Tire burst detection method and cavity type tire burst sensor

A tire blowout sensor and tire blowout technology, applied in the field of tire blowout detection, can solve the problems of reducing the size and weight of tire blowout and tire pressure monitoring modules, so as to facilitate large-scale mass production and meet long-term low power consumption and stable work , the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

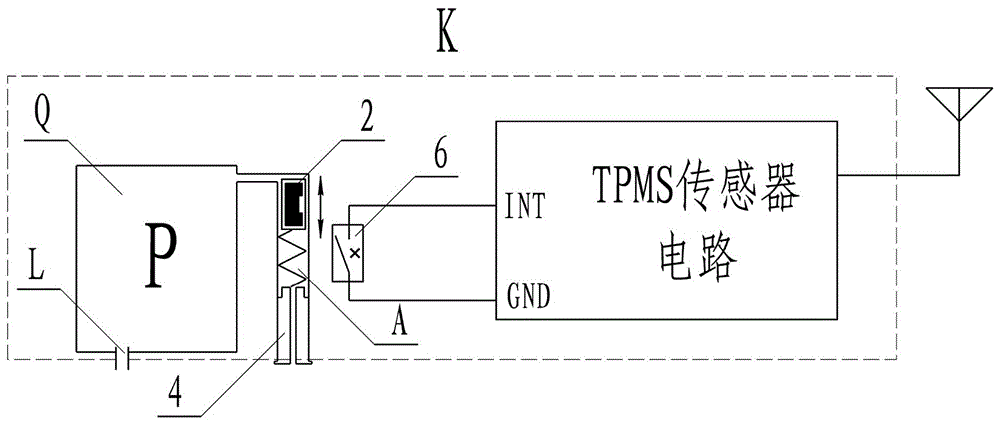

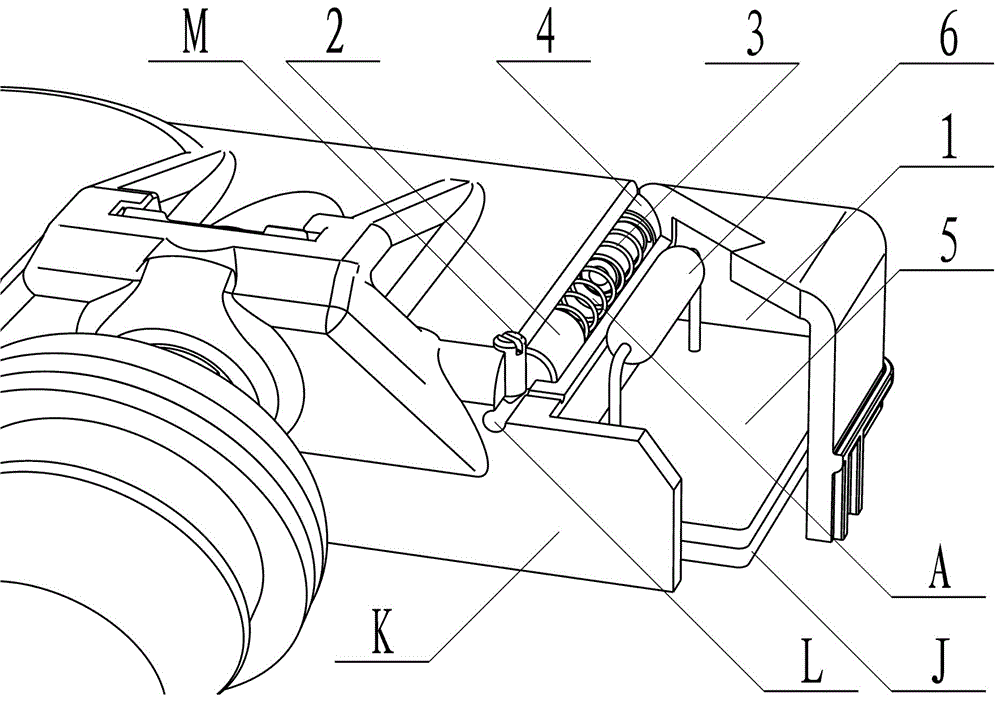

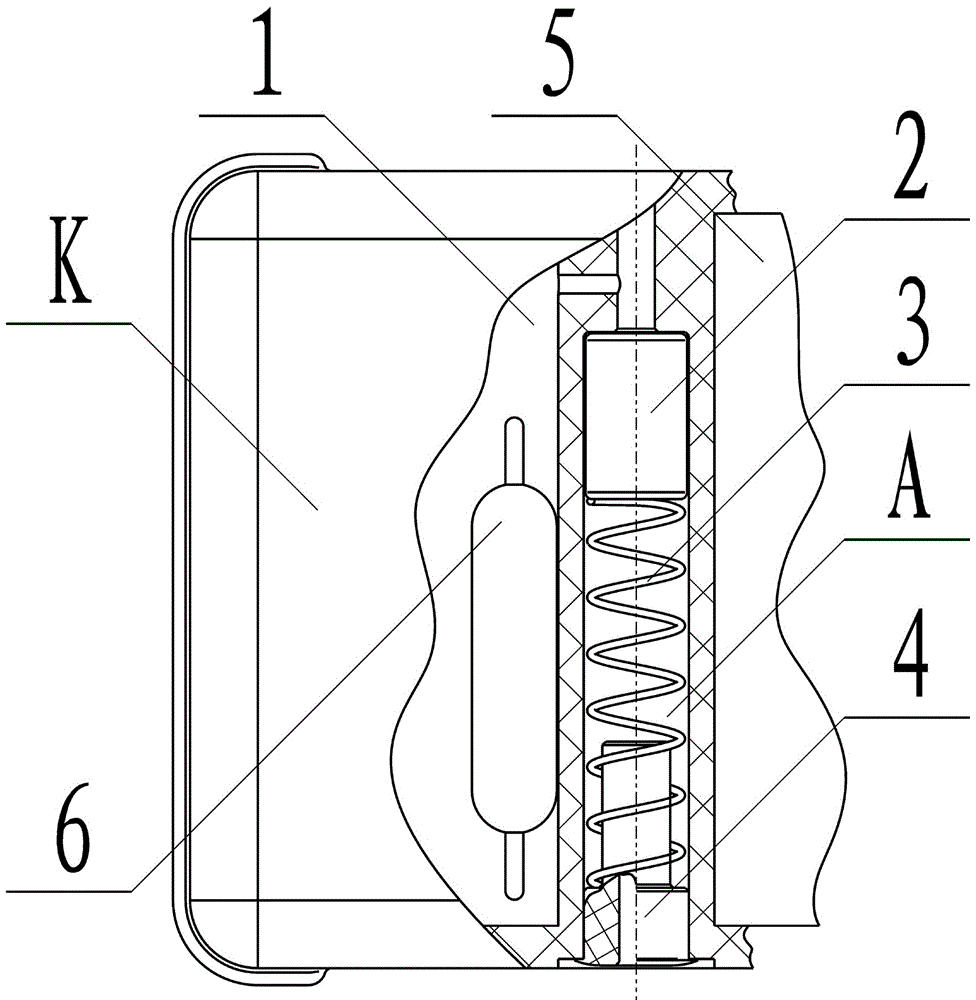

[0017] Combine below figure 1 , figure 2 , image 3 The tire burst sensor of Embodiment 1 of the present invention will be described in detail.

[0018] The tire burst sensor consists of a semi-open chamber (1), a permanent magnet piston (2), a spring (3), a plug (4), and a PCB board (5) arranged in the tire burst and tire pressure monitoring module housing (K). It is composed of a reed switch (6); a tube-shaped air passage (A) connected to the semi-open cavity (1) and parallel to the wheel axis is provided in the tire burst and tire pressure monitoring module housing (K); in the semi-open The cavity (1) is provided with a measuring hole (L) passing through the semi-open cavity (1); the measuring hole (L) is adjusted to achieve the dynamic characteristics required by different tire pressures through the screw (M) for adjusting the flow rate; The permanent magnet piston (2) is a permanent magnet whose surface is wrapped or coated with a solid lubricating material (such as: ...

Embodiment 2

[0021] Combine below figure 1 , figure 2 , image 3 The tire burst sensor of Embodiment 2 of the present invention will be described in detail.

[0022] As a change, the measuring hole (L) of embodiment 2 is arranged in the tubular air passage (A), and the permanent magnetic piston (2) is not coated with silicone grease, and is installed in a dry manner. By accurately adjusting the permanent magnetic piston (2 ) cooperates with the gap of the tubular air channel (A) to realize the adjustment function of the flow rate of the metering hole (L), and can also reduce the adjustment links; the magnetic sensitive switch can also choose an active Hall switch;

[0023] Although embodiment 2 has made some adjustments on the structure of the measuring hole. Relative to embodiment 1, there is no essential change; the installation of the tire burst sensor in embodiment 2, and the tire burst monitoring method of the tire burst sensor are all the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com