Anti-fake carbon belt and recycling device

A technology for recycling devices and carbon ribbons, which is applied in the direction of inking devices, ink ribbons, printing, etc., can solve the problems of easy falling off of toner, easy counterfeiting of finished products, waste of resources, etc., and achieves good anti-counterfeiting effects, better stripping effects, and improved The effect of the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

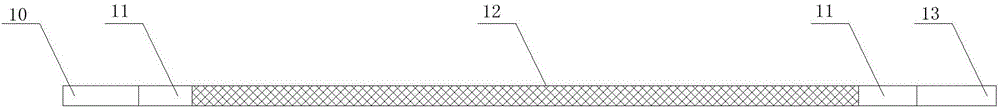

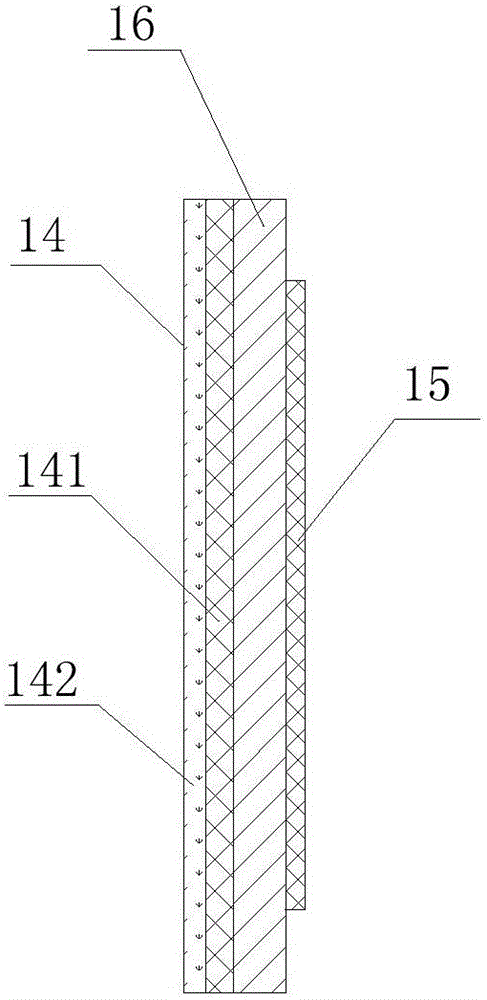

[0074] The anti-counterfeiting carbon tape provided in this embodiment includes a tape base 16, and two surfaces of the tape base 16 are respectively covered with an ink layer 15 and a back coating layer 14;

[0075] The belt base 16 includes a starting end 10, a powder removal section 11, a printing section 12 and a winding terminal 13;

[0076] The ink layer 15 is a transferable anti-counterfeiting ink and is evenly coated on the surface of the printing section 12;

[0077] The powder removal section 11 is arranged at a portion of the belt base 16 that is easy to be powdered.

[0078] The ink layer 15 includes the following weight ratio components:

[0079] 25% resin, 20% anti-counterfeiting material, 20% paraffin wax, 18% colorant, 15% pigment and 2% additives.

[0080] The auxiliary agent is a mixture of anti-offset agent, heat inhibitor and slip agent. The volume ratio of the anti-offset agent, heat inhibitor and slip agent when mixed is 0.8:0.8:0.6.

Embodiment 2

[0082] The anti-counterfeiting carbon tape provided in this embodiment includes a tape base 16, and two surfaces of the tape base 16 are respectively covered with an ink layer 15 and a back coating layer 14;

[0083] The belt base 16 includes a starting end 10, a powder removal section 11, a printing section 12 and a winding terminal 13;

[0084] The ink layer 15 is a transferable anti-counterfeiting ink and is evenly coated on the surface of the printing section 12;

[0085] The powder removal section 11 is arranged at a portion of the belt base 16 that is easy to be powdered.

[0086] The ink layer 15 includes the following weight ratio components:

[0087] 28% resin, 22% anti-counterfeiting material, 18% paraffin wax, 18% colorant, 12% pigment and 2% additives.

[0088] The auxiliary agent is a mixture of anti-offset agent, heat inhibitor and slip agent. The volume ratio when the anti-offset agent, heat inhibitor and slip agent are mixed is 1:0.8:0.8.

Embodiment 3

[0090] The anti-counterfeiting carbon tape provided in this embodiment includes a tape base 16, and two surfaces of the tape base 16 are respectively covered with an ink layer 15 and a back coating layer 14;

[0091] The belt base 16 includes a starting end 10, a powder removal section 11, a printing section 12 and a winding terminal 13;

[0092] The ink layer 15 is a transferable anti-counterfeiting ink and is evenly coated on the surface of the printing section 12;

[0093] The powder removal section 11 is arranged at a portion of the belt base 16 that is easy to be powdered.

[0094] The ink layer 15 includes the following weight ratio components:

[0095] Resin 28%, anti-counterfeiting material 25%, paraffin 15%, coloring agent 20%, pigment 11% and auxiliary agent 1%.

[0096] The auxiliary agent is a mixture of anti-offset agent, heat inhibitor and slip agent. The volume ratio when the anti-offset agent, heat inhibitor and slip agent are mixed is 1:1:0.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com