Preparation process of two-component flash color twill sofa cloth fabric

A preparation process and sofa release technology, which is applied in the processing of textile materials, fabric surface trimming, liquid/gas/steam textile material processing, etc., and can solve knife marks, holes, knife strips, poor stability, and poor balance and other problems, to achieve the effect of high shearing frequency, good lifting performance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

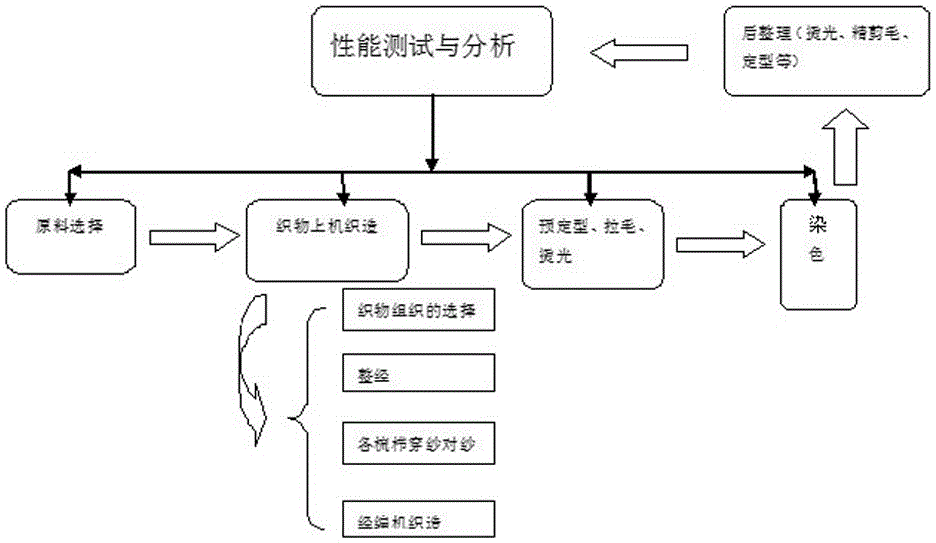

[0011] as attached figure 1 Shown, a kind of preparation technology of two-component flashing color twill sofa fabric, comprises raw material selection, weaving, napping, dyeing, ironing and finishing steps, and described weaving step comprises the selection of fabric structure, warping, each combing Bar-threaded yarn-to-yarn and warp knitting machine weaving, using three bar weaving, GB1 uses 50D / 24F polyester filament; GB2 uses 75D / 36F polyester filament; GB3 uses 75D / 36FFDY flat yarn and 75D / 36FFDY cationic Silk. The number of times of raising in the napping step is 8 times. In terms of machine matching, the 1st and 3rd raising machines are selected with 24-roller raising machines, and from the 4th to the 8th, 36-roller raising machines are selected. After the raising machine has raised the hair strongly, the loops on the fabric have been pulled out, and the bottom of the fabric has been loosened and softened. The number of times of scalding is 4 times, which are 2 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com