Method for improving saline-alkali soil of coastal mud flat by using charcoal cushion layer

A biochar, saline-alkali land technology, applied in land preparation methods, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of unstable improvement effect, change of soil properties, interference with air entering, etc., to alleviate the dilemma of saline-alkali soil improvement, Effects of improving soil physical and chemical properties and controlling agricultural non-point source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

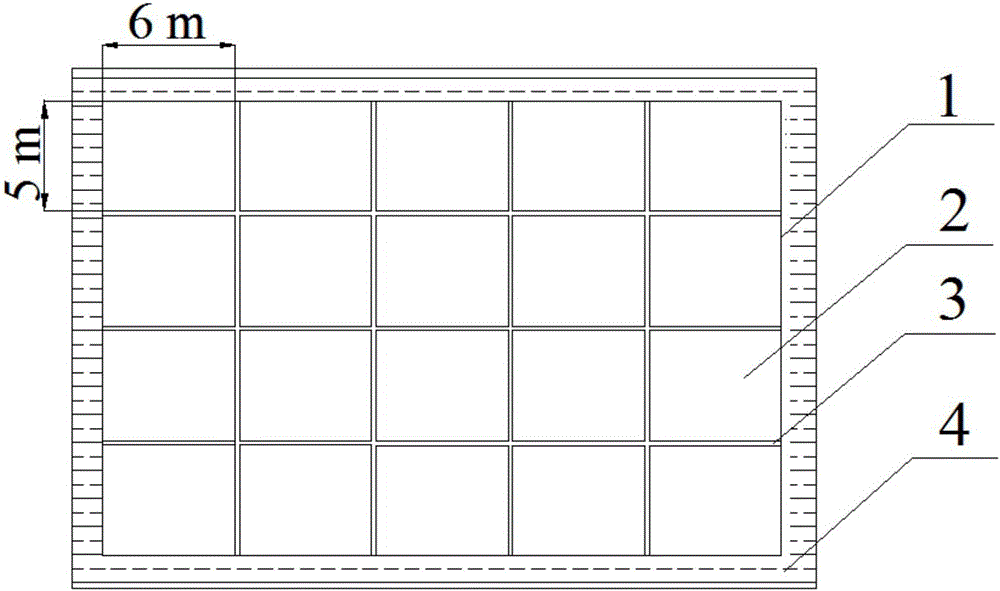

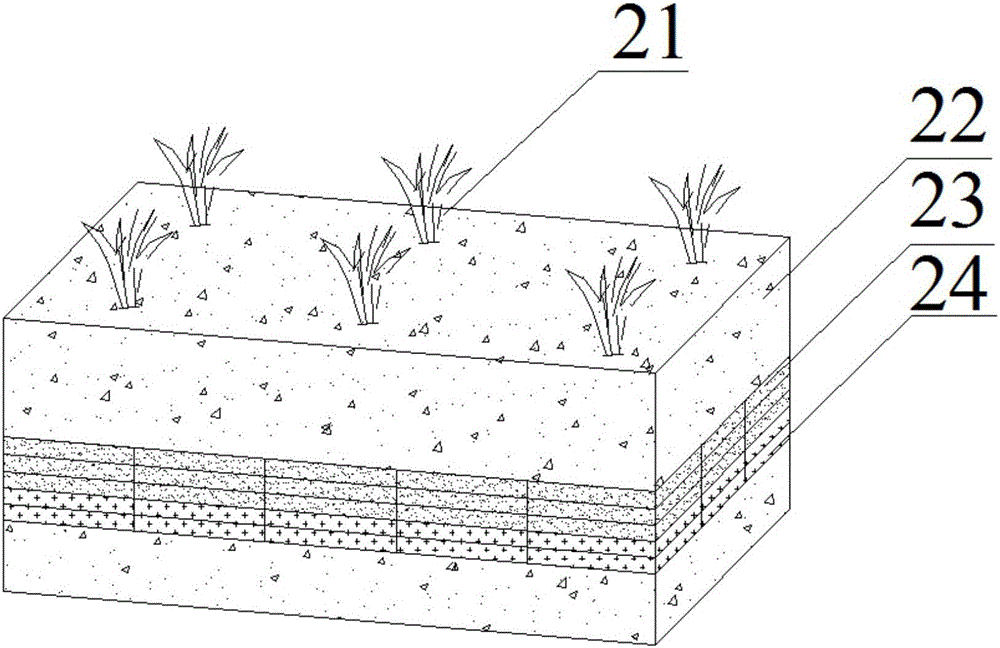

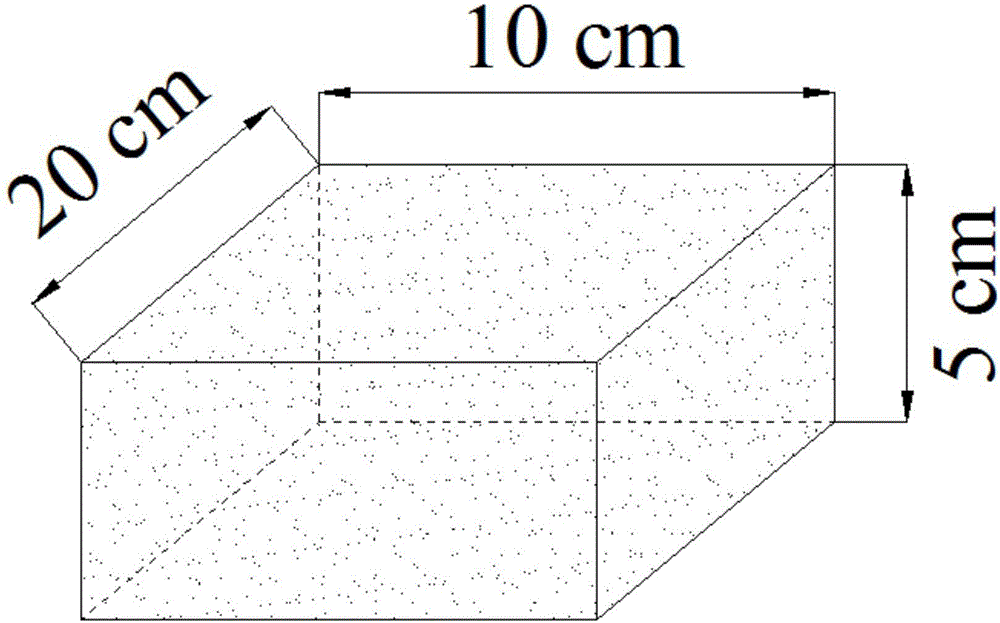

[0043] Plan the improvement area, divide the improvement unit after leveling the land, and then grid it into an improvement plot of 5m×6m, and the interval width between the improvement plots is 0.2m; excavate the saline-alkali soil of the improvement plot to a depth of 40cm to form a biochar cushion pit foundation ;In the pit foundation, firstly lay the biochar cushion layer B composed of the biochar module B from bottom to top, with a thickness of 5cm, and then lay the biochar cushion layer A composed of the biochar module A, with a thickness of 5cm. The outside of the biochar module A is a degradable film, and the inside is a mixed biochar A with a particle size of less than 1mm. Woody biochar accounts for 70% of the total volume, and other biochar accounts for 30% of the total volume; The outside is a degradable film, and the inside is a mixed biochar B with a particle size of 1-2mm. Woody biochar accounts for 30% of the total volume, and other biochar accounts for 70% of t...

Embodiment 2

