Auxiliary collecting ship of automatic floating object cleaning ship

A technology for automatic cleaning and floating objects, which can be used in motor vehicles, special-purpose ships, ships, etc., to solve the problems of slow sailing speed, affecting collection efficiency, and high noise, achieving convenient operation and use, improving ecological environment, and good collection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

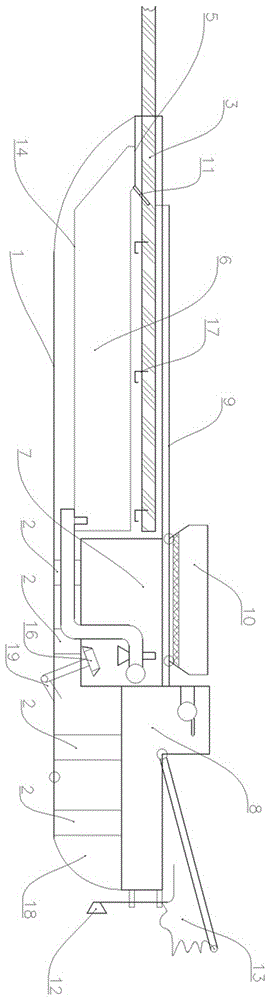

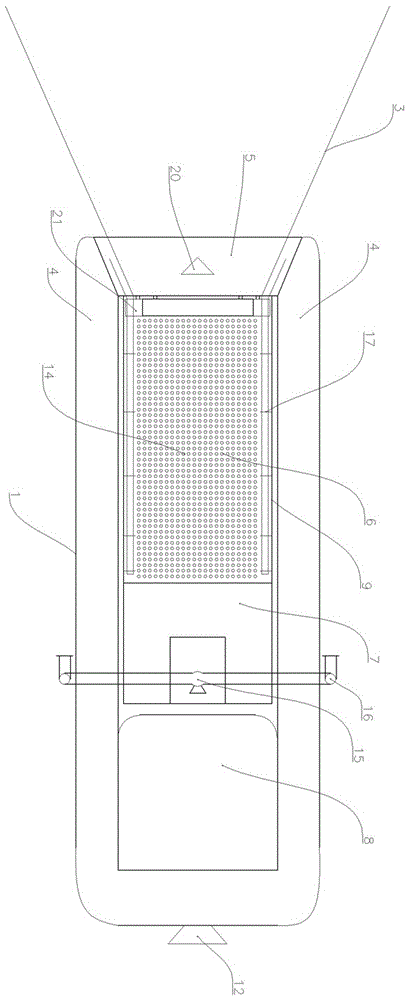

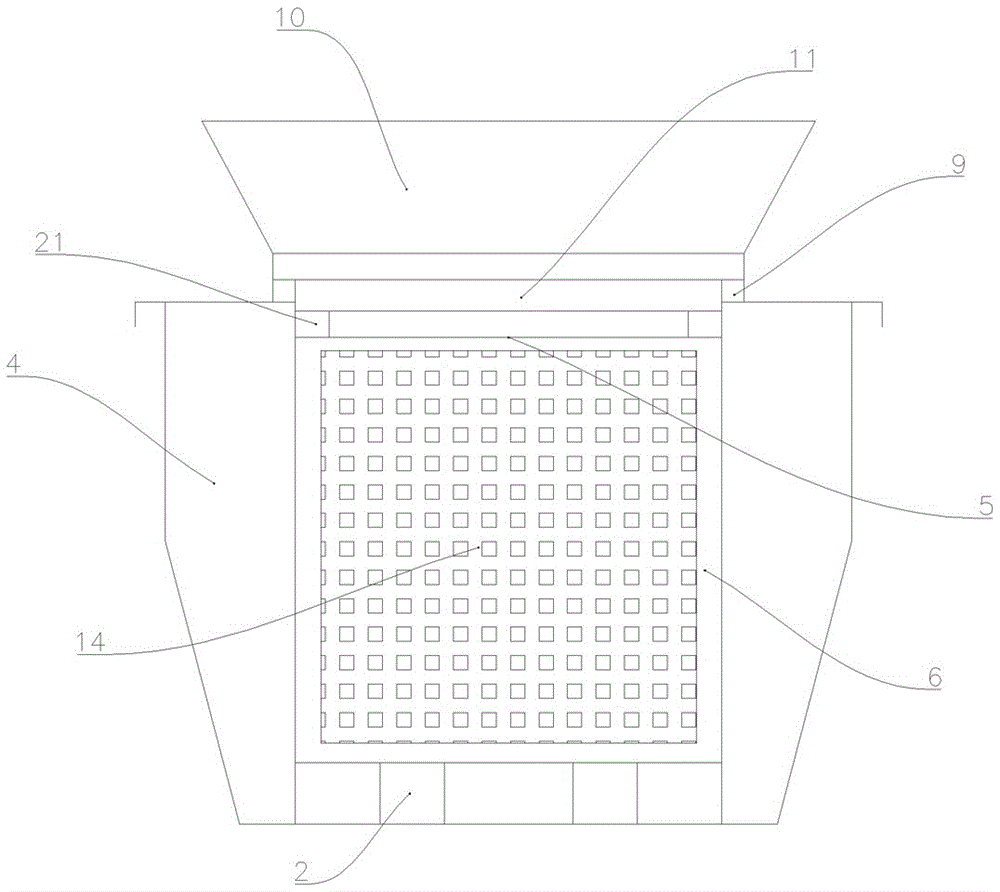

[0020] Such as figure 1 As shown, the supporting collection ship of the floating debris automatic cleaning ship described in this embodiment includes a collection ship 1, which is characterized in that the two sides of the collection ship 1 are symmetrically provided with ax-shaped main buoys 4 in section, and the collection ship 1 Between the two main buoyancy tanks 4 at the top, a horn-shaped opening is provided, and the bottom of the horn-shaped opening is a guide plate 5, which is arranged below the water surface. After the guide plate 5, a collecting bin 6, machine Storehouse 7, operating storehouse 8, wherein said operating storehouse 8 is arranged on the afterbody of collecting ship 1, and the bottom of operating storehouse 8 is provided with buoyancy balance storehouse 18; A garbage storage frame 10 movable back and forth is set on the slide rail 9 .

[0021] The water inlet gate 11 is set at the rear of the guide plate 5, a point change propeller 12 is set at the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com