Liquid path built-in compact aluminium-air fuel cell stack

A fuel cell stack, a compact technology, used in fuel cells, fuel cell additives, fuel cell half cells and primary cell half cells, etc., can solve the problem of increased battery current, complex structure, large size, etc. problem, to achieve the effect of long working time, small size and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

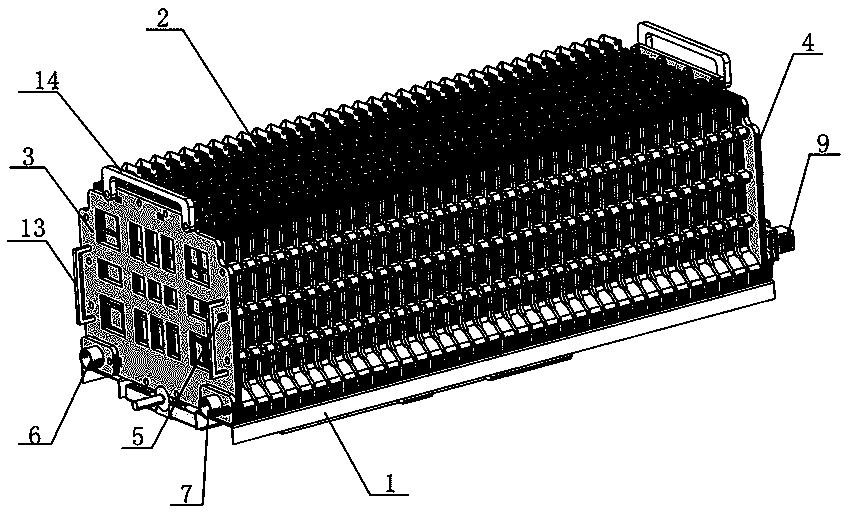

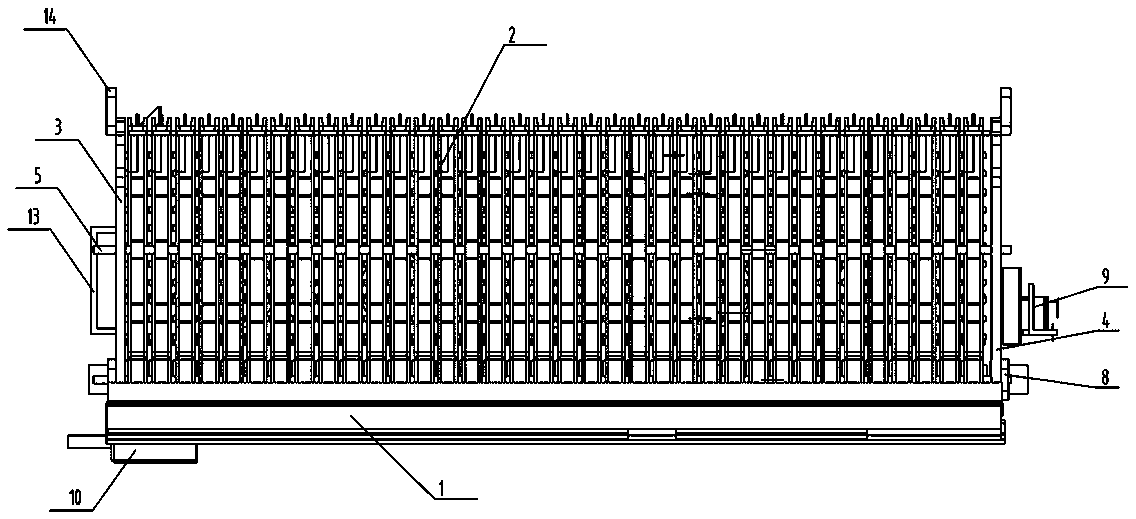

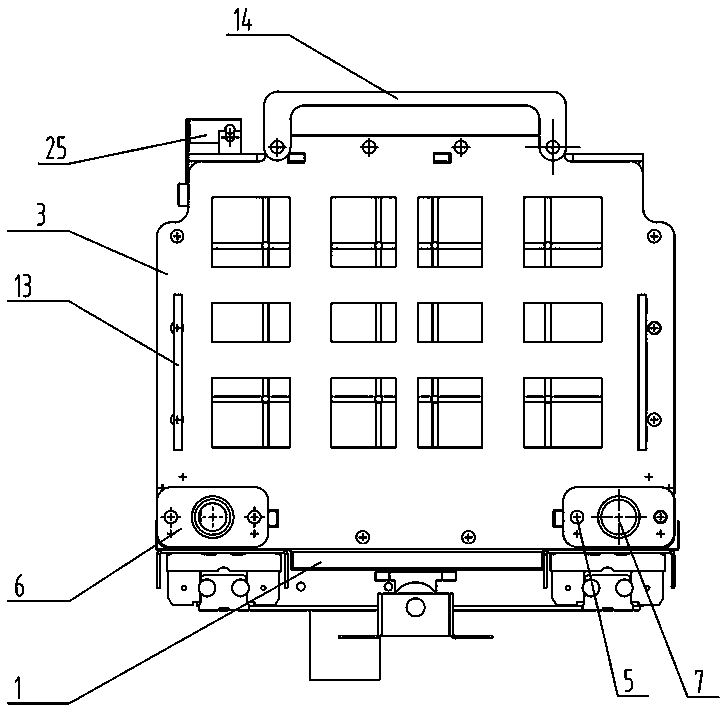

[0034] The orientations of front and rear, left and right, and up and down involved in the specific implementation of the present invention are described in the accompanying drawings figure 1 The display in is for reference.

[0035] Such as Figure 1~12 As shown, a compact aluminum-air fuel cell stack with a built-in liquid circuit includes a tray 1, and a battery cell group 2 composed of a group of battery cells is arranged in parallel above the tray 1. The battery cell group 2 consists of 36 A battery cell group 2 is formed, and the adjacent battery cells in the battery cell group 2 are closely bonded. The front and rear ends of the battery cell group 2 are provided with a front end plate 3 and a rear end plate 4, which run through the front end plate 3, The battery cell group 2 and the rear end plate 4 are provided with a set of tie bars 5; the front end plate 3 is provided with a liquid inlet port 6 and a liquid return port 7; the rear end plate 4 is provided with an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com