Self-adaptive telescopic footboard device for train platform

A telescopic pedal, self-adaptive technology, applied in the directions of transportation and packaging, railway car body parts, etc., can solve the problems of passengers falling, rubber is easy to age, passengers' personal safety items are lost, etc., and achieve the effect of reasonable design and scratch prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

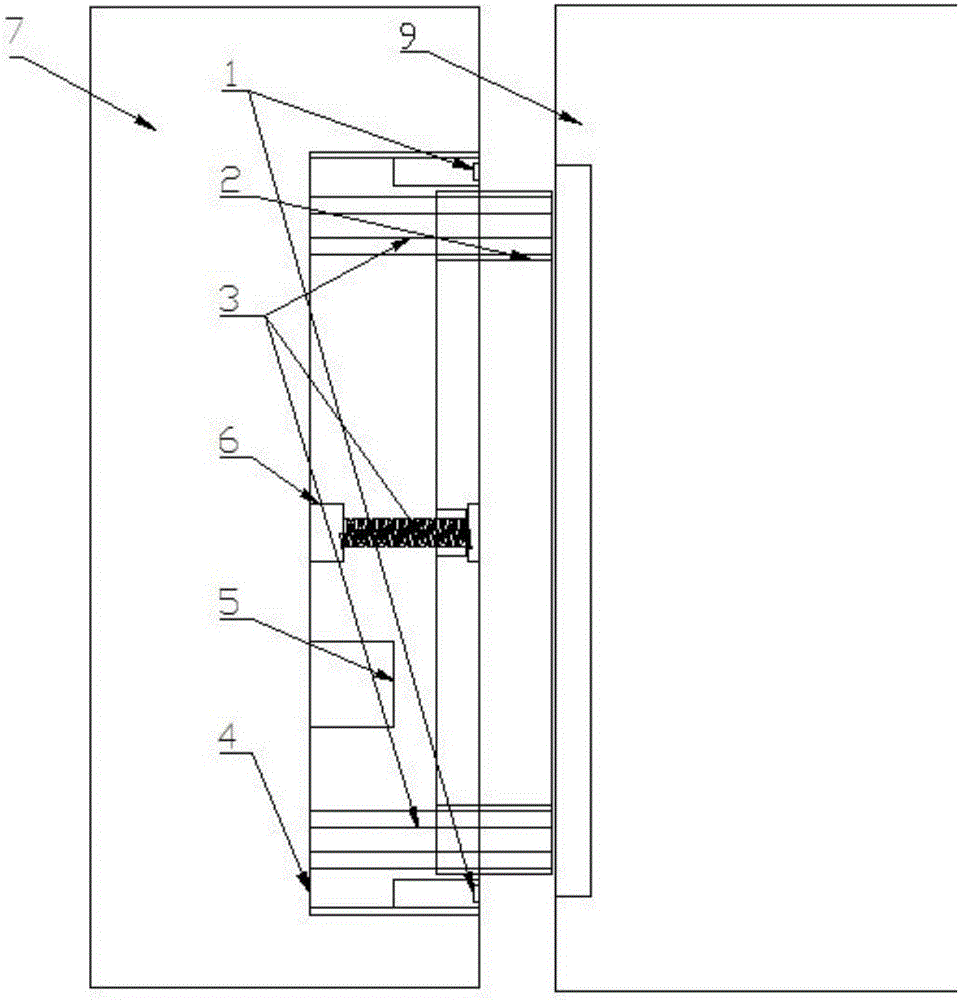

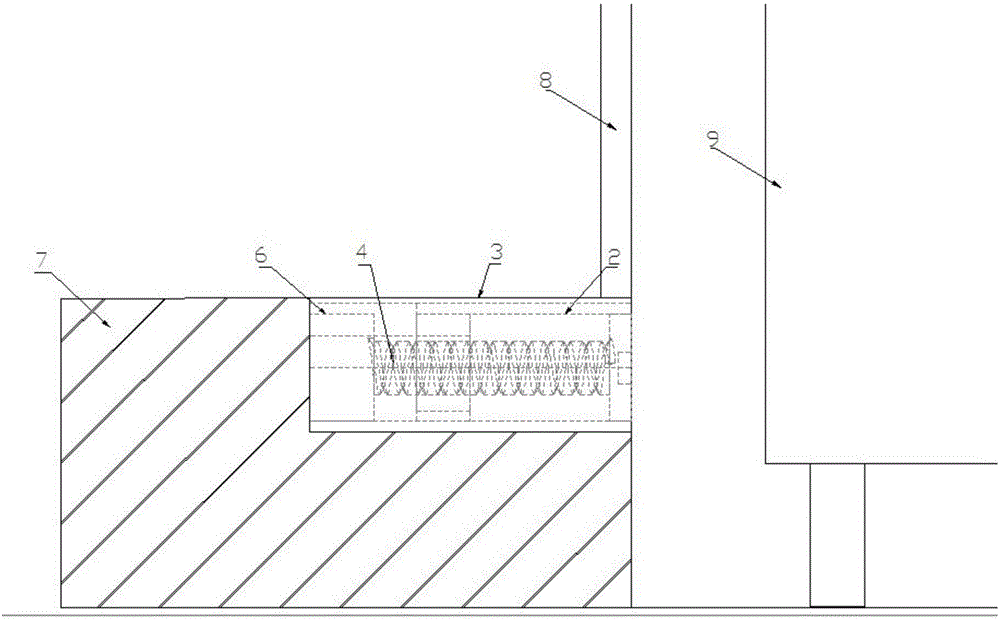

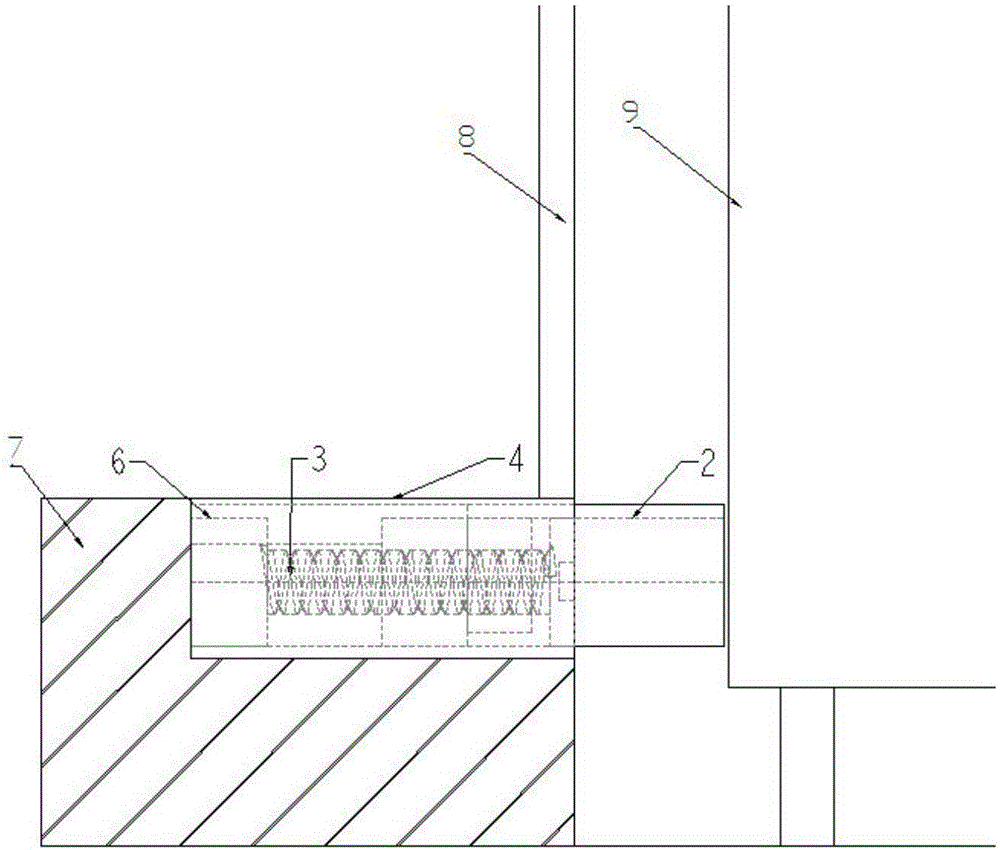

[0021] The structure of this embodiment is as Figure 1 to Figure 5 As shown, an adaptive telescopic pedal device for a train platform includes a laser ranging sensor 1, a telescopic pedal 2, a screw guide rail 3, a mounting bracket 4, a signal controller 5, a servo motor 6, a platform 7, and a platform screen door 8 , Train carriage 9.

[0022] The mounting bracket is horizontally and fixedly installed inside the platform, and has an opening on one side facing the compartment, and a telescoping pedal is linked in the opening through the drive assembly. Among them, the driving component is a screw guide rail, which includes a transmission screw and a V-shaped guide rail; the transmission screw is connected with a servo motor arranged on the side of the mounting bracket away from the carriage through a coupling, and the V-shaped guide rail includes The static block installed at both ends of the guide rail and the sliding block installed on the guide rail, the V-shaped guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com