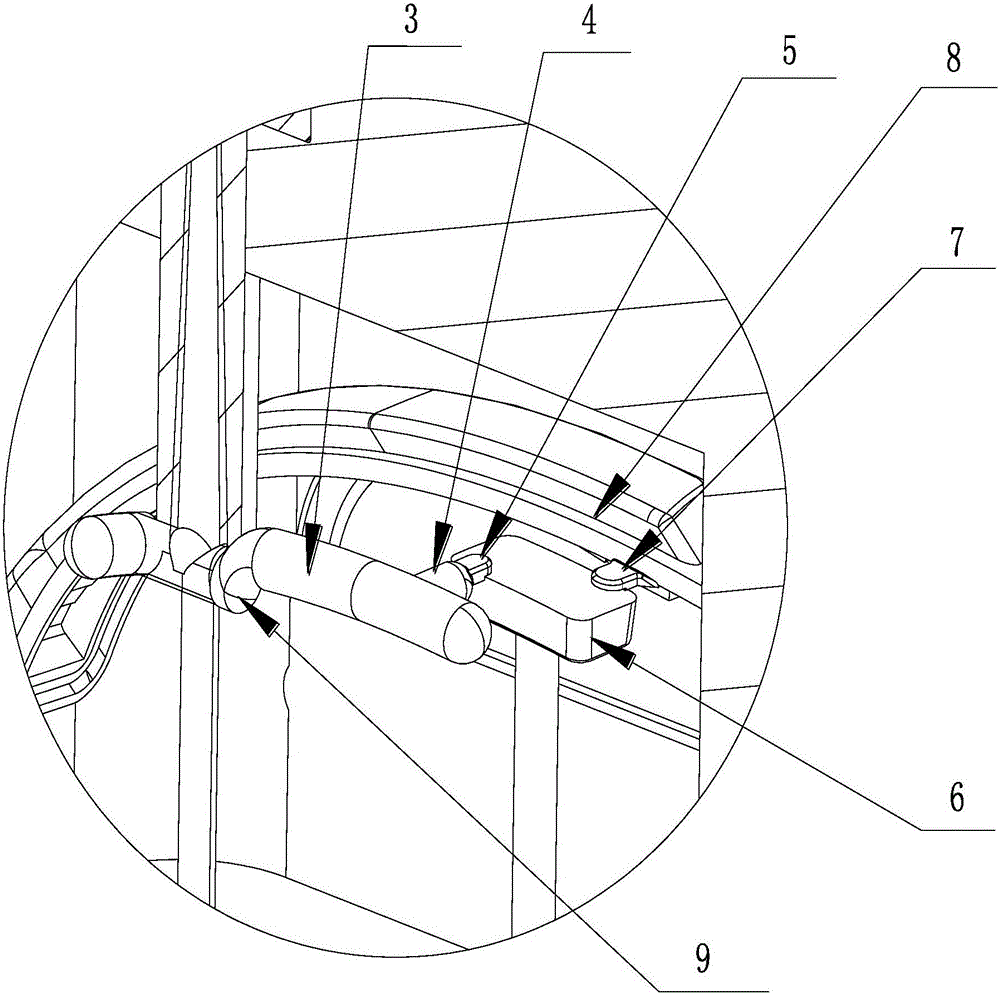

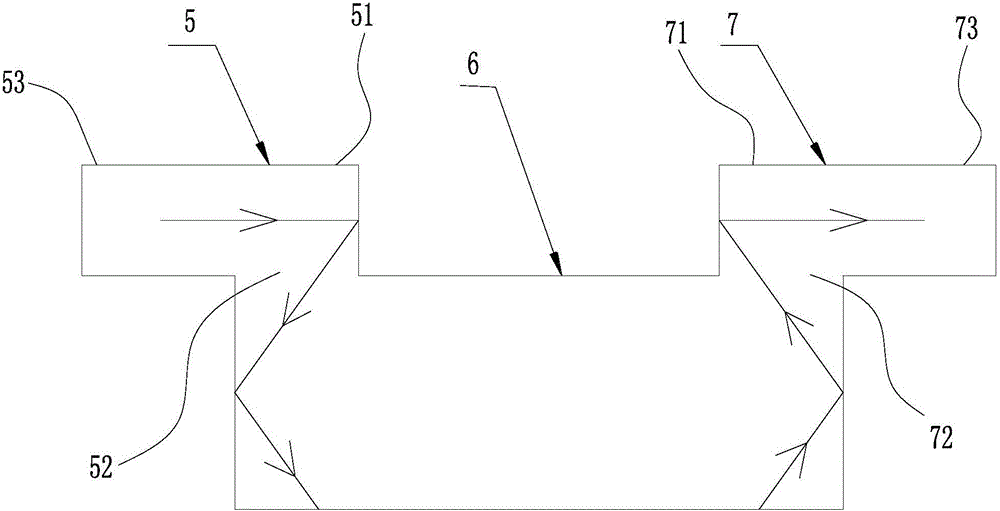

[0022] like Figure 1~2 The gating system of the injection mold shown includes a mold main body 1, a main rubber channel 2, a main channel 3, a runner 4, a release bag 6 and a bridge 5 connecting the runner 4 and the release bag 6; the main rubber channel 2 is vertical Built directly into the mold body 1, the main channel 3, the runner 4, and the release package 6 are all built into the mold main body 1; one end of the main channel 3 communicates with the lower end of the main rubber channel 2, and the other end communicates with the runner 4; the release package 6 The side close to the runner 4 communicates with the runner 4 through the bridge 5, and the side of the release package 6 away from the runner 4 is provided with a glue inlet section 7 communicating with the mold cavity 8 of the part, the main channel 3, the shunt Road 4, release bag 6 and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com