Freezing and cryogenic impact testing device for Hopkinson pressure bar

A Hopkinson pressure bar, low temperature impact technology, applied in the direction of using one impact force to test the strength of materials, preparation of test samples, etc., can solve the problems of large environmental disturbance in low temperature test, difficult processing and installation, low test efficiency , to achieve the effect of good test operation effect, convenient installation and improvement of low temperature treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This embodiment is a freezing and low-temperature impact test device for a Hopkinson compression bar.

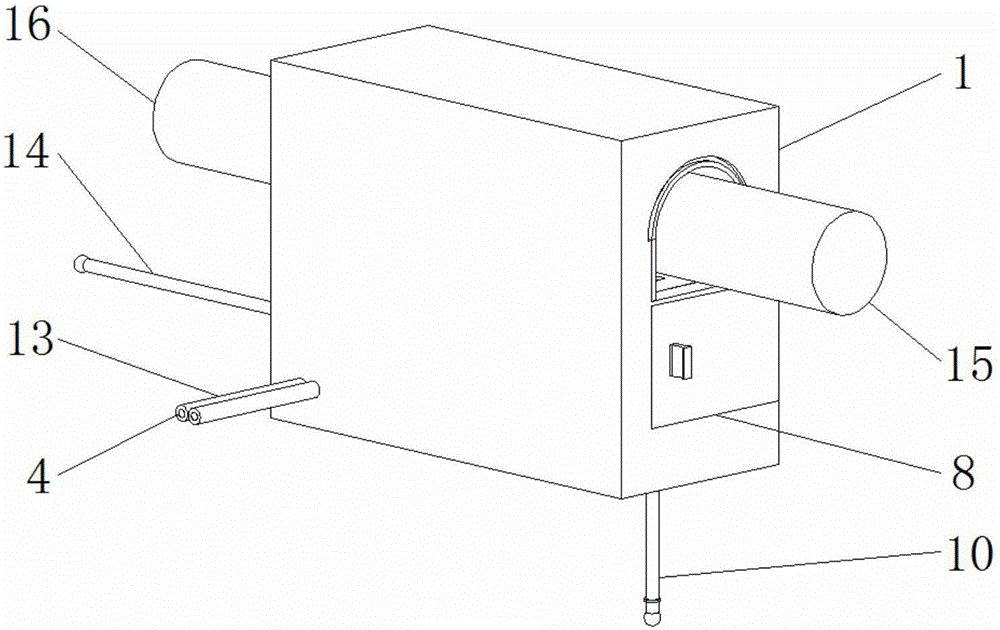

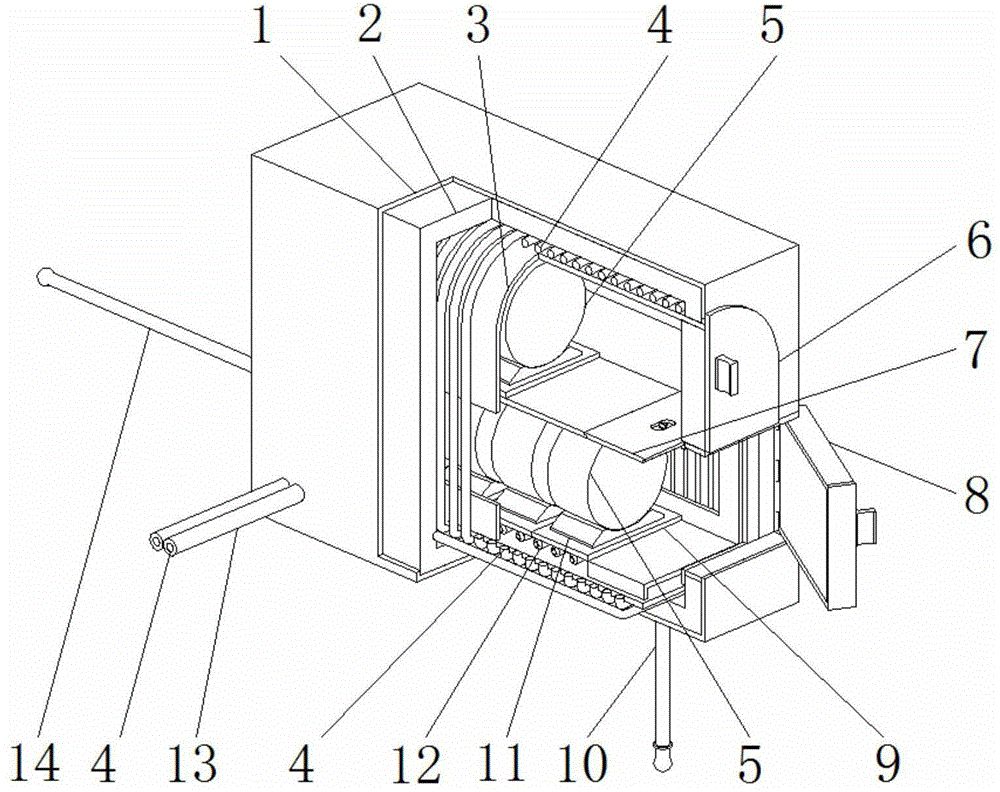

