Titanium-steel composited warhead shell

A warhead and casing technology, which is applied in the field of warhead structure, can solve the problems of strengthening the damage capability of the warhead, and achieve the effects of improving damage capability, increasing the amount of charge, and good penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

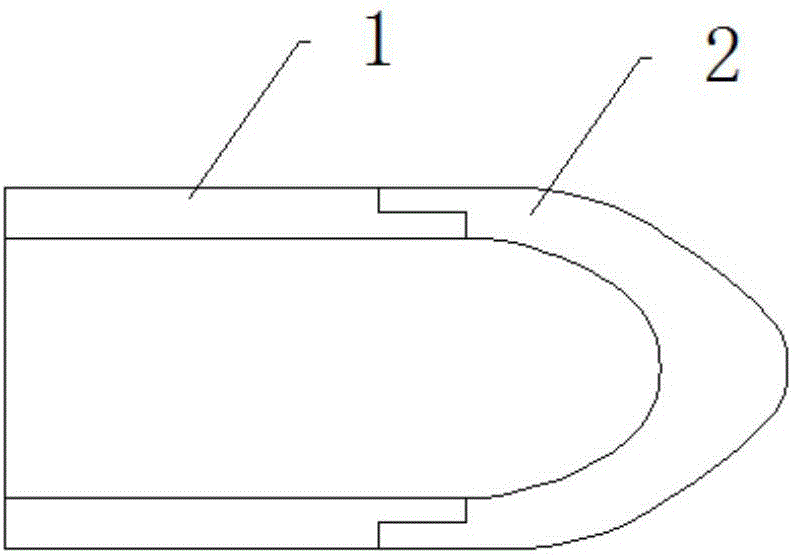

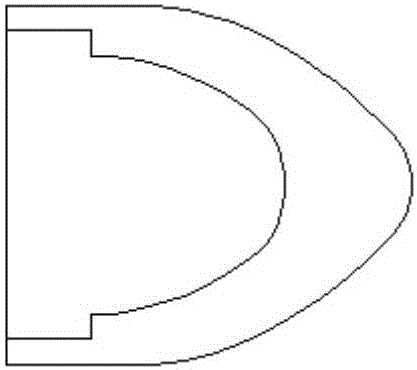

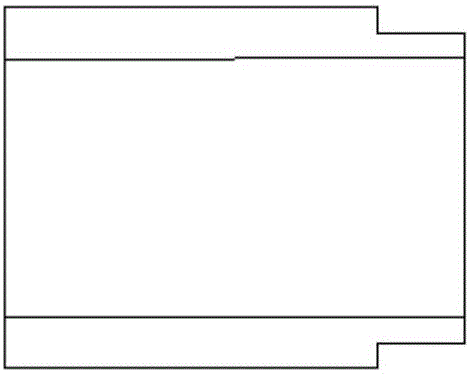

[0027] Such as figure 1 , 2 As shown in and 3, a titanium-steel composite warhead shell, the warhead shell is a pointed oval shell structure with a total length of 27.18mm and an outer diameter of 12.59mm, and the outer contour of the head is The three arcs with radii of 9.66mm, 16.11mm and 2.31mm are evenly transitioned, and the inner contour passes through two arcs with radii of 10.38mm and 3.21mm respectively, the inner diameter is 8.99mm, and the inner cavity depth is 22.76mm; For the penetrating part 2 and the main part 1, the material of the penetrating part 2 is 921A steel, and the material of the main part 1 is TC4 titanium alloy;

[0028] The penetrating part 2 is located at the front end of the warhead shell, the main body part 1 is located at the rear end of the warhead shell, the penetrating part 2 is 14.18 mm long, and the main body part 1 is 13 mm long; The tail end of part 2 is processed with a step, and the front end of the main part 1 is processed with a rev...

Embodiment 2

[0033] Such as Figure 4 , 5 As shown in and 6, a titanium-steel composite warhead shell, the warhead shell has a pointed oval shell structure with a total length of 60.39mm and an outer diameter of 27.98mm, which is divided into penetrating parts 2 and the main part 1, and the penetration part 2 and the main part 1 are connected by interference fit; the material of the penetration part 2 is 40CrMnSiB steel, and the material of the main part 1 is TC6 titanium alloy;

[0034] Wherein, the penetrating part 2 is the outer layer of the warhead shell, with a total length of 60.39mm and an outer diameter of 27.98mm. Excessive, the inner contour passes through two circular arcs with radii of 5.41mm and 27.46mm respectively, the inner diameter is 25.98mm, and the inner cavity depth is 57.68mm; the main part 1 is the inner layer of the warhead shell, with a total length of 57.68mm , the outer diameter is 25.98mm, the outer contour of the head passes through two arcs with radii of 5.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com