A high-voltage positive electrode sheet and its preparation method

A high-voltage, positive electrode technology, applied in the direction of electrode manufacturing, battery electrodes, electrode collector coating, etc., can solve the problems of ignoring the design of positive electrodes, achieve high-current charging and discharging, high conductivity efficiency, and improve charging and discharging efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

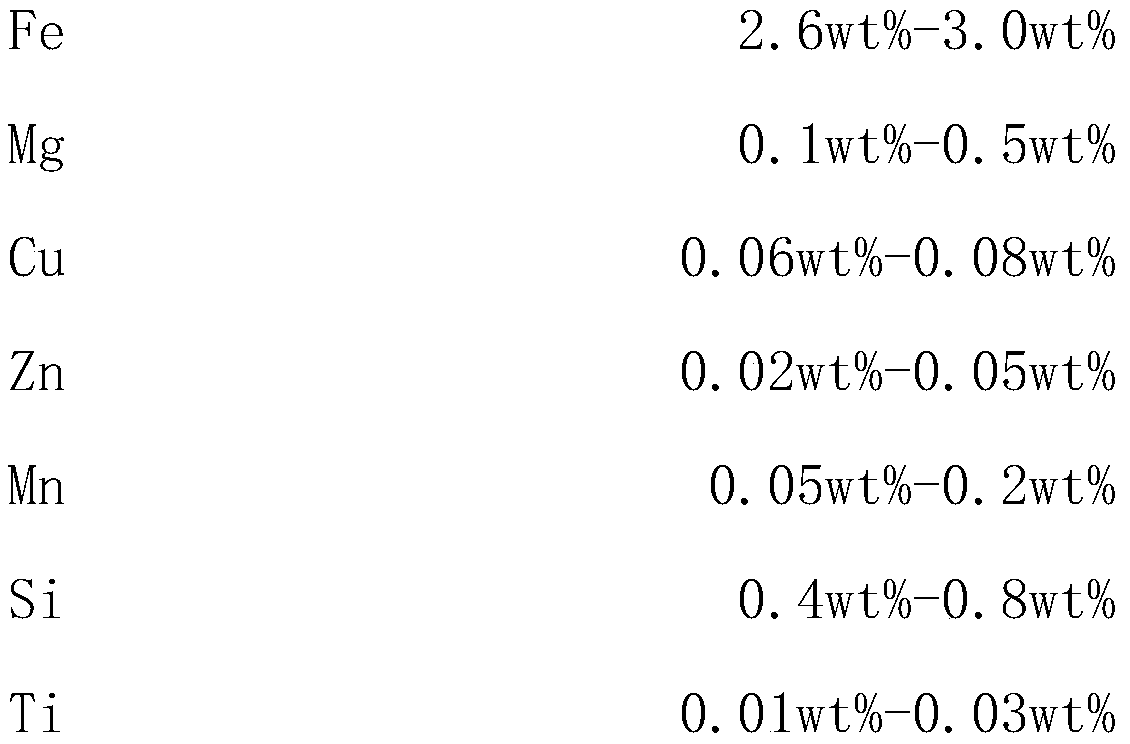

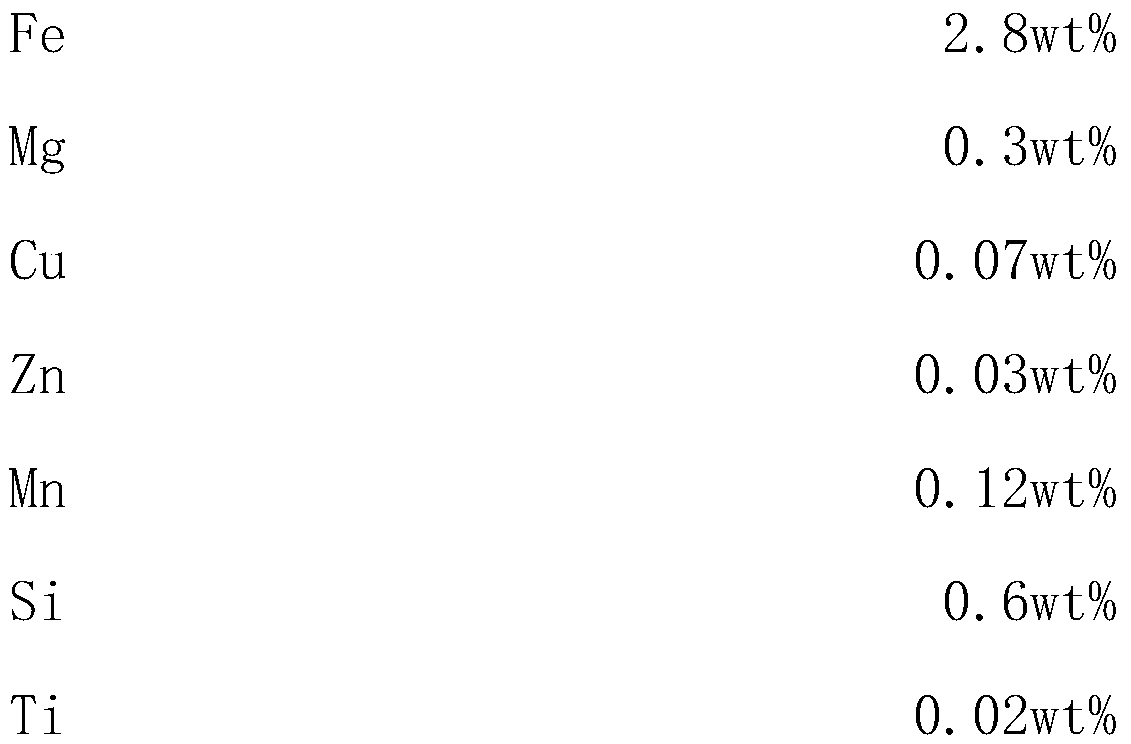

Embodiment 1

[0029] A high-voltage positive electrode sheet, comprising a positive electrode current collector and a positive electrode slurry layer coated on the surface of the positive electrode current collector, the positive electrode slurry layer is composed of 92.5wt% positive active material, 5.5wt% composite conductive agent and 2wt% The binder is prepared by carbonization treatment, and the composite conductive agent is composed of 68wt% cellulose, 30wt% graphene and 2wt% aluminum powder.

[0030] Wherein, the length of the cellulose is 30 μm, the diameter is 200 nm, the average particle size of the graphene is 55 nm, the BET surface area is 600 m2 / g, and the particle size of the aluminum powder is 40 nm.

[0031] Wherein, the binder is polyvinylidene fluoride.

[0032] Wherein, the positive electrode active material is LiNi x co y mn z o 2 , where x=0.3, y=0.5, z=0.2.

[0033] Wherein, the particle size distribution D50 of the positive electrode active material is 13 μm.

...

Embodiment 2

