Board quality detection real-time calculation system and method

A real-time computing and quality technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as index lag, product process quality missed inspection, product quality false inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

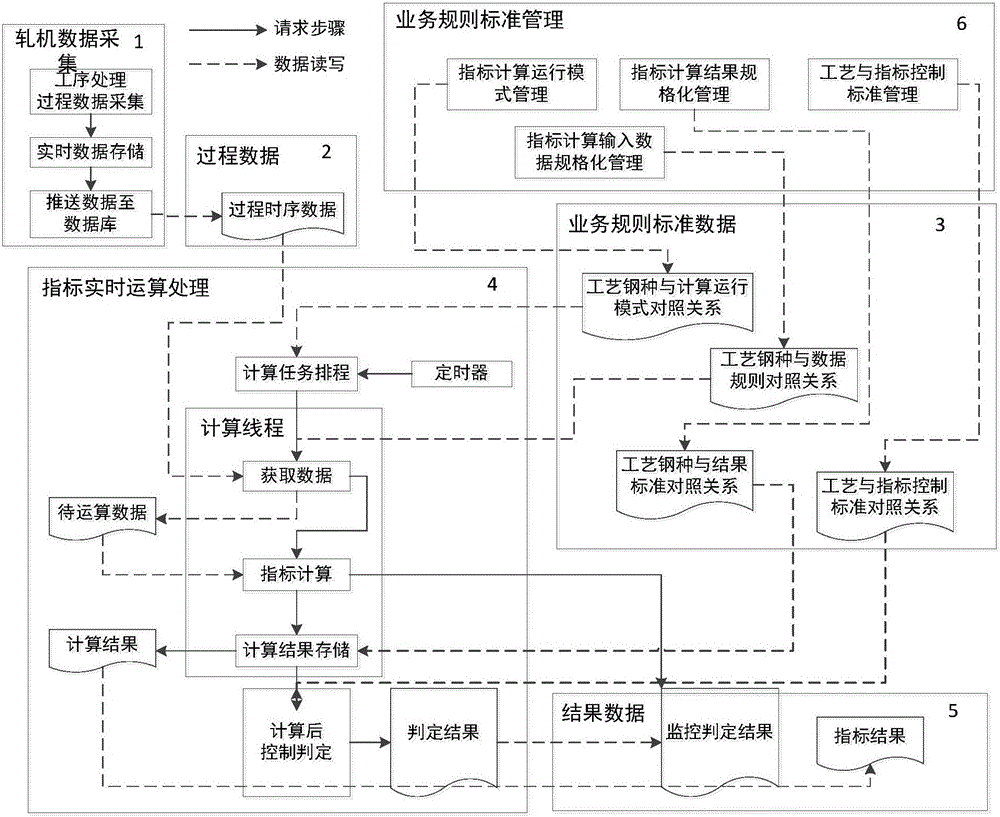

Method used

Image

Examples

Embodiment Construction

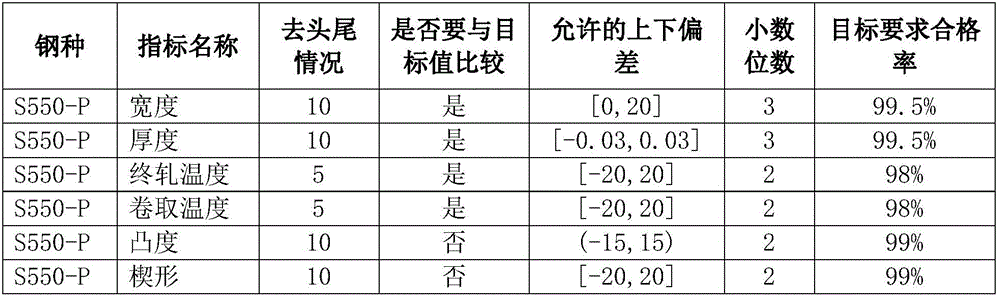

[0065] Implementation background:

[0066] In the hot rolling plant of a steel company, a calculation system for the quality inspection indicators of hot-rolled products was built. The process parameter "finishing temperature" of the automobile sheet (steel type is S550‐P) directly affects the comprehensive mechanical properties and texture of the finished sheet. The index calculation of the final rolling temperature is carried out when the steel coil is off-line, and only the index calculation is kept. The steel coil enters the next link.

[0067] Implementation build:

[0068] Rolling mill data collection: The hot rolling plant is arranged in series with six four-high finishing mills. The rolling mills have real-time data collection probes to collect curve data of the final rolling temperature.

[0069] Process database: store the final rolling temperature data in the insql real-time database, and store them in the form of time, tag name, and value. The position label is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com