[0047] Plan the improvement area, divide the improvement unit after leveling the land, and then grid it into an improvement plot of 5m×6m. ;In the pit foundation, firstly lay the biochar cushion layer B composed of biochar module B from bottom to top, with a thickness of 10cm, and then lay the biochar cushion layer A composed of biochar module A, with a thickness of 10cm. The outside of the biochar module A is a degradable film, and the inside is a mixed biochar A with a particle size of less than 1mm. Woody biochar accounts for 60% of the total volume, and other biochar accounts for 40% of the total volume; The outside is a degradable film, and the inside is a mixed biochar B with a particle size of 1-2mm. Woody biochar accounts for 40% of the total volume, and other biochar accounts for 60% of the total volume.

[0048] Backfill the topsoil and turn it evenly; drain the salt 4 times to get the improved soil, which can be used for planting vegetables.

[0049] Ditches with a w...

Embodiment 3

[0051] Plan the improvement area, divide the improvement unit after leveling the land, and then grid it into an improvement plot of 5m×6m, and the interval width between the improvement plots is 0.2m; excavate the saline-alkali soil on the surface of the improvement plot to 45cm to form a biochar cushion pit foundation ; In the pit foundation, first lay the biochar cushion B composed of biochar module B from bottom to top, with a thickness of 5cm, and then lay the biochar cushion A composed of biochar module A, with a thickness of 15cm. The outside of the biochar module A is a degradable film, and the inside is a mixed biochar A with a particle size of less than 1mm. Woody biochar accounts for 50% of the total volume, and other biochar accounts for 50% of the total volume; The outside is a degradable film, and the inside is a mixed biochar B with a particle size of 1-2mm. Woody biochar accounts for 50% of the total volume, and other biochar accounts for 50% of the total volume....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com