[0031] Such as figure 1 , this embodiment is used in conjunction with the incident rod 15 and the transmission rod 16 of the separated Hopkinson compression rod experimental device, providing a freezing and low-temperature impact test device for the separated Hopkinson compression rod.

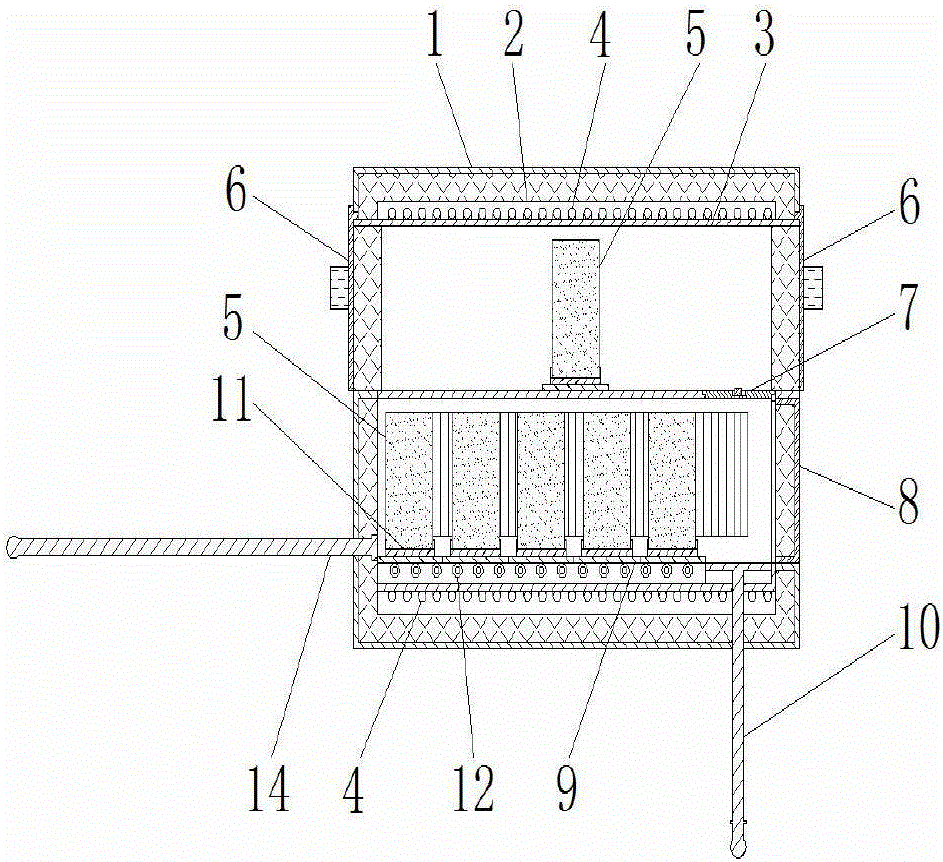

[0032] This embodiment includes a low-temperature experiment cabin 3, a condensation pipe 4, two airtight doors 6, a movable door 8, a push rod 14 and a bracket 10, a plurality of arc pads 11 and a plurality of trays 9, rollers 12 and partitions 7; The number of the arc pads is the same as the number of pallets. The low temperature experiment chamber 3 includes an upper test chamber and a lower test chamber, and the upper test chamber and the lower test chamber are separated by a partition 7 . The cross-section of the upper test chamber is horseshoe-shaped, which is used for low-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com