FC type optical fiber movable connector part assembling device

A technology for movable connectors and assembling devices, which is applied to optical components, light guides, optics, etc., can solve the problems that workers are not easy to grip and apply force, take a long time, and short metal sleeves, so as to achieve convenient holding and application. force, speed up assembly, and avoid the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

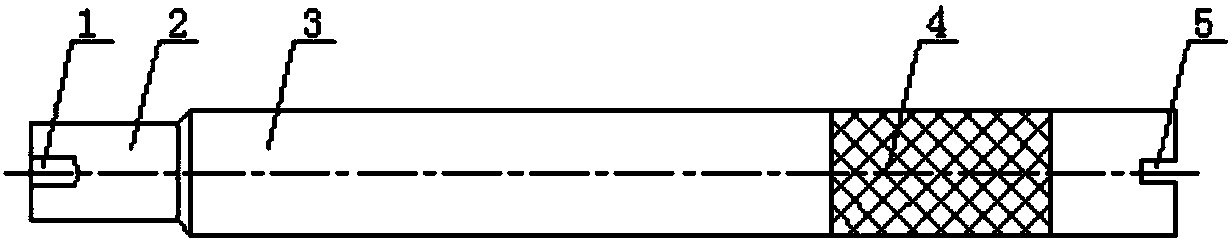

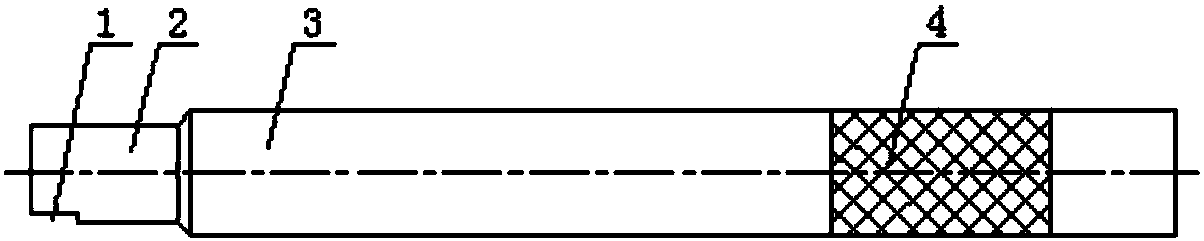

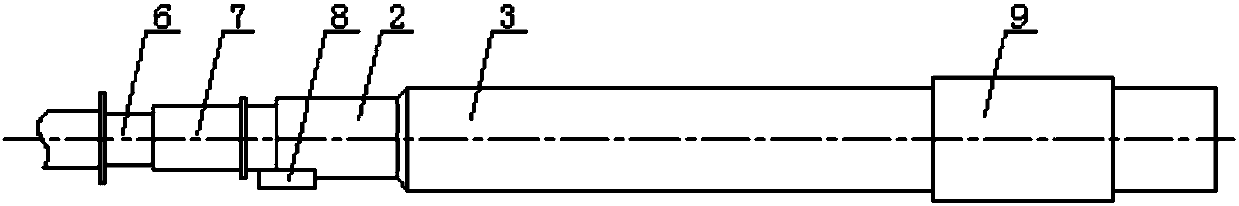

[0021] An FC-type optical fiber movable connector assembly device, including a chuck 2 and a handle 3, the chuck is cylindrical, and a mounting hole 10 is formed on its axis, and the inner diameter of the mounting hole is the same as the outer diameter of the metal sleeve. The diameter matches. An axial keyway 1 is made on the side wall of the chuck front end, and the keyway is used to clamp a key 8 made on the outer surface of the metal sleeve.

[0022] The rear end of the chuck is coaxially connected with a handle, the handle is in the shape of a cylinder, and the outer diameter of the handle is greater than that of the chuck. For reducing weight, a through hole can be made coaxially in the inside of the hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com