Segmented inclined-pole rotor and motor comprising same

A rotor and slanted pole technology, applied in the field of segmented slanted pole rotors and their motors, can solve the problems of excessive pole arc angle, affecting output power, overlapping of axially opposite magnetic poles, etc., to achieve low cogging torque and improve output. Torque and power density, effect of tilt angle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

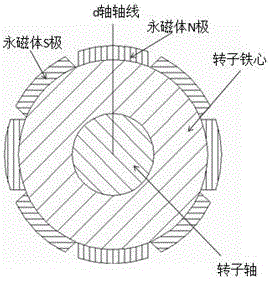

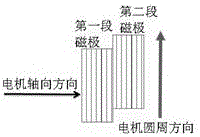

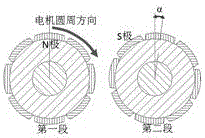

[0051] A segmented oblique pole rotor with 8 magnetic poles, which is divided into two rotor segments with the same length in the axial direction of the rotor, the angle between the first rotor segment and the second rotor segment in the circumferential direction is α1, α1= β×180 / LCM(Z1,2p), and 0.53≥ β≥0.5, where β is the segmental inclination ratio, and its rotor is a surface-type permanent magnet rotor structure and its permanent magnet adopts a tile-type structure, and its cross-sectional area has a tile-like structure. Sheet type, with 4 sides in total, two straight sides L1, L2 and two arc sides, the radii of the two arcs are R1 and R2 respectively, where 0.74×R2≥R1≥0.64×R2. The number of slots per pole and phase of the motor is 1, and the angle of each pole arc is the same, and is equal to π-πp / LCM (Z1, 2p) electrical angle, R2 is greater than or equal to H (H is the origin O to the inner arc edge of the permanent magnet ( The distance from the center of the arc edge) n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com