Fiber Bragg grating sensor-based local crack real-time monitoring method

A technology of optical fiber Bragg and real-time monitoring, which is applied in the direction of optical testing flaws/defects, etc., and can solve the problems of complex equipment, lightness and insensitivity of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the drawings and embodiments.

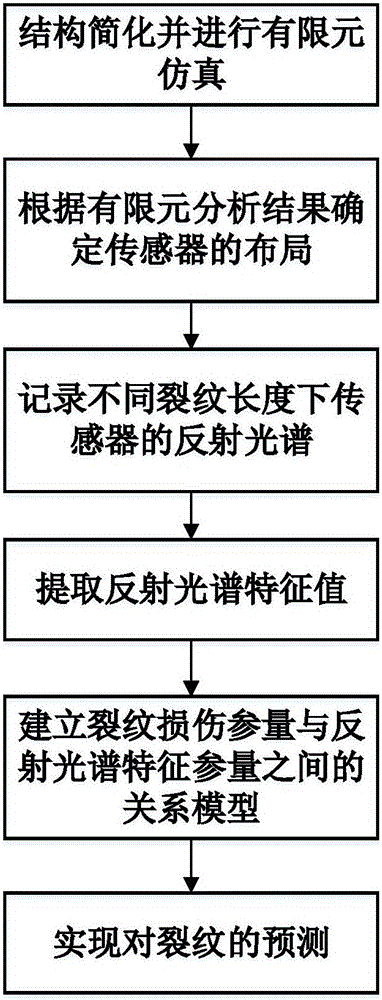

[0040] The present invention provides a real-time monitoring method for local cracks based on fiber Bragg grating sensors. The overall process diagram of the method is as follows figure 1 Shown. The method is specifically implemented through the following steps:

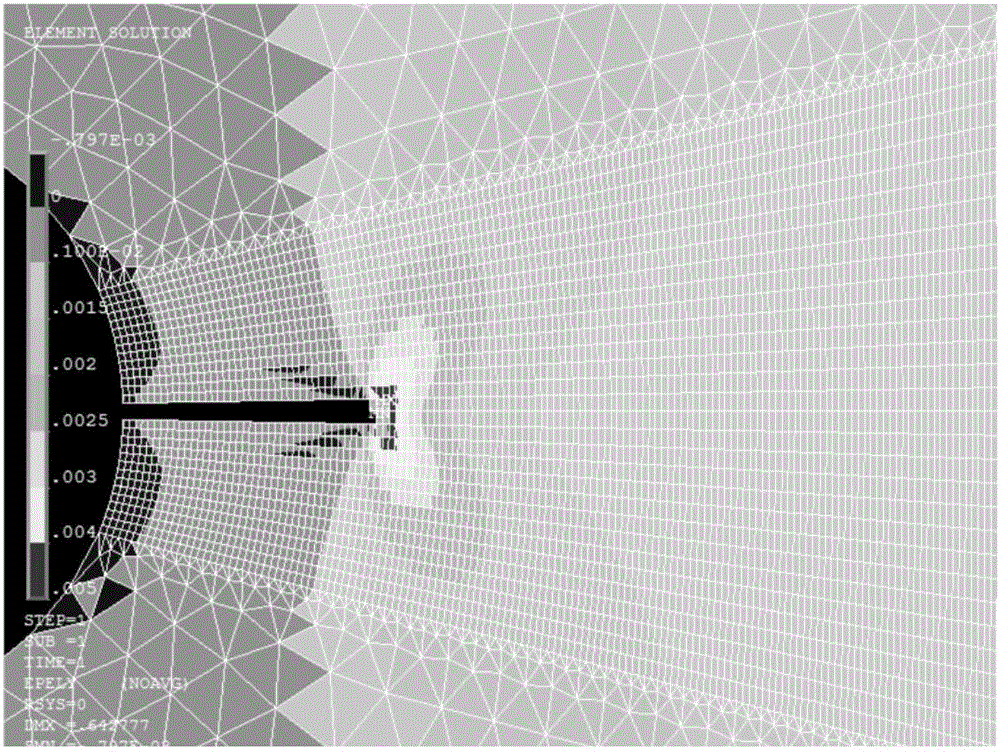

[0041] The first step is to perform a finite element analysis on the aluminum alloy plate with a central circular hole subjected to uniaxial fatigue load;

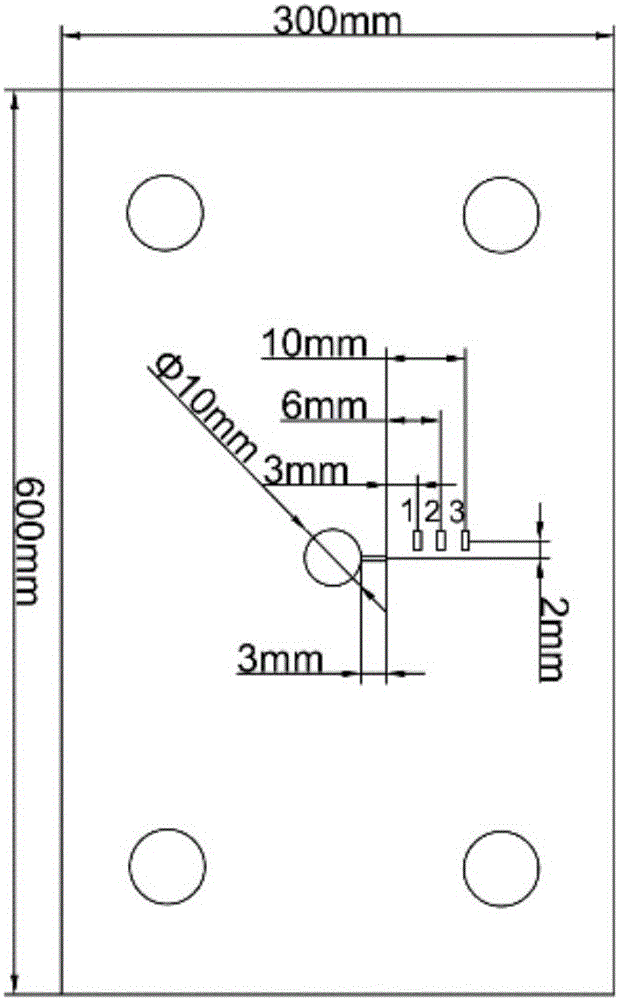

[0042] The most common structure and load situation in simulation engineering is that an infinite flat plate with a central circular hole is subjected to uniaxial fatigue load. This embodiment uses an aluminum alloy plate test piece with a size of 600mm×300mm×2mm, a hole with a diameter of 10mm is opened in the middle, and a 3mm notch is prefabricated on the edge of the hole by wire cutting. The maximum test stress is 75MPa, the stress ratio is 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com