Method for rapidly detecting bending strength of furan resin-sand

A technology of furan resin and bending strength, which is applied in the field of casting, can solve the problems of unguided production, long time consumption, poor timeliness, etc., and achieve the effect of saving process steps, simple production and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

[0030] Take ten kinds of furan resin sands with a sand mixing machine, which are the first kind of furan resin sand, the second kind of furan resin sand...the tenth kind of furan resin sand, under the same experimental conditions:

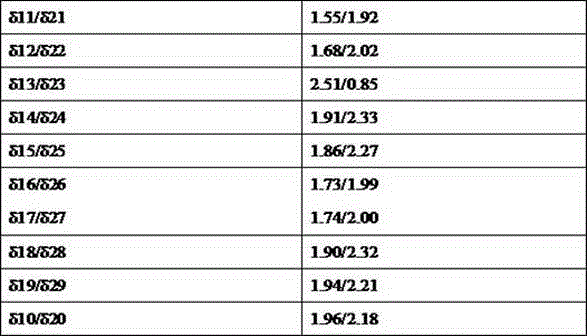

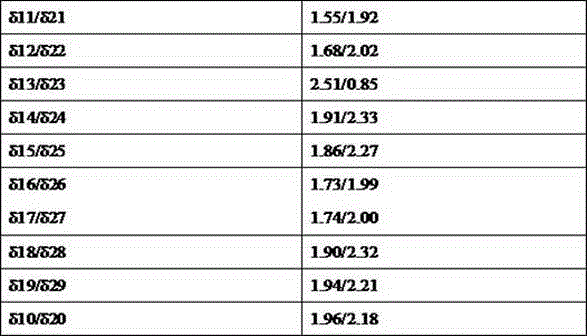

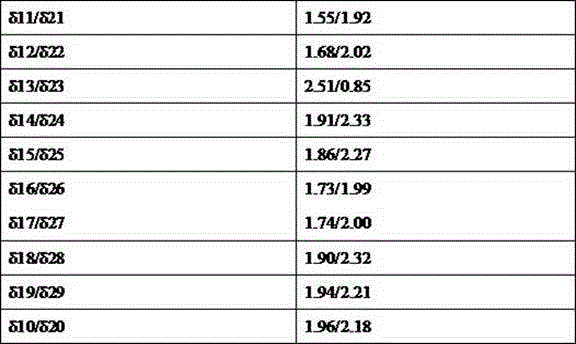

[0031] (1) Measure the strength value δ11 of the first furan resin sand according to the requirements of the first step to step seven, and measure the first furan resin sand according to the requirements of the national standard sample. Get the intensity value of first kind of furan resin sand δ21;

[0032] (2) Measure the strength value δ12 of the second furan resin sand according to the requirements of step 1 to step 7, and measure the second furan resin sand according to the requirements of the national standard sample. Get the intensity value of the second kind of furan resin sand δ22; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com