Coring drilling machine mast adjusting mechanism

A technology of adjusting mechanism and mast, which is applied in the direction of drilling equipment, earthwork drilling, extracting undisturbed core devices, etc., can solve the problems of low adjustment accuracy, affect operation quality, and low adjustment efficiency, and achieve high adjustment accuracy, improve operation quality and efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

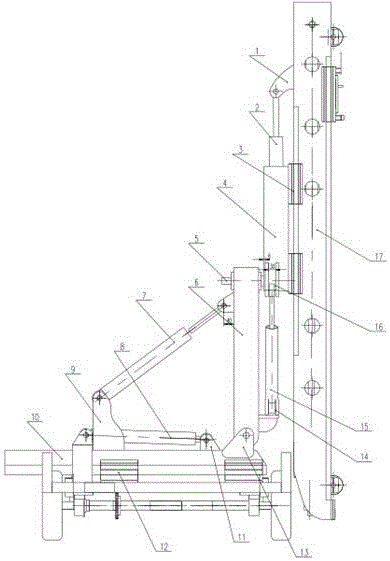

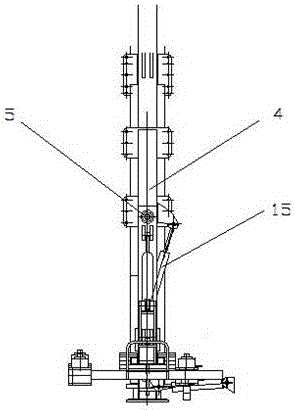

[0014] Such as figure 1 with figure 2 As shown, a mast adjustment mechanism of a coring drilling rig of the present invention includes a lifting cylinder 4, a connecting rod 6, a front and rear angle adjustment cylinder 15, and a mast 17; The mast 17 is provided with a guide rail 13, and the lower part of the cylinder body of the lifting cylinder 4 is connected with the connecting rod 6 through the pin shaft 5, and the connecting rod 6 is installed on the vehicle frame; 14, the other end is hinged on the ear seat six 16 on one side of the lift cylinder 4, and the front and rear angle adjustment oil cylinder 15 is telescopic, so that the mast 17 is rotated forward and backward with the bearing pin 5 as the center to adjust the angle. Here, the front and rear directions are figure 1 in the front-back direction (i.e. figure 2 in the left-right direction). When working, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com