Two-stage pressure-type hydro-pneumatic spring and working method thereof

A kind of oil and gas spring, pressure type technology, applied in the direction of spring, spring/shock absorber, shock absorber, etc., can solve the problem that the performance of oil and gas spring cannot be guaranteed, and the sealing performance of floating piston is very high, so as to reduce the sealing requirements and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

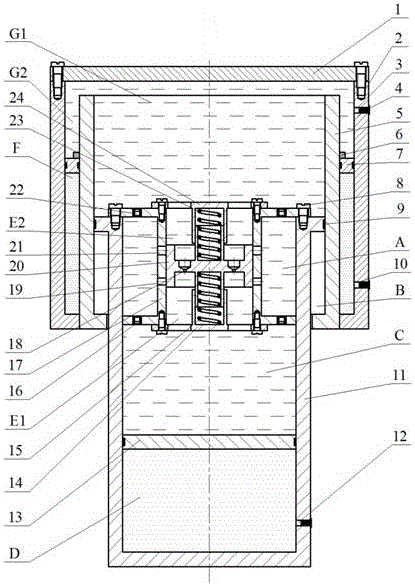

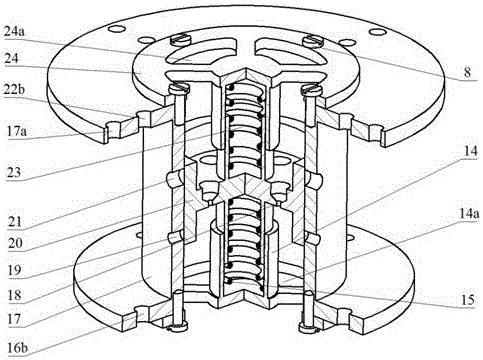

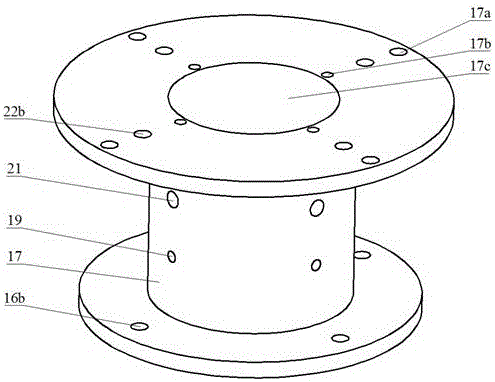

[0026] see figure 1, the two-stage pressure oil-gas spring of the present invention has an outer cylinder 2, the top of the outer cylinder 2 is sealed and connected to the cylinder head 1, and there is a sealing gasket between the top of the outer cylinder 2 and the cylinder head 1 and is fixedly connected by a bolt assembly

[0027] An inner cylinder 5 is coaxially nested inside the outer cylinder 2, and the piston rod 11 extends upwards into the inner cylinder 5 from the bottom of the outer cylinder 2 and the inner cylinder 5, and the outer cylinder 2, the inner cylinder 5, The three of piston rod 11 are coaxial.

[0028] The bottom of the outer cylinder 2 and the bottom of the inner cylinder 5 are connected by welding to form a sealed whole, which needs to be guaranteed to have good sealing performance.

[0029] The top of the inner cylinder 5 is open and is not connected with the cylinder head 1. The opening position of the top of the inner cylinder 5 is lower than the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com