Method for treating perchlorate in inorganic water body by using continuous flow anaerobic bioreactor

A technology of perchlorate and anaerobic organisms, applied in the field of water treatment, can solve the problems of affecting the removal effect of autotrophic reduction perchlorate, increasing the by-products of water supply disinfection treatment, hindering the release of electron donor hydrogen, etc., and achieving reduction Secondary pollution problem, reduction of sludge treatment cost, slow consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

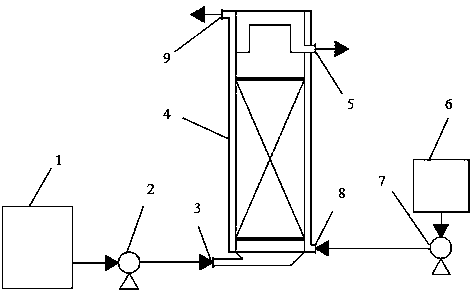

[0040] A packed reactor is used, and the volume ratio of zeolite and sulfur particles is alternately filled in the reactor packing layer at a ratio of 2:1 to a height of 20 cm. The particle size of the zeolite particle is 3 mm, and the particle size of the sulfur particle is 1 mm. Let the sludge domesticated by sulfur particles stand for 2 hours, take the sludge and fill it into the reactor filler (the amount of sludge finally accounts for 1 / 7 of the effective volume of the reactor), equipped with water pumps for perchlorate and inorganic salts Enter the reactor until the water body fills the reactor until it is close to the water outlet sampling port, let it stand for 2 days, and then start continuous water inflow, continuous flow anaerobic treatment of perchlorate, the water flow rate is maintained at 0.35 L / h, and the temperature of the treatment process is controlled at 26°C.

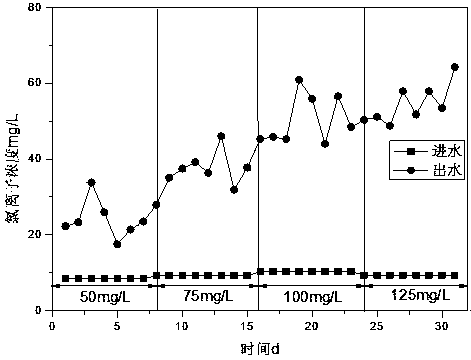

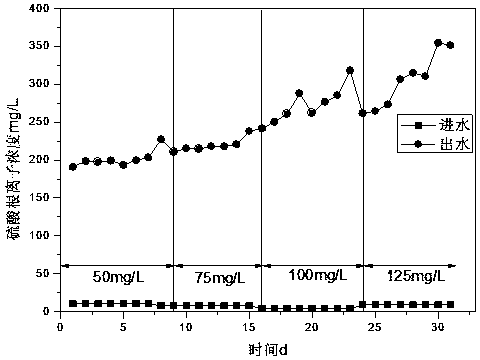

[0041] The initial concentration of perchlorate is controlled to be 50mg / L, and the concentratio...

Embodiment 2

[0044] A packed reactor is used, and the volume ratio of zeolite and sulfur particles is alternately filled in the reactor packing layer at a ratio of 3:1 to a height of 20 cm. The particle size of the zeolite particles is 3 mm, and the particle size of the sulfur particles is 3 mm. Let the sludge domesticated by sulfur particles stand for 3 hours, take the sludge and fill it into the reactor filler (the amount of sludge will eventually account for 1 / 5 of the effective volume of the reactor), equipped with water pumps for perchlorate and inorganic salts Enter the reactor until the water body fills the reactor until it is close to the water outlet sampling port, let it stand for 3 days, and then start continuous water intake, continuous flow anaerobic treatment of perchlorate, the water flow rate is 0.20L / h, and the temperature of the treatment process is controlled at 36°C.

[0045] The initial concentration of perchlorate is controlled at 140mg / L, and the concentration of eac...

Embodiment 3

[0048] A packed reactor is used, and the volume ratio of zeolite and sulfur particles is alternately filled in the reactor packing layer at a ratio of 2.5:1 to a height of 20 cm in the packing column. The particle size of the zeolite particle is 2 mm, and the particle size of the sulfur particle is 2 mm. Let the sludge domesticated by sulfur particles stand for 2.5 hours, take the sludge and fill it into the reactor filler (the amount of sludge finally accounts for 1 / 6 of the effective volume of the reactor), and the water body with perchlorate and inorganic salts Pump into the reactor until the water body fills the reactor until it is close to the water outlet sampling port, let it stand for 2.5 days, and then start continuous water inflow, continuous flow anaerobic treatment of perchlorate, water flow rate is 0.30L / h, and the temperature of the treatment process is controlled at 30°C.

[0049] The initial concentration of perchlorate is controlled to be 100mg / L, and the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com