Prefabricated floor slab reinforcement cage member, floor slab, member assembling method and floor slab construction method

A construction method and steel cage technology, applied in the direction of floors, building components, structural elements, etc., can solve the problems of difficult construction, cramped manual work space, and complicated reinforcement of connection nodes, and achieve high construction efficiency, convenient and quick dismantling, The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

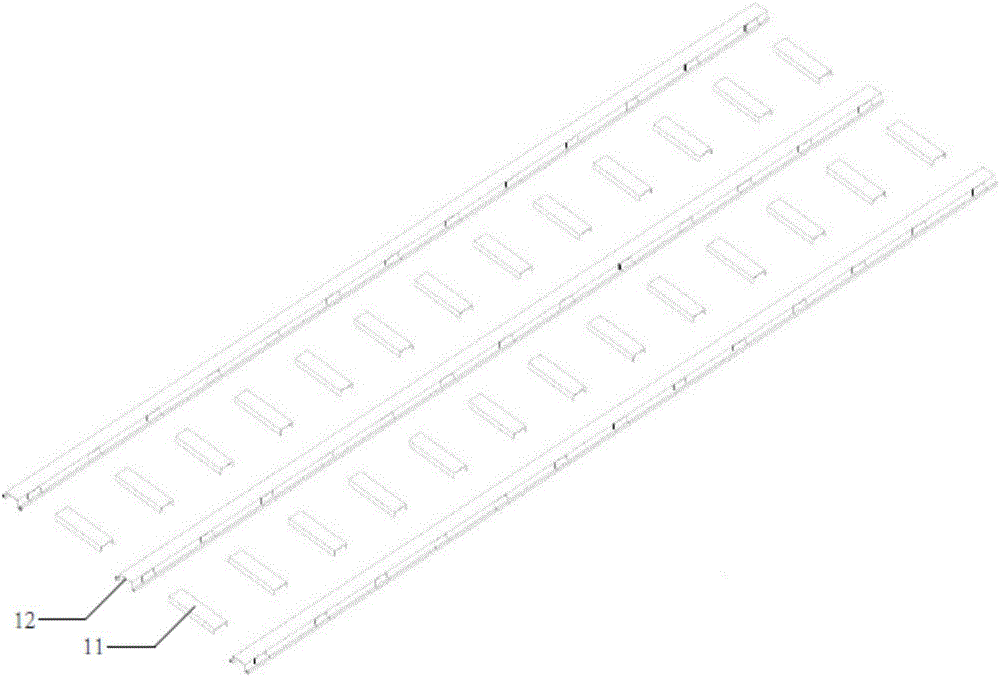

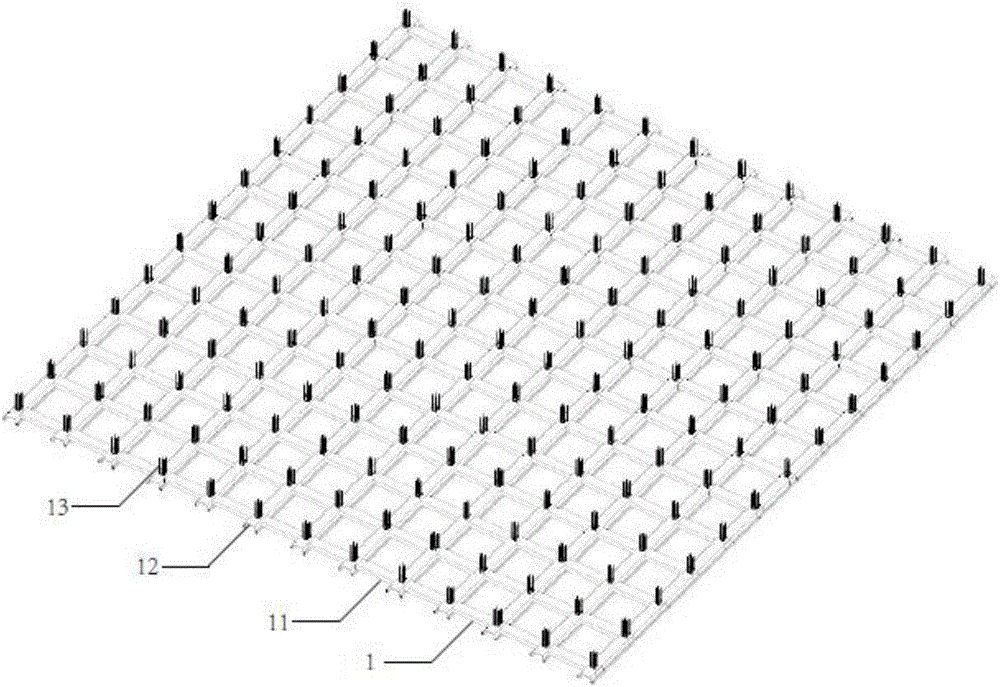

[0035] The prefabricated floor reinforcement cage member of the present invention comprises a base form 1, a steel bar truss 2 installed on the upper side of the base form 1, and the base form 1 comprises a plurality of longitudinal support templates 11 arranged in parallel, A number of horizontal supporting formworks 12 are arranged between the supporting formworks 11, the longitudinal supporting formworks 11 are integrated with the horizontal supporting formworks 12 on both sides, the steel bar trusses 2 are arranged above the horizontal supporting formworks 12, Reinforcing bars are provided along the top of the longitudinal supporting formwork 11 to connect all the reinforcing bar trusses 2 as a whole. Wherein the intersection of the longitudinal supporting formwork 11 and the transverse supporting formwork 12 is provided with a positioning piece 13, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com