Parallel flow micro-channel condenser capable of defrosting by using heat pump

A technology of micro-channel and parallel flow, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of heat exchanger frosting, unfavorable water flow, and the inconvenience of water flow when the multi-hole harmonica flat tube is placed horizontally, and achieves thermal High exchange efficiency, convenient defrosting and flowing water, widening the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A heat pump defrosting parallel-flow micro-channel condenser of the present invention will be further described in detail with reference to the accompanying drawings.

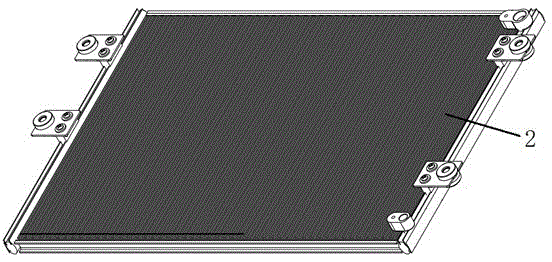

[0015] see figure 1 and figure 2 , a kind of heat pump defrosting parallel-flow micro-channel condenser of the invention comprises a parallel-flow micro-channel condenser, and the parallel-flow micro-channel condenser is composed of a micro-channel flat tube, fins, a left side liquid collector, a right side The liquid collecting pipe is formed by the upper fixed plate, the lower fixed plate, the pressure plate of the intake pipe, the pressure plate of the liquid outlet pipe and the distributed brackets.

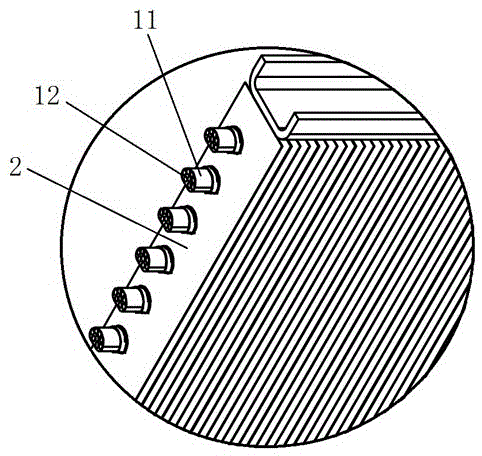

[0016] The microchannel flat tube is composed of a "D" shaped tubular body 11 and a honeycomb circular microchannel 12 inside the "D" shaped tubular body 11 .

[0017] The fins are sheet-shaped fins 2 .

[0018] The micro-channel flat tube composed of the "D"-shaped tubular body 11 and the honeycomb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com