Plug-in vehicle battery busbar assembly

A busbar, plug-in technology, applied in the field of plug-in vehicle battery busbar assemblies, can solve the problems of large cross-sectional area of civilian busbars, unsuitable for vehicles, complex structure, etc., to improve service life and power efficiency. , the effect of ensuring reliability and reducing the probability of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

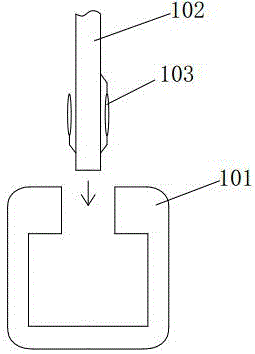

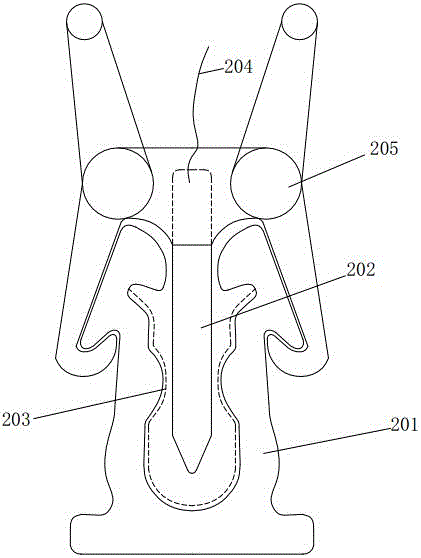

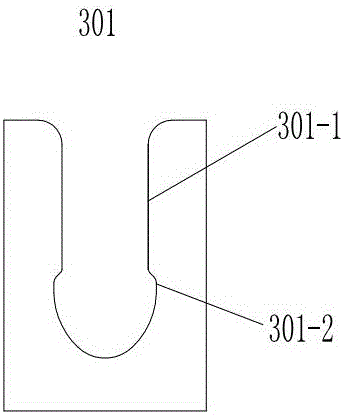

[0030] Such as Figure 3-6 As shown, the plug-in vehicle battery bus bar assembly of the present invention includes a round C-shaped bus bar 301 and one or two U-shaped elastic skewers 302; the round C-shaped bus bar 301 includes a straight section 301-1 and an arc Section 301-2, the opening width of the inner cavity of the straight section 301-1 is slightly smaller than the opening width of the inner cavity of the arc segment 301-2, and the inner cavity section of the arc segment 301-2 is C-shaped; the U-shaped elastic skewer head 302 includes straight Section 302-1 and circular crown section 302-2, circular crown section 302-2 is connected to the bottom of straight section 302-1, and the width of straight section 302-1 is slightly smaller than the width of circular crown section 302-2 base; U-shaped The width of the straight section 302-1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com