Obstacle-crossing mechanism of rod piece climbing robot

A technology of robots and rods, which is applied in the climbing field of power transmission systems, can solve the problems that the opening size of the jaws is difficult to adapt to the change in diameter, the robot's adaptability to the diameter of rods is reduced, and the versatility and applicability are poor, so as to achieve good flexibility. , low production cost, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

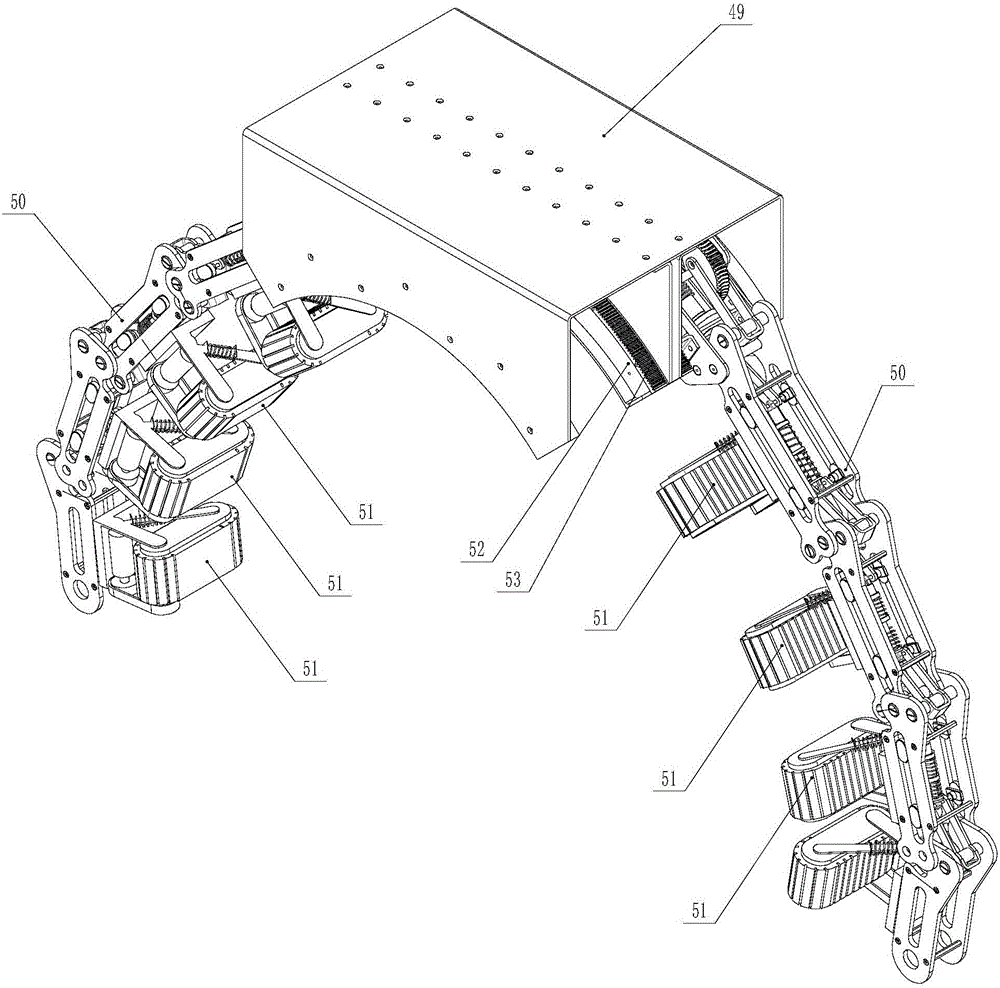

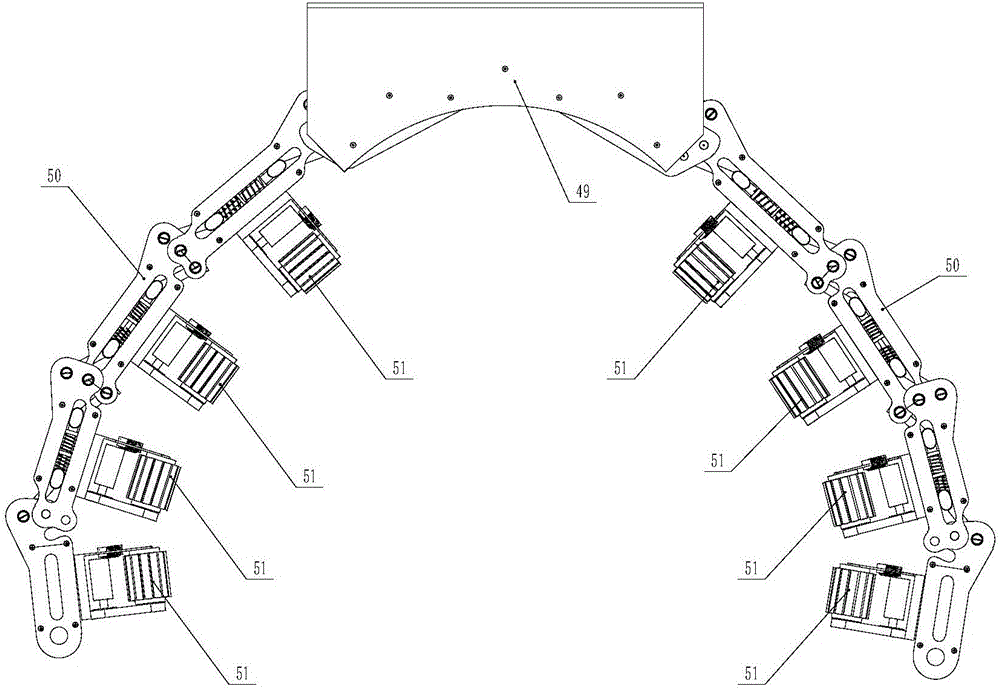

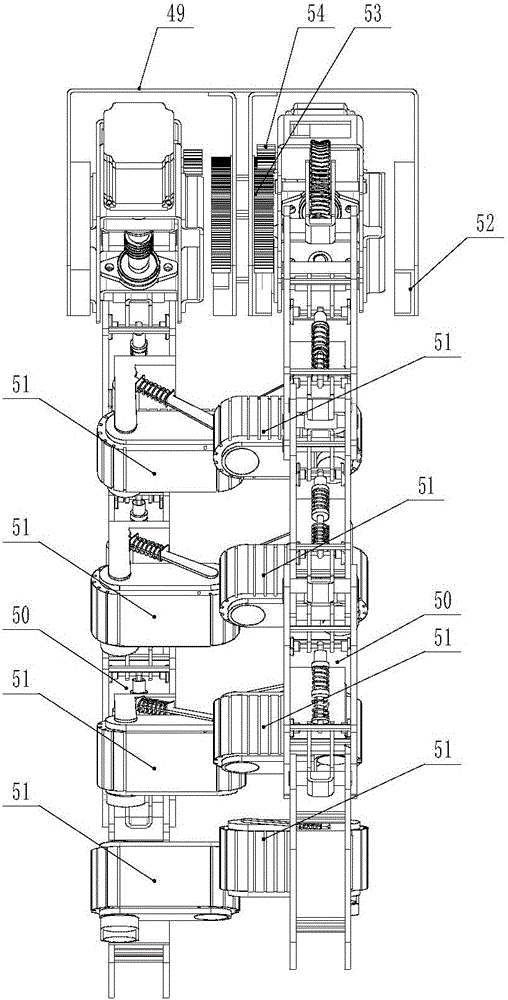

[0025] refer to Figure 1-10 As shown, a bar climbing robot obstacle-climbing mechanism includes a fuselage 49, an embracing mechanism 50 and a climbing mechanism 51. The fuselage 49 is provided with two arc-shaped guide grooves 52 arranged side by side. There are two embracing mechanisms 50 , and the two embracing mechanisms 50 are arranged opposite to each other and coaxially cooperate with a guide groove 52 respectively. The climbing mechanism 51 is arranged on the embracing mechanism 50 .

[0026] The encircling mechanism 50 includes a drive mechanism, an encircling executive mechanism and an encircling force application mechanism. The drive mechanism includes a box body 1, a stepping motor 2, a shaft coupling 3, a rear bearing seat 4, a front bearing seat 5, a worm 6, Incomplete worm gear 7, worm gear shaft 8, main push rod 9, push rod shaft 10 and circlip, the stepping motor 2 is fixed on the rear end of the box body 1, and the stepping motor 2 is connected to the worm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com