[0045] A high-voltage positive electrode sheet, comprising a positive electrode current collector and a positive electrode slurry layer coated on the surface of the positive electrode current collector, the positive electrode slurry layer is composed of 87wt% positive active material, 10wt% composite conductive agent and 3wt% viscose The composite conductive agent is prepared by carbonizing the binder, and the composite conductive agent is composed of 57wt% cellulose, 40wt% graphene and 3wt% aluminum powder.

[0046] Wherein, the length of the cellulose is 10 μm, the diameter is 100 nm, the average particle size of the graphene is 10 nm, the BET surface area is 800 m2 / g, and the particle size of the aluminum powder is 30 nm.

[0047] Wherein, the binder is polyvinylidene fluoride.

[0048] Wherein, the positive electrode active material is LiNi x co y mn z o 2 , where x=0.26, y=0.44, z=0.3.

[0049] Wherein, the particle size distribution D50 of the positive electrode act...

Embodiment 3

[0062] A high-voltage positive electrode sheet, including a positive electrode current collector and a positive electrode slurry layer coated on the surface of the positive electrode current collector, the positive electrode slurry layer is composed of 98wt% positive electrode active material, 1wt% composite conductive agent and 1wt% viscose The composite conductive agent is prepared by carbonizing the binder, and the composite conductive agent is composed of 79wt% cellulose, 20wt% graphene and 1wt% aluminum powder.

[0063] Wherein, the length of the cellulose is 50 μm, the diameter is 300 nm, the average particle size of the graphene is 100 nm, the BET surface area is 400 m2 / g, and the particle size of the aluminum powder is 49 nm.

[0064] Wherein, the binder is polyvinylidene fluoride.

[0065] Wherein, the positive electrode active material is LiNi x co y mn z o 2 , where x=0.33, y=0.61, z=0.6.

[0066] Wherein, the particle size distribution D50 of the positive elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com